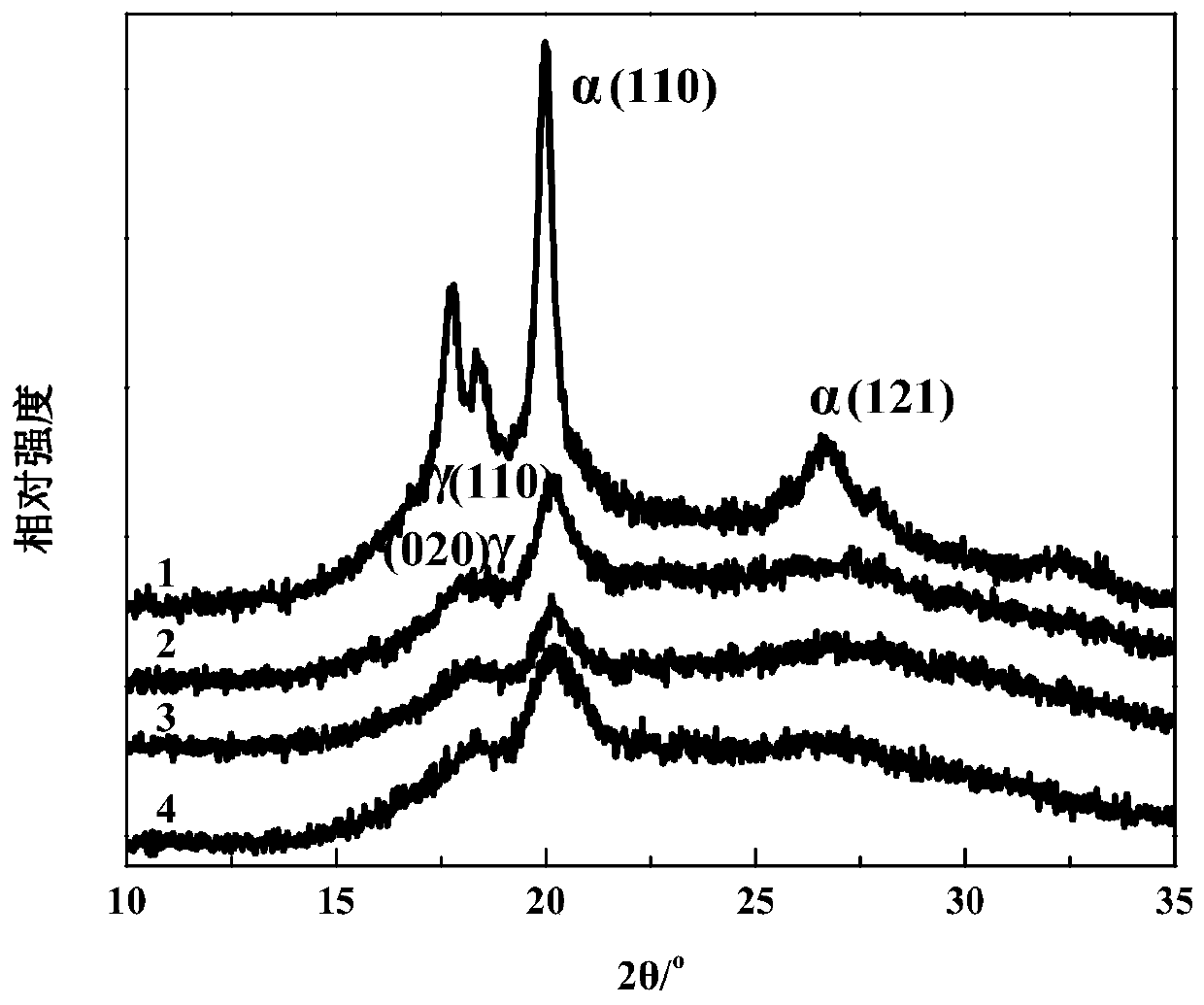

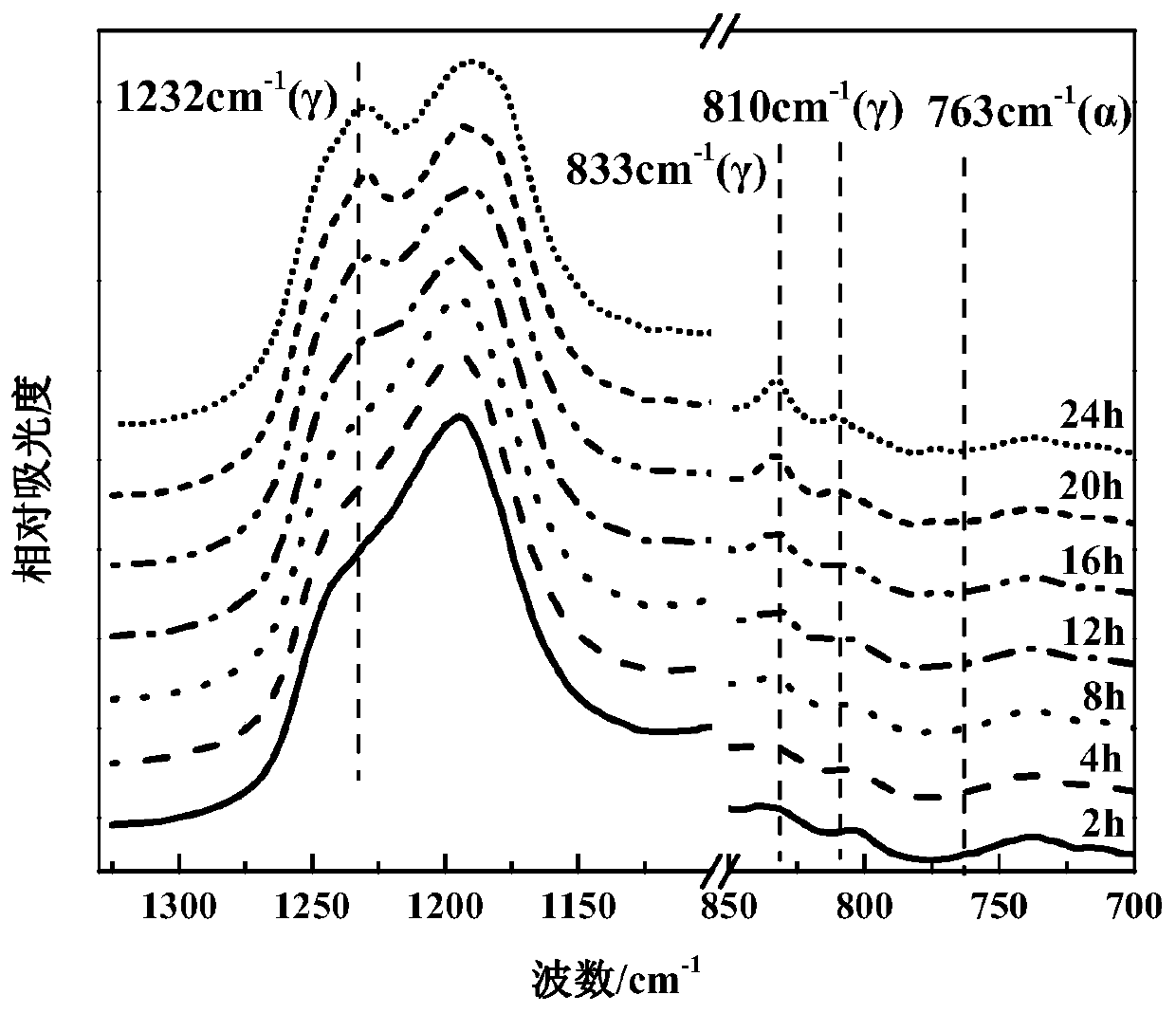

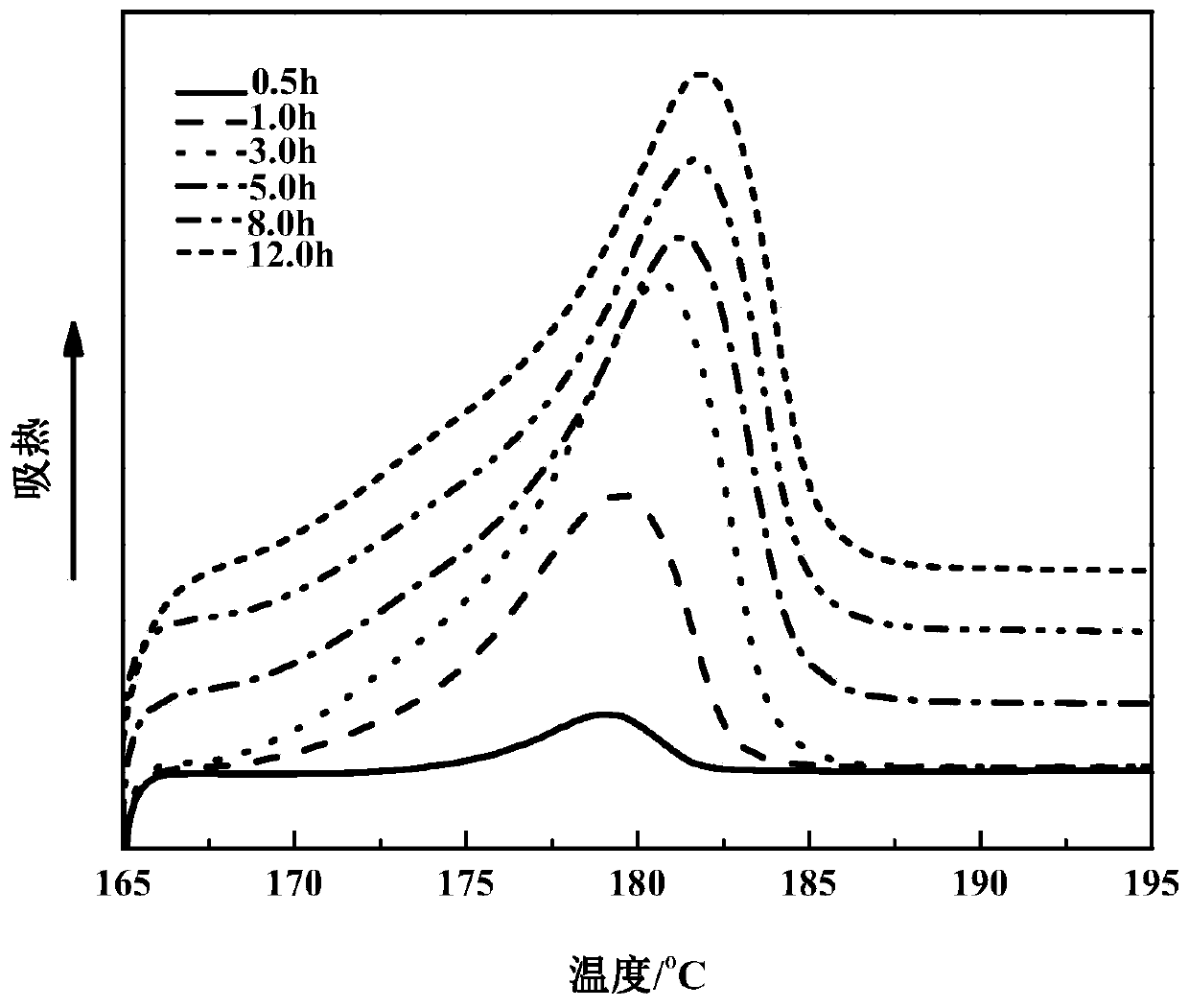

Preparation method of 100% gamma phase PVDF (polyvinylidene fluoride) film

A thin film, illite technology, applied in the field of materials, can solve the problems of slow crystal growth rate, harsh conditions, unfavorable promotion and application, etc., and achieve the effect of fast crystallization rate and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] 1. Preparation method of organically modified illite

[0047] First, the illite is subjected to ultrasonic treatment, and then placed on an electromagnetic stirrer at a certain temperature to stir, and then a dilute hydrochloric acid solution and a certain mass fraction of cationic surfactant are slowly added, stirred for a certain period of time, and left to activate to complete the reaction. The suspension is vacuum-filtered. During the suction-filtration process, the unreacted ions are removed by alternating washing with deionized water and absolute ethanol several times, dried in a vacuum oven, and the modified silicate clay is ground, sieved, and bottled. The organically modified