Irregular alloy billet heating device and heating method thereof

A heating device, induction heating device technology, applied in the direction of induction heating device, electric heating device, coil device, etc., can solve the problems of slow heating speed, large power consumption, heavy environmental pollution, etc., achieve rapid and uniform heating, prevent grain growth Larger and coarser effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

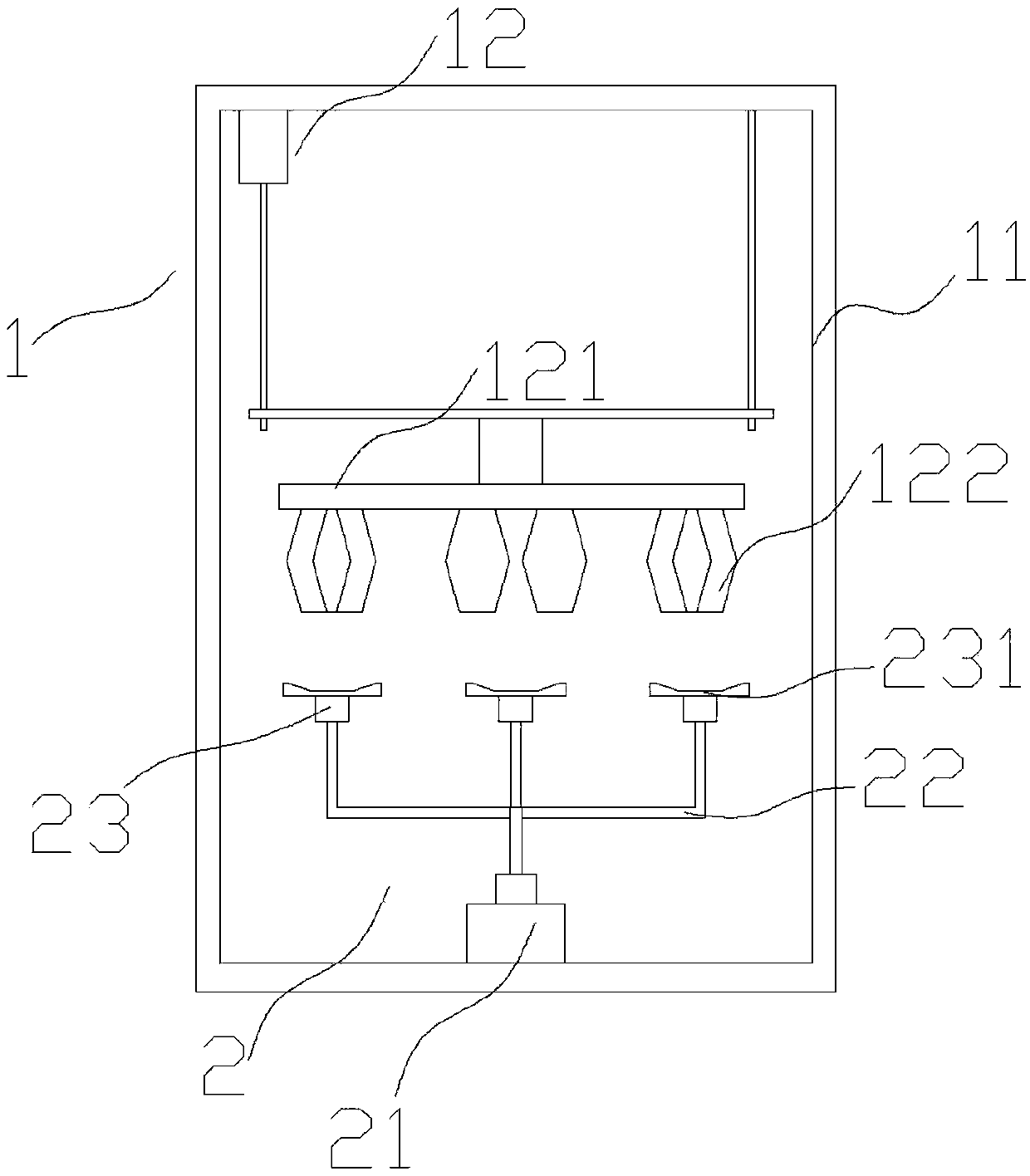

[0038] Such as Figure 1-3 As shown, a heating device for an irregular alloy billet includes:

[0039]Induction heating device 1, used for heating the irregular alloy blank;

[0040] Induction heating power supply, connected to the induction heating device 1 to supply power to the induction heating device 1;

[0041] The alloy billet rotating device 2 is used as a placement platform for the irregular alloy billet and is located below the induction heating device 1;

