Technology and device for purifying and recycling polypropylene tail gas through pressure swing adsorption

A technology for recycling polypropylene and pressure swing adsorption, which is used in adsorption purification/separation, hydrocarbon purification/separation, hydrocarbons, etc. Separation rate, reduction of useless power consumption, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

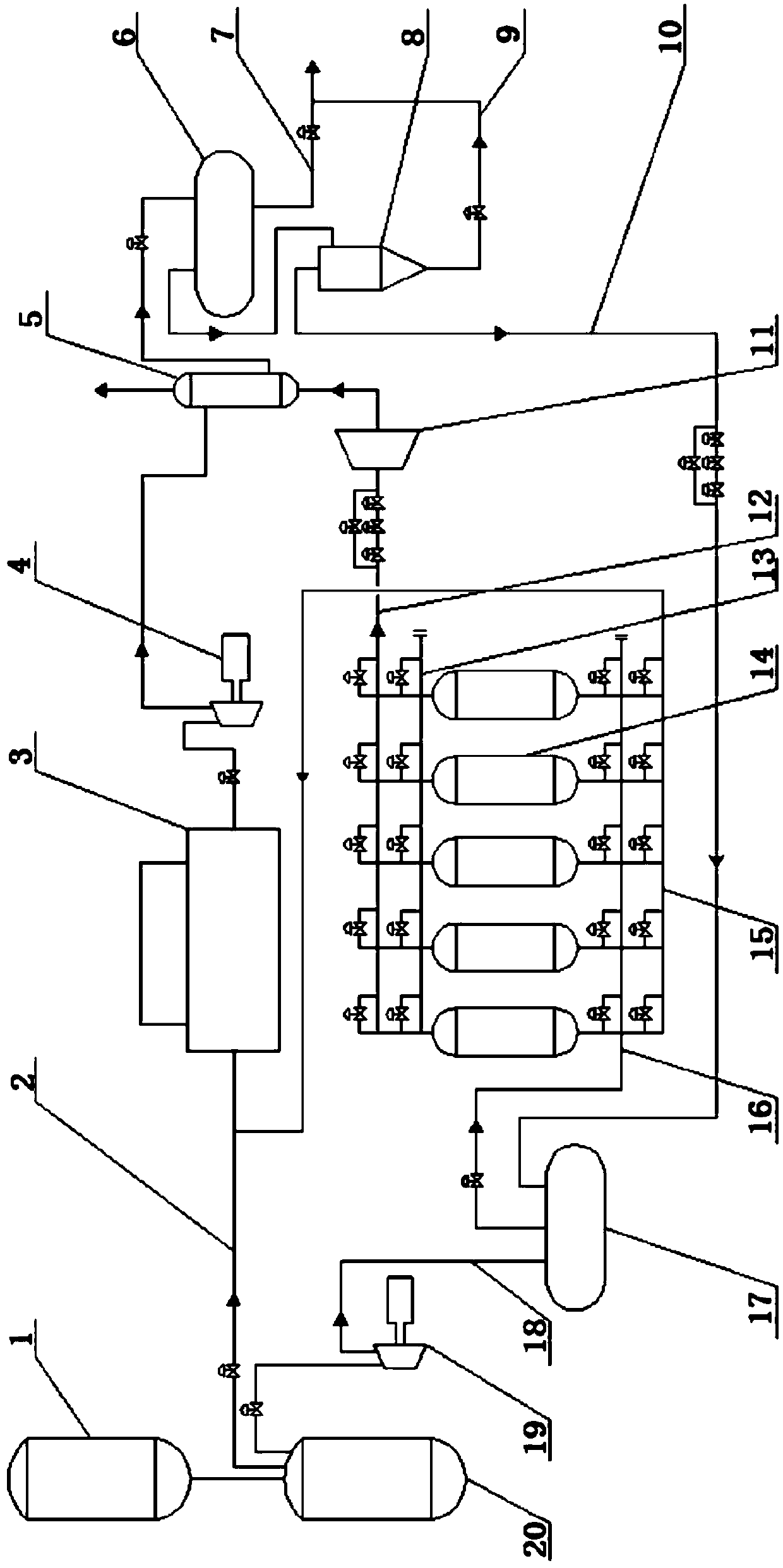

[0038] A device for purifying and recovering polypropylene tail gas by pressure swing adsorption of the present invention comprises a polymerization kettle 1, a flash kettle 20, a gas cabinet 3, a propylene condensation compressor 4, an adsorption tower 14, a heat exchanger 5, a liquefaction tank 6, and Including a vacuum booster 19, a surge tank 17, an expander 11, and a gas-liquid separation / 8; the polymerization kettle 1 is connected to a flash kettle 20, and the flash kettle 20 is connected to the inlet of the gas cabinet 3 through a low-pressure gas pipeline 2, The flash tank 20 is connected to the vacuum booster 19 and the buffer tank 17 in turn through the replacement gas pipeline 18; the bottom of the adsorption tower 14 is connected to the buffer tank 17 through the feed pipeline 16, and the bottom of the adsorption tower 14 is also connected to the gas cabinet through the reverse discharge pipeline 15. 3 is connected to the inlet, and the top of the adsorption tower 1...

Embodiment 2

[0052] A device for purifying and recovering polypropylene tail gas by pressure swing adsorption of the present invention comprises a polymerization kettle 1, a flash kettle 20, a gas cabinet 3, a propylene condensation compressor 4, an adsorption tower 14, a heat exchanger 5, a liquefaction tank 6, and Including a vacuum booster 19, a surge tank 17, an expander 11, and a gas-liquid separation / 8; the polymerization kettle 1 is connected to a flash kettle 20, and the flash kettle 20 is connected to the inlet of the gas cabinet 3 through a low-pressure gas pipeline 2, The flash tank 20 is connected to the vacuum booster 19 and the buffer tank 17 in turn through the replacement gas pipeline 18; the bottom of the adsorption tower 14 is connected to the buffer tank 17 through the feed pipeline 16, and the bottom of the adsorption tower 14 is also connected to the gas cabinet through the reverse discharge pipeline 15. 3 is connected to the inlet, and the top of the adsorption tower 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com