illite prepared by the present invention preferably has a stirring temperature of 60-100° C., and the preferred cationic surfactant is hexadecyltrimethylammonium bromide, octadecyltrimethylammonium bromide, didecyltrimethylammonium bromide, and didecyltrimethylammonium bromide. Dialkyldime...

Embodiment 1

[0054] The first step is to prepare modified illite with cetyltrimethylammonium bromide (CTAB). Add 10 g of illite to 150 mL of deionized water, sonicate for 2 h, and then stir on an 80° C. in the liquid. The mixed solution was electromagnetically stirred at 80° C. for 2 h, and left standing for 24 h to fully activate the reaction. The suspension was vacuum-filtered and washed three times alternately with deionized water and absolute ethanol to ensure the removal of CTAB free on the illite surface. Then it was dried in a vacuum oven at 70°C for 24 hours, taken out, and the dried organically modified illite was ground, sieved and bottled.

[0055] The second step is solution blending to prepare PVDF film containing 2.0wt% organic illite. Weigh 6mg of organic illite in dimethylacetamide (DMAc) in 30mL, ultrasonically disperse for 2h, weigh 294mg of PVDF pellets and add them to the conical flask, the concentration of the blended solution is 10mg / mL, and electromagnetically sti...

Embodiment 2

[0059] The first step is to prepare illite modified by octadecyltrimethylammonium bromide (STAB). Add 10g of illite to 150mL of deionized water, sonicate for 2h, and then stir on a 60°C electromagnetic stirrer. During the stirring process, slowly add 4mL (0.1mol / L) dilute hydrochloric acid solution and 3wt% CTAB to the clay suspension in the liquid. The mixed solution was electromagnetically stirred at 60° C. for 2 h, and left standing for 24 h to fully activate the reaction. The suspension was vacuum-filtered and washed three times alternately with deionized water and absolute ethanol to ensure the removal of STAB free on the illite surface. Then it was dried in a vacuum oven at 60°C for 24 hours, taken out, and the dried organically modified illite was ground, sieved and bottled.

[0060] The second step is solution blending to prepare PVDF film containing 0.1wt% organic illite. Weigh 0.25mg of organic illite in 50mL N,N-dimethylformamide (DMF), ultrasonically disperse fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com