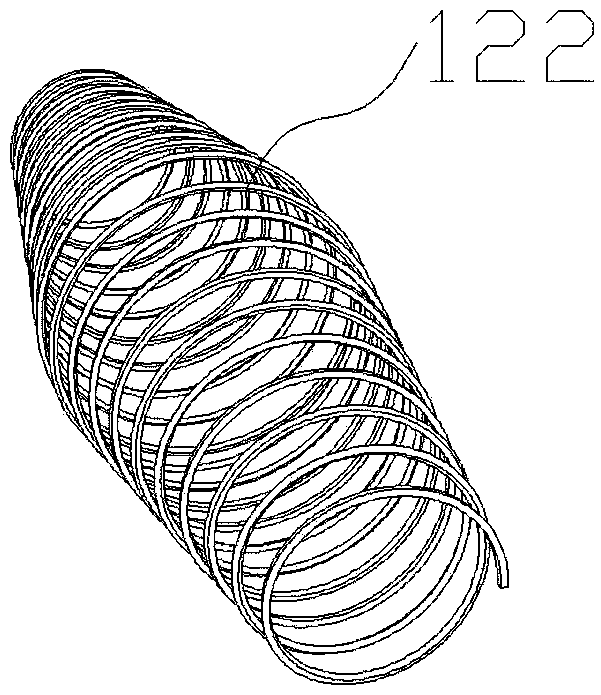

[0042] The induction heating device 1 includes a device frame body 11, a lifting device 12 fixed on the device frame body 11, a heating platform 121 fixedly installed on the lifting end of the lifting device 12, and a heating platform 121 fixedly installed on the heating platform 121. The induction heating unit 122, wherein the induction heating unit 122 is composed of an induction coil, the induction heating supply power is connected to the induction coil, and the induction coil is spindle-shaped.

[0043] In ...

Embodiment 2

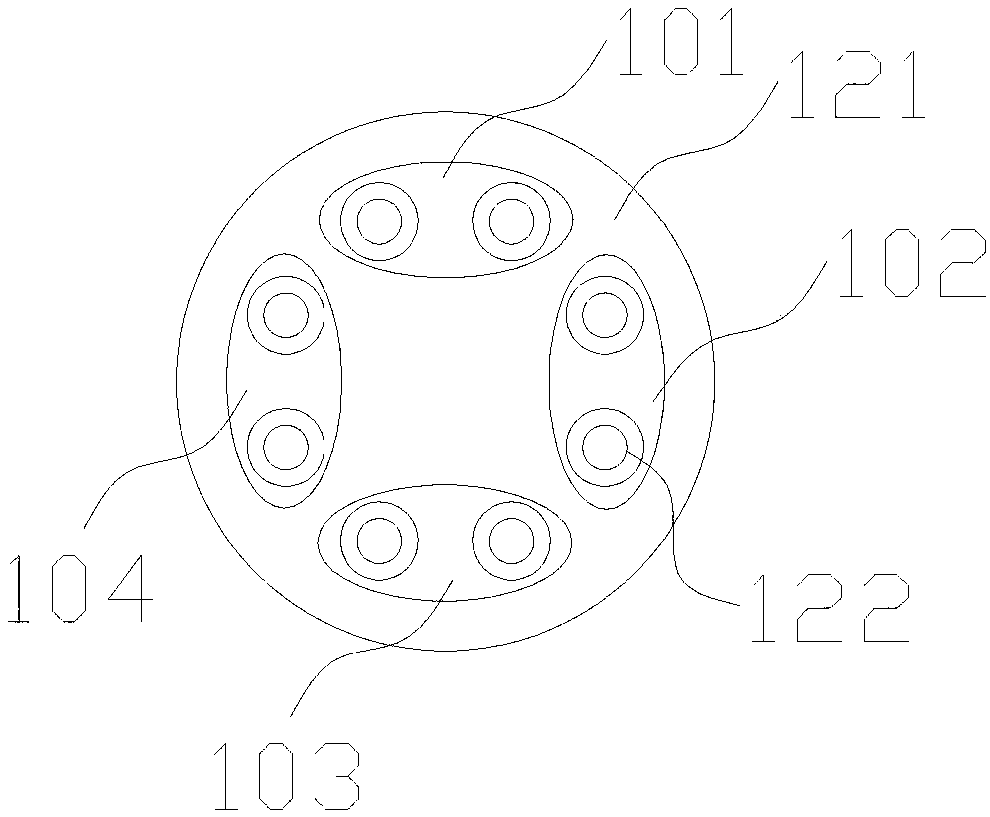

[0064] Such as Figure 4-5 As shown, there are 10 induction heating units 122, and the 10 induction heating units 122 are arranged on the heating platform 121, wherein the first to third induction heating units 122 form the first The induction heating device 101, the induction heating unit 122 of the 4th-6th constitutes the second induction heating device 102, the induction heating unit 122 of the 7th-8th constitutes the third induction heating device 103, and the induction heating unit 122 of the 9th- Ten induction heating units 122 form the fourth induction heating device 104, the induction coil of the first induction heating device 101 has 18 turns, and the induction coil of the second induction heating device 102 has 12 turns. The induction coil of the third induction heating device 103 has 10 turns, and the induction coil of the fourth induction heating device 104 has 8 turns.

[0065] 12 said alloy billet rotation devices 23 and 12 said alloy billet placement discs 231 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power supply | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com