Preparation method of super-hydrophobic preservative treated wood

A super-hydrophobic, wood technology, applied in wood treatment, wood heating, wood impregnation, etc., can solve the problem of short duration of anti-corrosion and hydrophobic effect, and achieve the effects of increasing anti-corrosion performance, good bacteriostatic effect and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

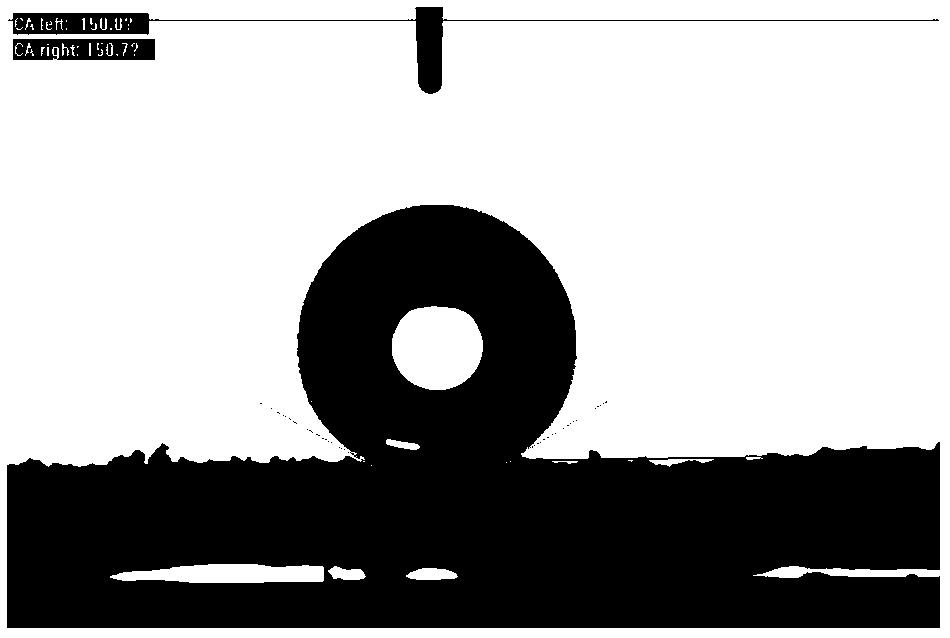

[0038] The superhydrophobic preservative wood in the present embodiment comprises wood matrix (being the masson pine wood chip), and the inside of this wood matrix is impregnated with nano-Cu 2 O particles, coated with a superhydrophobic coating. The above-mentioned super-hydrophobic coating is a vinyltriethoxysilane hydrolysis film layer. The preparation method of above-mentioned superhydrophobic preservative wood comprises the following steps:

[0039] (1) Dissolve 2g of copper acetate monohydrate in 100mL of water, stir magnetically for 10min with slight heating, then add 1.8gD-glucose and 0.3g of K-30PVP under magnetic stirring conditions, and continue stirring for 20min to obtain a mixed solution system;

[0040] (2) Take 70mL of the mixed solution system obtained in step (1) in the reactor liner, put masson pine wood chips at the same time, and then heat the reactor at 120°C for 6h;

[0041] (3) After the reaction kettle is lowered to room temperature, the wood chips...

Embodiment 2

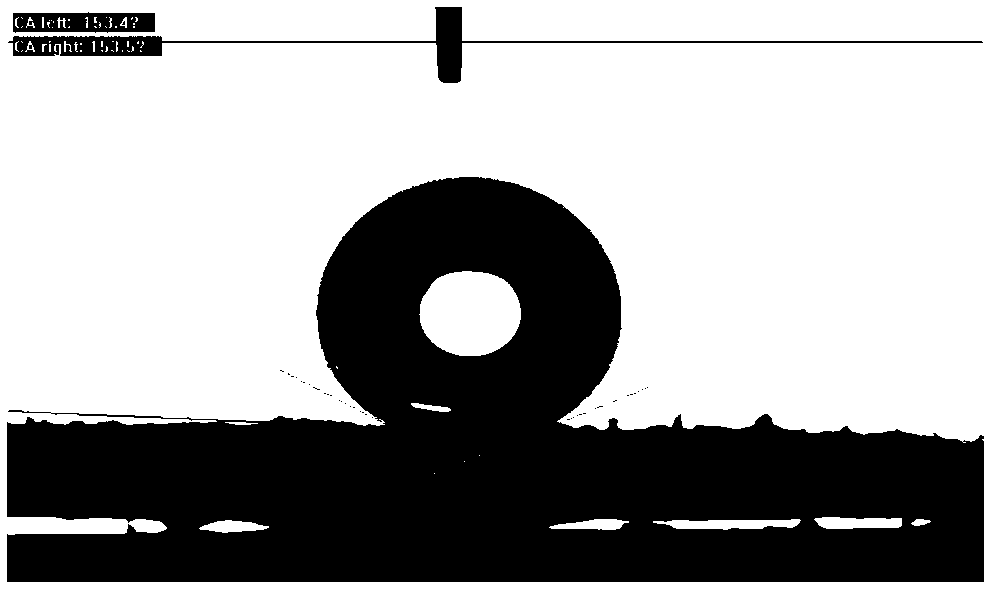

[0047] The superhydrophobic preservative wood in the present embodiment comprises wood matrix (being the masson pine wood chip), and the inside of this wood matrix is impregnated with nano-Cu 2 O particles, coated with a superhydrophobic coating. The above-mentioned super-hydrophobic coating is a vinyltriethoxysilane hydrolysis film layer. The preparation method of above-mentioned superhydrophobic preservative wood comprises the following steps:

[0048] (1) Dissolve 2g of copper acetate monohydrate in 100mL of water, stir magnetically for 15min with slight heating, then add 1.8g of D-glucose and 0.3g of K-30PVP under magnetic stirring, and continue stirring for 20min to obtain a mixed solution system;

[0049] (2) Take 70mL of the mixed solution system obtained in step (1) in the reactor liner, put masson pine wood chips at the same time, and then heat the reactor at 150°C for 7h;

[0050] (3) After the reaction kettle is lowered to room temperature, the wood chips are ta...

Embodiment 3

[0056] The superhydrophobic preservative wood in the present embodiment comprises wood matrix (being the masson pine wood chip), and the inside of this wood matrix is impregnated with nano-Cu 2 O particles, coated with a superhydrophobic coating. The above-mentioned super-hydrophobic coating is a vinyltriethoxysilane hydrolysis film layer. The preparation method of above-mentioned superhydrophobic preservative wood comprises the following steps:

[0057] (1) Dissolve 2g of copper acetate monohydrate in 100mL of water, stir magnetically for 15min with slight heating, then add 1.8g of D-glucose and 0.3g of K-30PVP under magnetic stirring, and continue stirring for 20min to obtain a mixed solution system;

[0058] (2) Take 70mL of the mixed solution system obtained in step (1) in the reactor liner, put masson pine wood chips at the same time, and then heat the reactor at 180°C for 8h;

[0059] (3) After the reaction kettle is lowered to room temperature, the wood chips are ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com