Meat-like food rich in soybean polypeptide and processing method thereof

A soybean polypeptide and meat imitation technology, which is applied to the imitation meat food rich in soybean polypeptide and its processing field, can solve problems such as harm to human health, and achieve the effects of being beneficial to health, easy to absorb, and promoting fat metabolism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

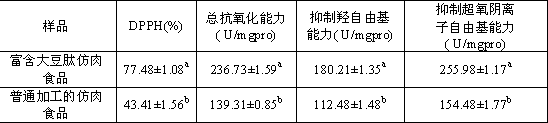

Examples

Embodiment 1

[0022] The soybean meal is coarsely sieved to remove dust, gravel and other sundries; then the raw material of the soybean meal is ground and crushed, and passed through an 80-mesh sieve to obtain soybean meal powder; 3500g of soybean meal powder, 2500g of water, 100g of starch, and 1000g of soybean protein are mixed; The amount of g raw protein added to add alkaline protease Alcalase (enzyme activity is 2 × 10 4 U / g) 137 grams, after mixing evenly, carry out ultrasonic enzymolysis, the ultrasonic conditions are: ultrasonic power 500W, ultrasonic time 12min, ultrasonic temperature 45°C; add 50g of salt and 100g of edible oil, and mix well again; The material speed is 100r / min, the extrusion temperature is 120°C, and the screw speed is 180r / min. The twin-screw extrusion extruder is used for extruding and puffing. Finally, the extruded and puffed product is dried in a fluidized bed until the moisture content is 8%. , vacuum packaging.

Embodiment 2

[0024] The soybean meal is coarsely sieved to remove dust, gravel and other sundries; then the soybean meal raw material is ground and crushed, and passed through an 80-mesh sieve to obtain soybean meal powder; 3900g of soybean meal powder, 2900g of water, 140g of starch, and 1200g of soybean protein are mixed; The amount of g raw protein added to add alkaline protease Alcalase (enzyme activity is 2 × 10 4 U / g) 195 grams, after mixing evenly, carry out ultrasonic enzymolysis. The material speed is 110r / min, the extrusion temperature is 130°C, and the screw speed is 190r / min. The twin-screw extrusion extruder is used for extruding and puffing. Finally, the extruded and puffed product is dried in a fluidized bed to a moisture content of 9%. , vacuum packaging.

Embodiment 3

[0026] The soybean meal is coarsely sieved to remove dust, gravel and other sundries; then the soybean meal raw material is ground and crushed, and passed through a 100-mesh sieve to obtain soybean meal powder; 4200g of soybean meal powder, 3500g of water, 300g of starch, and 1500g of soybean protein are mixed; The amount of g raw protein added to add alkaline protease Alcalase (enzyme activity is 2 × 10 4 U / g) 278 grams, after mixing evenly, perform ultrasonic enzymolysis, the ultrasonic conditions are: ultrasonic power 750W, ultrasonic time 15min, ultrasonic temperature 40°C; add 70g of salt and 150g of edible oil, and mix well again; The material speed is 120r / min, the extrusion temperature is 135°C, and the screw speed is 195r / min. The twin-screw extrusion extruder is used for extruding and puffing. Finally, the extruded and puffed product is dried in a fluidized bed until the moisture content is 10%. , vacuum packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com