Method for producing hydrogen gas through reinforcing anaerobic fermentation of surplus sludge

An anaerobic fermentation and excess sludge technology, applied in fermentation, biological sludge treatment, chemical instruments and methods, etc., can solve problems such as increasing the release of organic matter, improve the rate of hydrogen production, reduce environmental pollution, and alleviate energy shortages Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

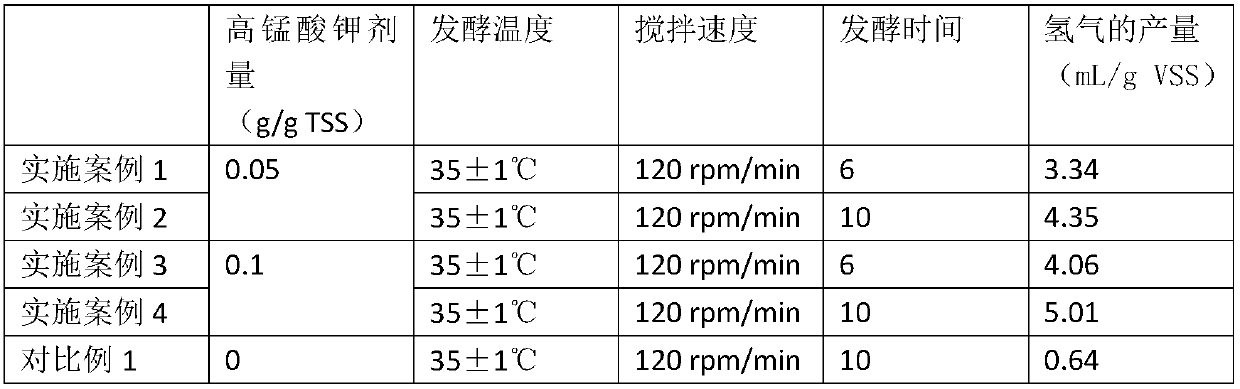

Embodiment example 1

[0022] (1) In a plexiglass container with a working volume of 4L, the sludge produced by the municipal sewage treatment plant is placed at 4°C to naturally settle for 1d, and the supernatant is removed to obtain the fermentation raw material.

[0023] (2) Add 500 mL of the sludge obtained in (1) into the reactor, and add 0.05 g / g TSS potassium permanganate, and stir evenly. Fill the reactor with nitrogen for 5 minutes to remove oxygen, seal the reactor and put it into a shaker for anaerobic fermentation, where the shaker fermentation temperature is 35±1℃, the shaking speed is 120rpm / min, and the fermentation time (ie, pollution) The residence time of the mud in the reactor) is 6 days, and the hydrogen production is 3.34 mL / g VSS.

Embodiment example 2

[0025] (1) In a plexiglass container with a working volume of 4L, the sludge produced by the municipal sewage treatment plant is placed at 4°C to naturally settle for 1d, and the supernatant is removed to obtain the fermentation raw material.

[0026] (2) Add 500 mL of the sludge obtained in (1) into the reactor, and add 0.05 g / g TSS potassium permanganate, and stir evenly. Fill the reactor with nitrogen for 5 minutes to remove oxygen, seal the reactor and put it into a shaker for anaerobic fermentation, where the shaker fermentation temperature is 35±1℃, the shaking speed is 120rpm / min, and the fermentation time (ie, pollution) The residence time of the mud in the reactor is 10 days, and the hydrogen production is 4.35 mL / g VSS.

Embodiment example 3

[0028] (1) In a plexiglass container with a working volume of 4L, the sludge produced by the municipal sewage treatment plant is placed at 4°C to naturally settle for 1d, and the supernatant is removed to obtain the fermentation raw material.

[0029] (2) Put 500mL of the sludge obtained in (1) into the reactor, and add 0.1g / g TSS potassium permanganate, stir evenly. Fill the reactor with nitrogen for 5 minutes to remove oxygen, seal the reactor and put it into a shaker for anaerobic fermentation, where the shaker fermentation temperature is 35±1℃, the shaking speed is 120rpm / min, and the fermentation time (ie, pollution) The residence time of the mud in the reactor) is 6 days, and the hydrogen production is 4.06 mL / g VSS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com