Alkylation oil dechlorination method

A technology of alkylation oil and alkylation, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrotreating process, etc. It can solve the problems of high investment and operating costs, failure of hydrodechlorination products to meet quality indicators, and process flow Complicated problems, to achieve the effect of recycling, avoiding the stable period of unqualified products, and improving the removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

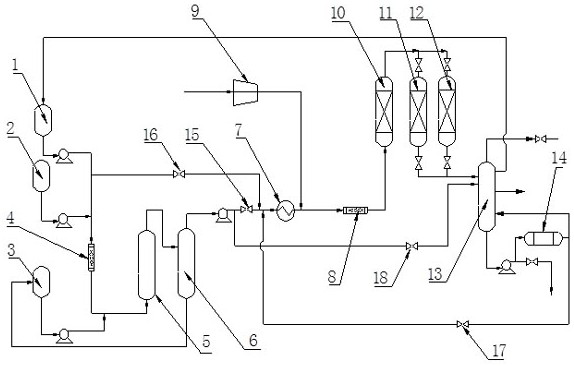

Embodiment 1

[0048] According to the scheme of the present invention, a new alkylation unit is built. After the alkylation reaction is completed, the ionic liquid is separated by the settling tank 6, and then the feed pump, the heat exchanger 7 and the hydrogen are fully mixed and dissolved in the SX type static mixer, and then enter the hydrodechlorination reactor 10. The reaction conditions For: reaction pressure 1.5MPa﹑liquid hour volume space velocity 3.8h -1 , The reaction temperature is 143°C. After the reaction is over, it enters the first adsorption dechlorination device 11 to absorb and remove inorganic chlorides. The first adsorption dechlorination device 11 or the second adsorption dechlorination device 12 can be filled with a conventional industrial dechlorination agent, and its main component includes calcium oxide. The adsorption temperature of the adsorption dechlorination device is 142°C, and the adsorption pressure is 1.4 MPa. Then the dechlorinated product enters the r...

Embodiment 2

[0052] According to the scheme of the present invention, a new alkylation unit is built. After the alkylation reaction is completed, the ionic liquid is separated by the settling tank 6, and then the feed pump, the heat exchanger 7 and the hydrogen are fully mixed and dissolved in the SX type static mixer, and then enter the hydrodechlorination reactor 10. The reaction conditions For: reaction pressure 1.6MPa﹑volume space velocity 4.2h -1 , The reaction temperature is 157°C. After the reaction is over, it enters the first adsorption dechlorination device 11 to absorb and remove inorganic chlorides. The first adsorption dechlorination device 11 or the second adsorption dechlorination device 12 can be filled with a conventional industrial dechlorination agent, and its main components include calcium oxide, magnesium oxide and the like. The adsorption temperature of the adsorption dechlorination device is 156°C, and the adsorption pressure is 1.5 MPa. Then the dechlorinated pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com