Multi-stage rapid conversion gas protection device for argon arc welding of elbow parts

A gas shielding device and argon arc welding technology, which is applied to the device for supplying/removing shielding gas, welding accessories, etc. Reduce tooling costs, reliable protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

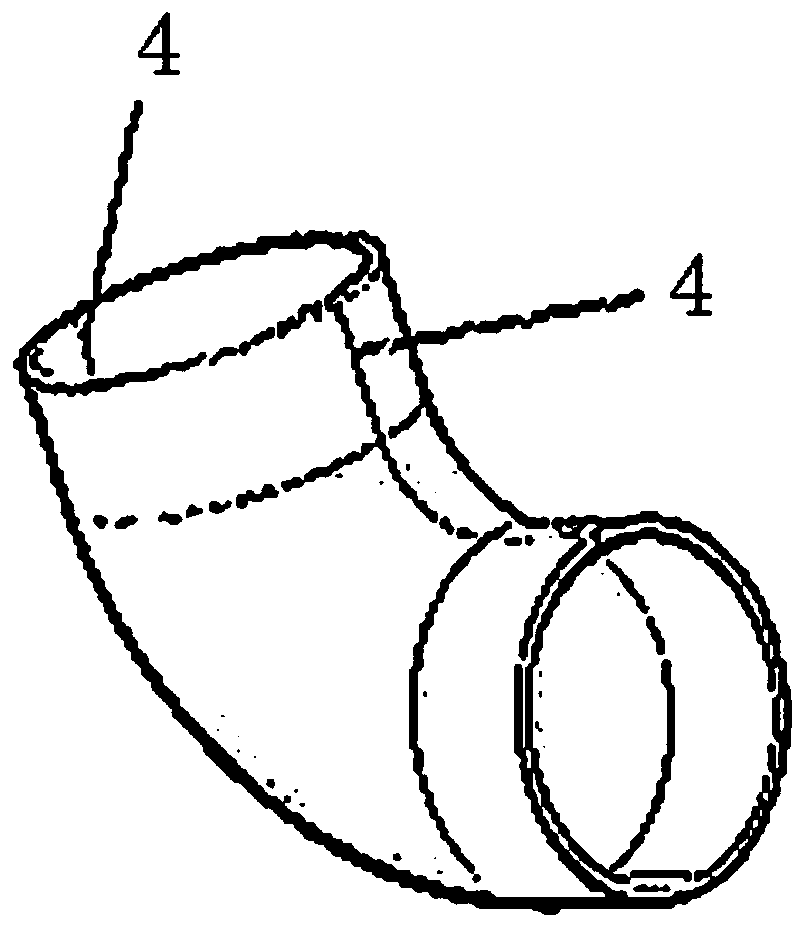

[0025] Such as figure 1 As shown, the welding seam processing of typical elbow butt welding parts is difficult, and such parts have high requirements on welding quality.

