Hydrocarbon fuel ignition type zero nitrogen rotor machine with oxygen as oxidant and control method thereof

A hydrocarbon fuel, zero nitrogen rotor technology, applied in fuel injection control, electrical control, engine control and other directions, can solve the problems of easy knocking, reduced combustion stability, unfavorable rapid heat release, etc., to achieve zero nitrogen emissions , the effect of improving the emission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

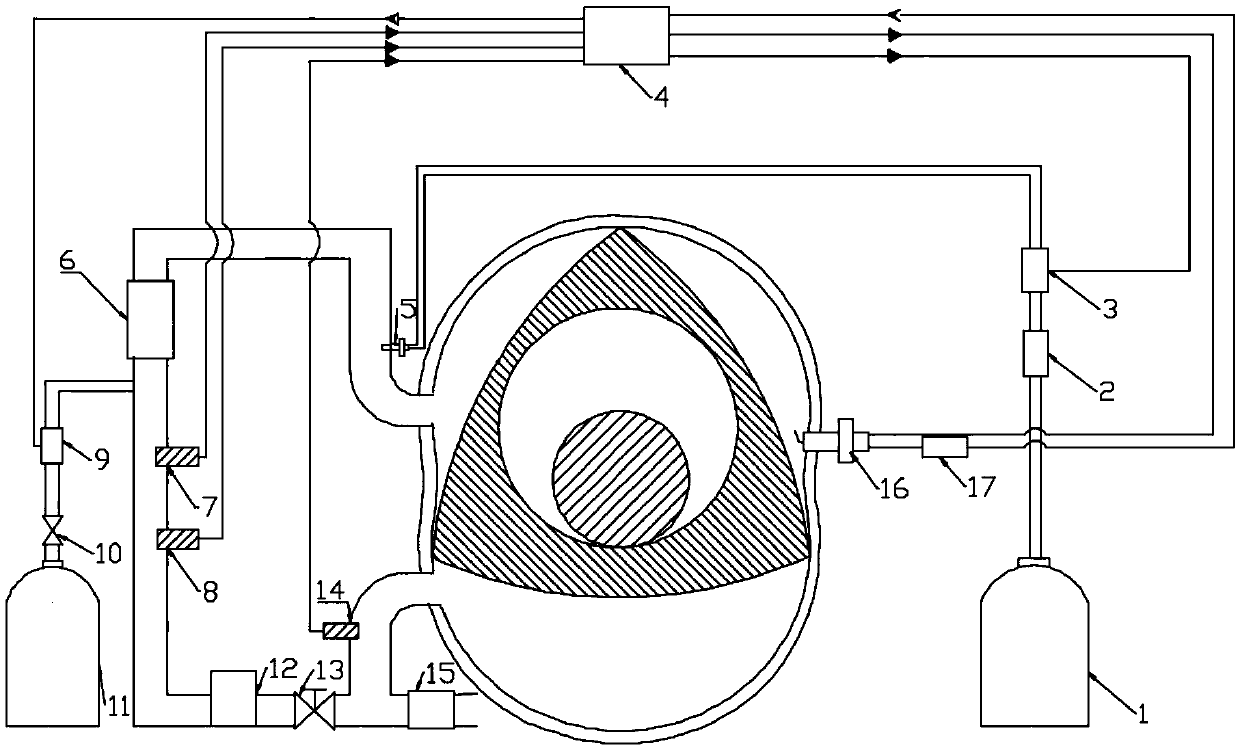

[0019] Such as figure 1 Including: a hydrocarbon fuel storage tank (1), the outlet of the storage tank is connected in series with the oil pump (2), the fuel flow meter (3), and the fuel nozzle (5) installed on the intake passage, and the CO Concentration sensor (14), exhaust gas circulation valve (13), condenser (12), temperature sensor (8), oxygen concentration sensor (7), pressure-stabilizing mixing tank (6), oxygen comes out of the oxygen storage tank (11) After passing through the oxygen pipeline pressure reducing valve (10) and the oxygen flow regulator (9) successively, it is mixed with the circulating exhaust gas and passed through the pressure-stabilizing mixing tank (6) and then enters the combustion chamber through the air inlet. The gas flow rate is also installed on the exhaust pipe regulator (15). ECU (4) controls engine ignition thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com