Reverse osmosis membrane, preparation method and applications thereof

A reverse osmosis membrane and support layer technology, applied in the field of separation membranes, can solve the problems of poor pollution resistance of reverse osmosis membranes, and achieve the effects of improving anti-pollution ability, hydrophilicity, and salt interception rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

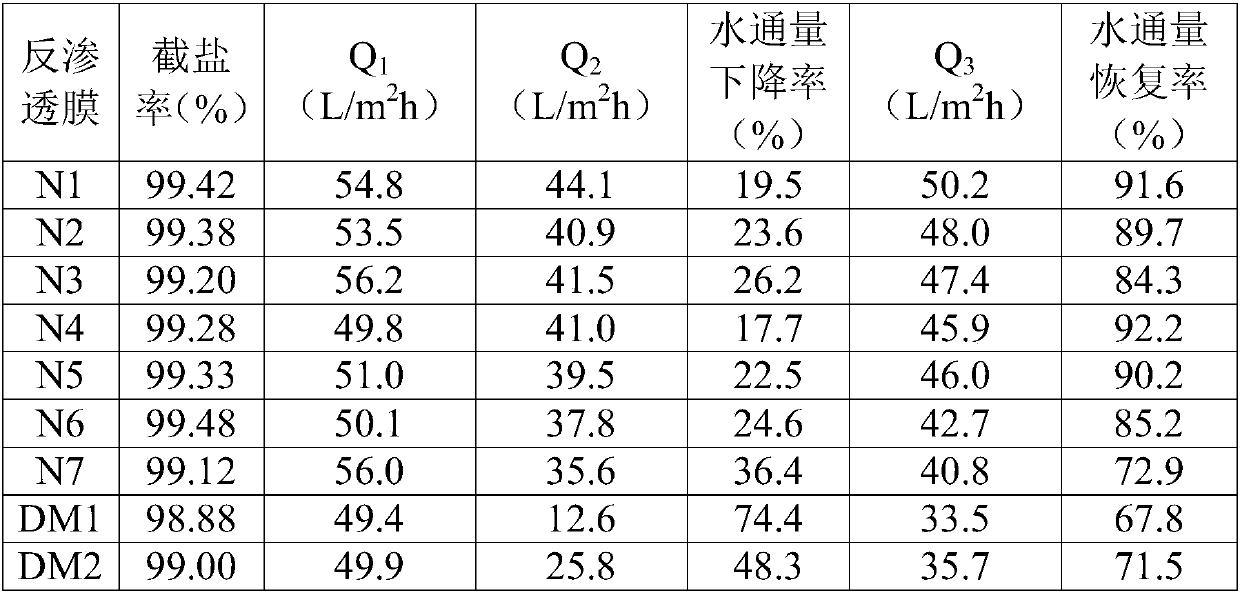

Examples

preparation example Construction

[0041] The present invention also provides a method for preparing the above-mentioned reverse osmosis membrane, the method comprising: in the presence of a curing accelerator, contacting the support layer with polyamines, ammonium salts containing epoxy groups, and polyacyl chlorides for interfacial polymerization to form a separation layer , and make the epoxy group in the ammonium salt containing epoxy group cross-linking reaction with polyamide.

[0042] Through the preparation method of the present invention, while forming the separation layer, the polyamide of the separation layer can be cross-linked with the epoxy group in the ammonium salt containing epoxy groups to finally form a modified separation layer.

[0043]According to a preferred embodiment of the present invention, the steps of the interfacial polymerization and the crosslinking reaction include: first mixing the support layer with an aqueous phase containing polyamines, ammonium salts containing epoxy groups,...

Embodiment 1

[0081] This example is used to illustrate the reverse osmosis membrane provided by the present invention and its preparation method.

[0082] The upper surface of the polysulfone porous membrane (the surface of the polysulfone layer, the same below) was contacted with an aqueous solution containing 2% by weight of m-phenylenediamine, 1% by weight of 2,3-epoxypropyltrimethylammonium chloride and 0.1% by weight 2,4,6-tris(dimethylaminomethyl)phenol, drained after contacting at 25°C for 10s; then, the upper surface of the polysulfone porous membrane was contacted with an Isopar E solution containing 0.1% by weight of trimesoyl chloride, Drain after contacting at 25°C for 10s; then, put the membrane into an oven and heat at 70°C for 5 minutes to obtain a composite reverse osmosis membrane M1, in which the thickness of the separation layer is 115nm.

Embodiment 2

[0084] This example is used to illustrate the composite reverse osmosis membrane provided by the present invention and its preparation method.

[0085] The upper surface of the polysulfone porous membrane was contacted with an aqueous solution containing 2% by weight of m-phenylenediamine, 5% by weight of 2,3-epoxypropyltriethylammonium chloride and 0.5% by weight of 2,4,6-tri( Dimethylaminomethyl) phenol, after contacting for 10s at 25°C, discharge; then, contact the upper surface of the polysulfone porous membrane with an Isopar E solution containing 0.1% by weight of trimesoyl chloride, and discharge after contacting for 10s at 25°C; Then, the membrane was put into an oven and heated at 100° C. for 3 minutes to obtain a composite reverse osmosis membrane M2, wherein the thickness of the separation layer was 118 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com