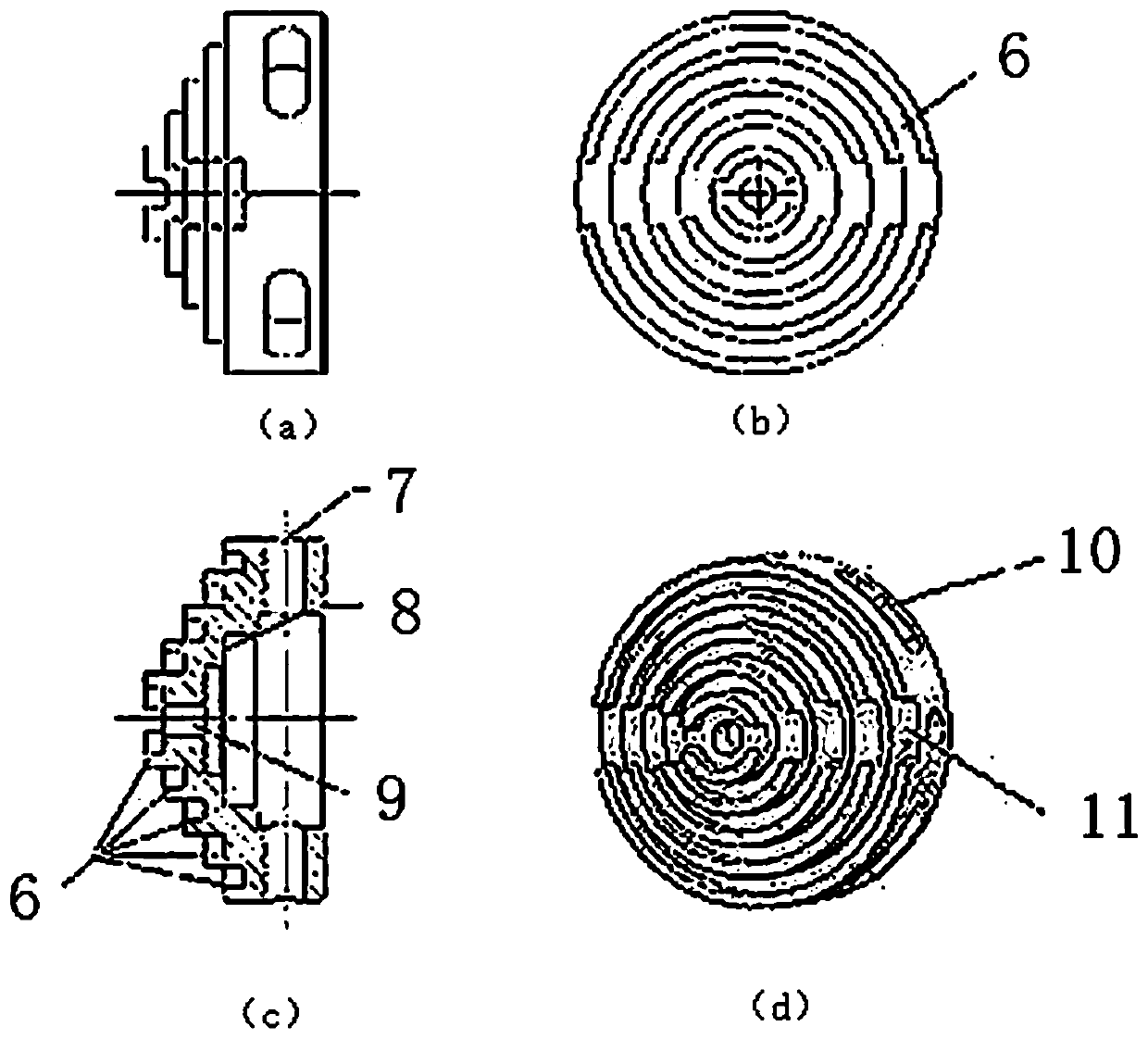

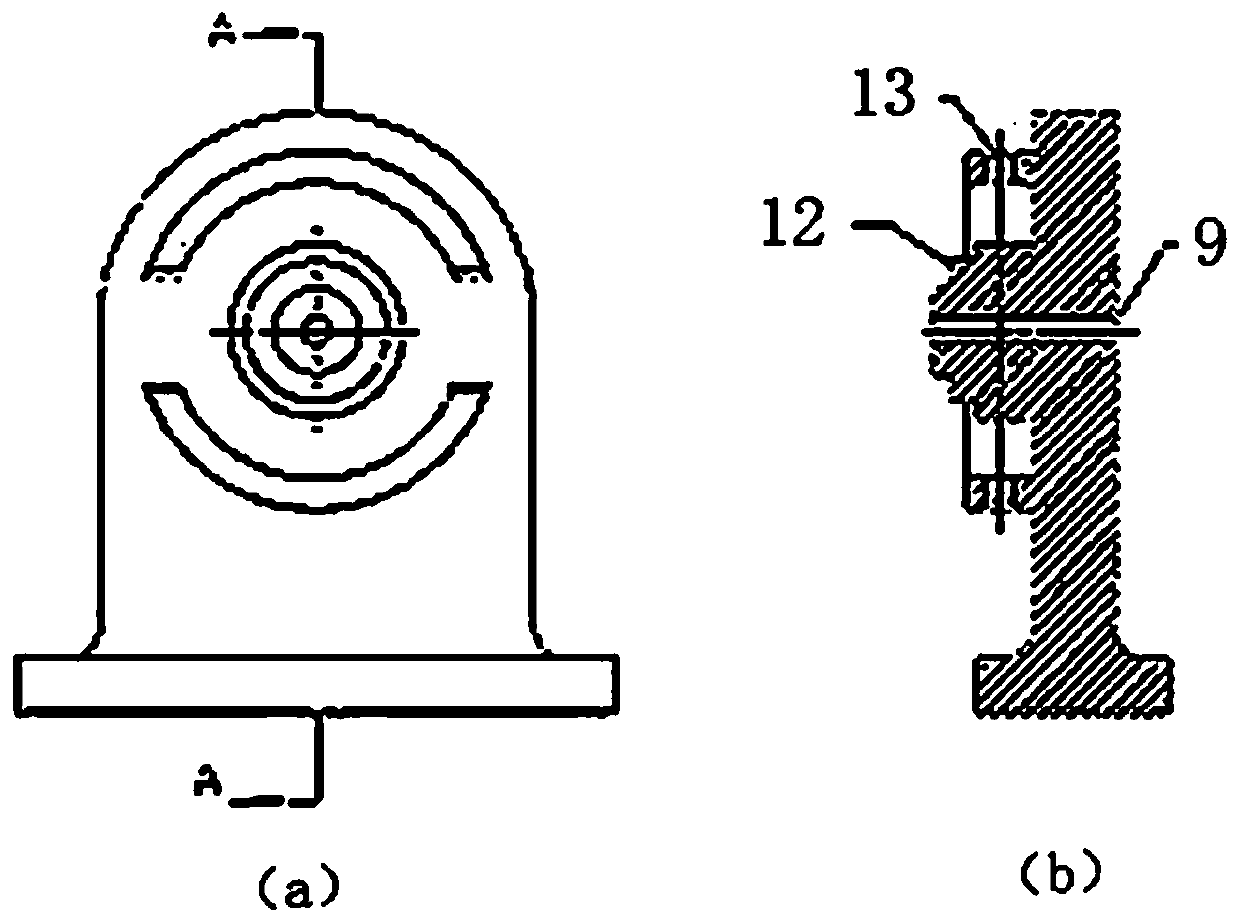

[0026] see figure 2 (a), figure 2 (b), figure 2 (c), figure 2 (d) and image 3 (a), image 3 (b), the side of the mounting seat 1 of the present invention is processed with a flange, and the plug 2 is arranged inside the flange. The step groove 8 matched with the platform 12; the upper and lower sides of the flange are oppositely provided with a positioning threaded hole 13, the plug 2 is opposite to the positioning threaded hole 13 and a bolt hole 7 is provided, and the positioning bolt 3 is installed through the positioning threaded hole 13, and the positioning bolt 3 Pass through the bolt hole 7 and tighten on the boss surface of the mounting seat. The plug 2 runs through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com