A kind of narrow dispersion graft copolymerization ABS composition and preparation method thereof

A technology of graft polymer and composition, which is applied in the field of high-efficiency preparation of ABS composition and its narrowly dispersed graft copolymer, which can solve problems such as complex process, low conversion rate, and long grafting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

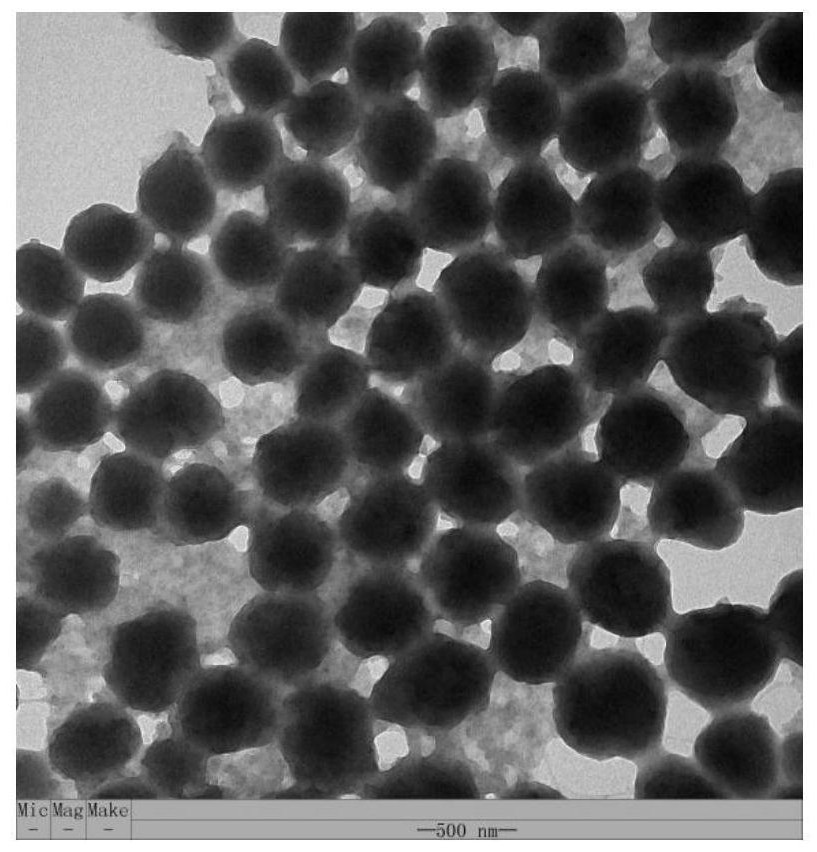

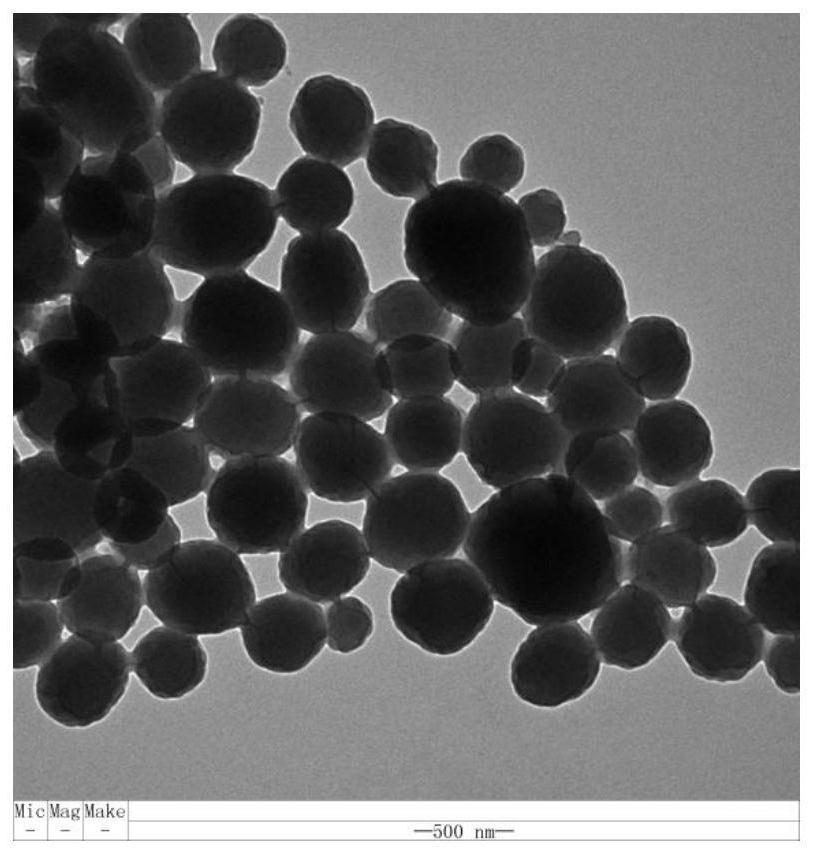

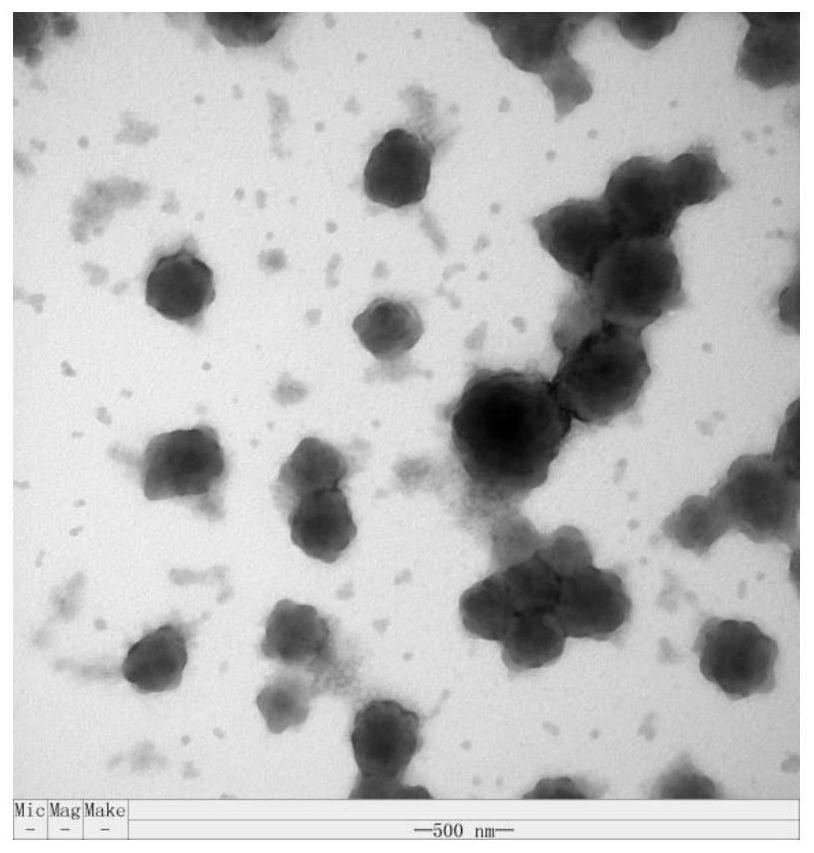

Image

Examples

Embodiment 1

[0032] Step 1: Preparation of ABS Grafted Polymer

[0033] (1.1) In parts by weight, add 0.4 part of emulsifier sodium lauryl sulfate, 22.5 parts of deionized water, styrene and acrylonitrile monomers to a total of 40 parts, the ratio of styrene to acrylonitrile is 2.5 / 1, and 0.12 parts are Cumene hydrogen oxide, shake to become a pre-emulsion;

[0034] (1.2) Weigh 0.04 part of sodium pyrophosphate, 0.1 part of fructose, 0.01 part of ferrous sulfate, 5 parts of deionized water, 0.04 part of cumene hydrogen peroxide, dissolve and mix and place 60 parts of dry polybutadiene In the latex, the pre-emulsion was then injected into the polybutadiene latex by dropwise feeding under nitrogen protection under the condition of controlling the