Surface modification method for polyolefin material

A surface modification, polyolefin technology, applied in the direction of fiber type, textile and papermaking, fiber processing, etc., can solve the problems of shortened grafting time, volatile solvent, easy loss of surface polarity, etc., to achieve uniform functionalization treatment, The effect of shortening the grafting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present embodiment provides a kind of method of polyolefin material surface modification, and it comprises the following steps:

[0031] (a) Immerse the commercially available polyethylene sheet in 10% sodium hypochlorite aqueous solution by mass content, add a small amount of sodium bicarbonate (0.5-1% of the solution mass content) to adjust the pH of the aqueous solution to be 5.5-6, at 30-40 Under the condition of ℃, carry out UV irradiation for 20min (UV wavelength is 280-400nm) to carry out chlorination treatment to obtain chlorinated polyolefin material (the surface chlorination degree of chlorinated polyolefin material is 30-50%);

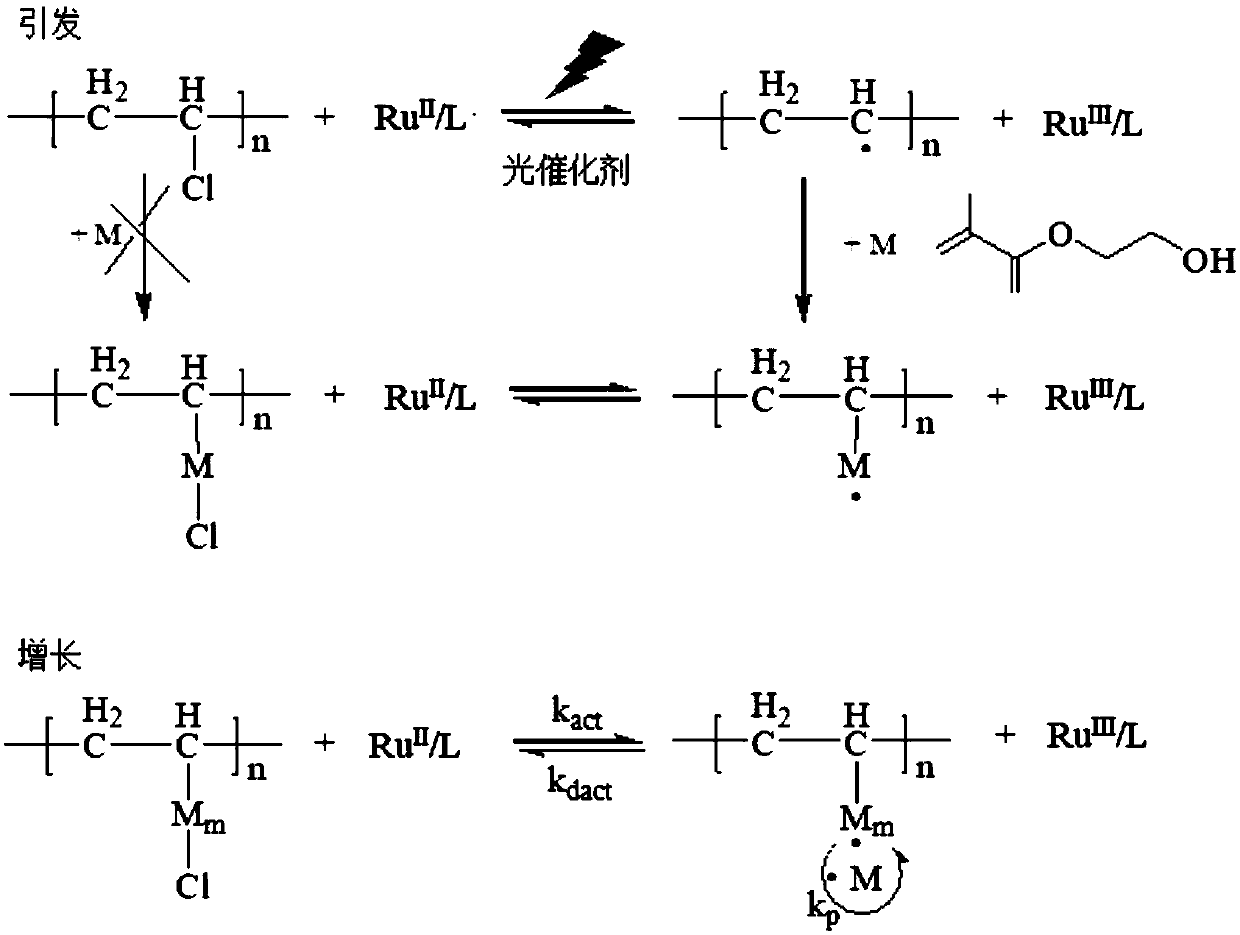

[0032] (b) Immerse the chlorinated polyolefin material (i.e., the surface chlorinated polyethylene sheet) in the grafting reaction solution to carry out photocatalytic-ATPR graft polymerization, and the grafting reaction solution contains: 100 parts of methyl Hydroxyethyl acrylate, 0.2 parts of pentamethyldiethyltriamine and 0.002...

Embodiment 2

[0034] The present embodiment provides a kind of method of polyolefin material surface modification, and it comprises the following steps:

[0035] (a) Immerse commercially available polypropylene biaxially stretched film in 5% sodium hypochlorite aqueous solution, add a small amount of sodium bicarbonate (0.5~1% of solution mass content) to be 5.5~6 to adjust the pH of aqueous solution, at 30~40 ℃ Carry out UV (same as in Example 1) illumination 10min under the condition of chlorination, to obtain chlorinated polyolefin material (the surface chlorination degree of chlorinated polyolefin material is 30~50%) to carry out chlorination;

[0036] (b) Immerse the chlorinated polyolefin material (i.e. the polypropylene biaxially stretched film after surface chlorination) in the grafting reaction solution to carry out photocatalytic-ATPR graft polymerization, and its grafting reaction aqueous solution contains: 100 parts Hydroxyethyl methacrylate, 0.1 part of pentamethyldiethyltriami...

Embodiment 3

[0038] The present embodiment provides a kind of method of polyolefin material surface modification, and it comprises the following steps:

[0039] (a) Immerse commercially available polyethylene-propylene copolymer film in 8% sodium hypochlorite aqueous solution, add a small amount of sodium bicarbonate (0.5~1% of solution mass content) to be 5.5~6 to adjust the pH of aqueous solution, at 30~40 ℃ Carry out UV (same as in embodiment 1) illumination 15min under the condition of chlorinating to obtain chlorinated polyolefin material (the surface chlorination degree of chlorinated polyolefin material is 30~50%) to carry out chlorination;

[0040] (b) Immerse the chlorinated polyolefin material (i.e., the surface chlorinated polyethylene-propylene copolymer film) in the grafting reaction solution to carry out photocatalytic-ATPR graft polymerization, and the grafting reaction aqueous solution contains: 100 parts Acrylamide, 0.2 parts of triethanolamine and 0.0015 parts of tricyano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com