reaction temperature at 57° C. and the rotating speed of 300 rpm, and the feeding time was 60 min, and the feeding was carried out by dropwise feeding at the same time. A potassium hydroxide solution with a mass concentration of 5% was injected, wh...

Embodiment 2

[0040] Step 1: Preparation of ABS Grafted Polymer

[0041] (1.1) In parts by weight, 0.6 part of emulsifier disproportionated potassium rosinate soap, 33.75 parts of deionized water, styrene and acrylonitrile monomers total 60 parts, the ratio of styrene to acrylonitrile is 2.5 / 1, 0.18 parts of peroxide Hydrogen cumene, shake to become a pre-emulsion;

[0042] (1.2) Weigh 0.06 part of sodium pyrophosphate, 0.15 part of fructose, 0.015 part of ferrous sulfate, 7.5 parts of deionized water, 0.06 part of cumene hydrogen peroxide, dissolve and mix and place 40 parts of dry polybutadiene In the latex, the pre-emulsion was injected into the polybutadiene latex by dropwise feeding under the conditions of controlling the reaction temperature at 57 ° C and the rotating speed at 300 rpm, and the feeding time was 60 min. % potassium hydroxide solution, wherein 0.225 parts of potassium hydroxide, 4.275 parts of deionized water, keep the pH of the reaction system between 9.4-9.7;

[0043...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com