Image forming method of planographic printing component

A technology of lithography and imaging methods, applied in printing, printing process, printing plates, etc., can solve the problem of imaging ablation weakening the top layer, etc., and achieve the effects of reducing electrostatic source defects, reducing capacitance, and reducing voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

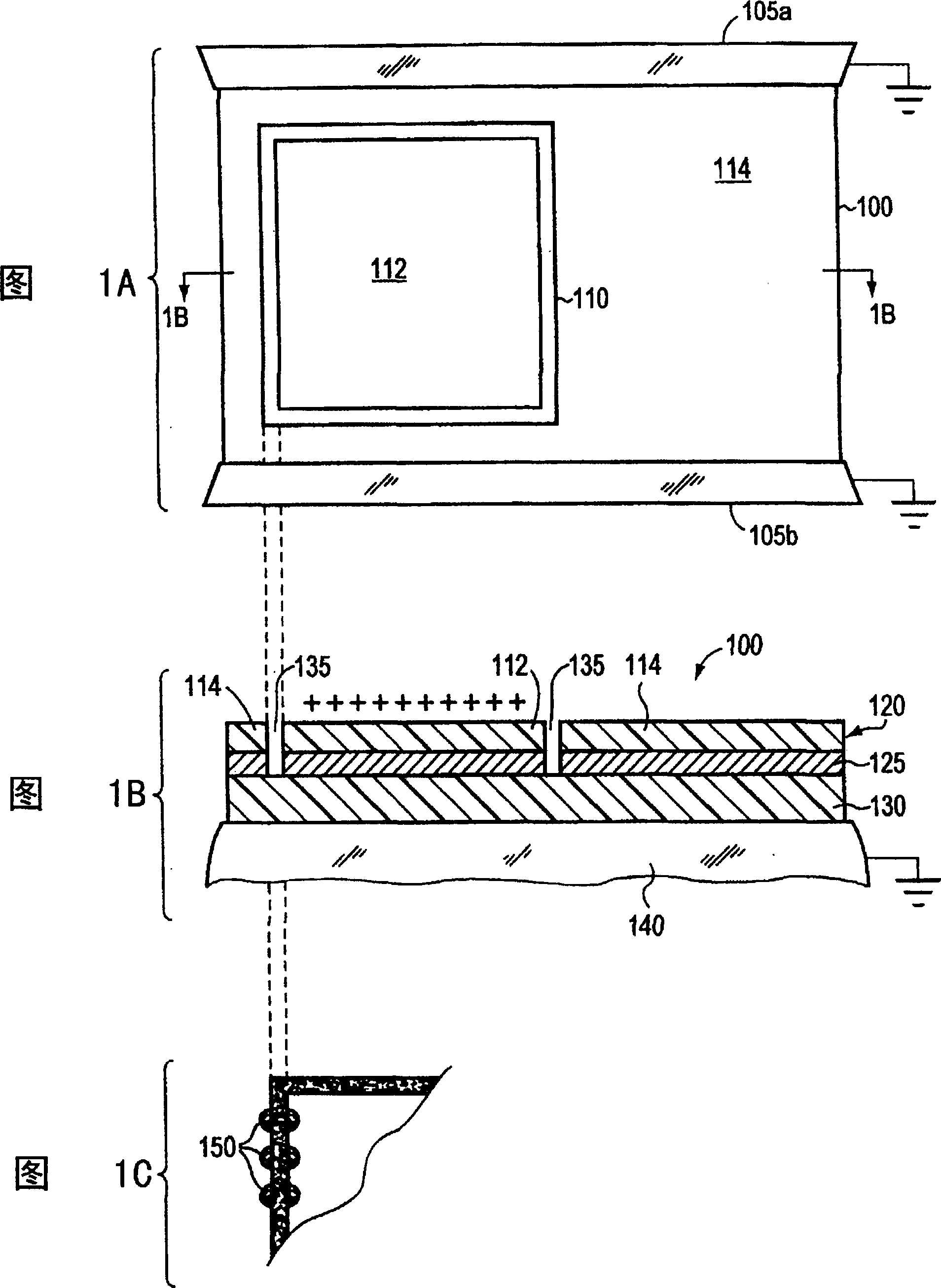

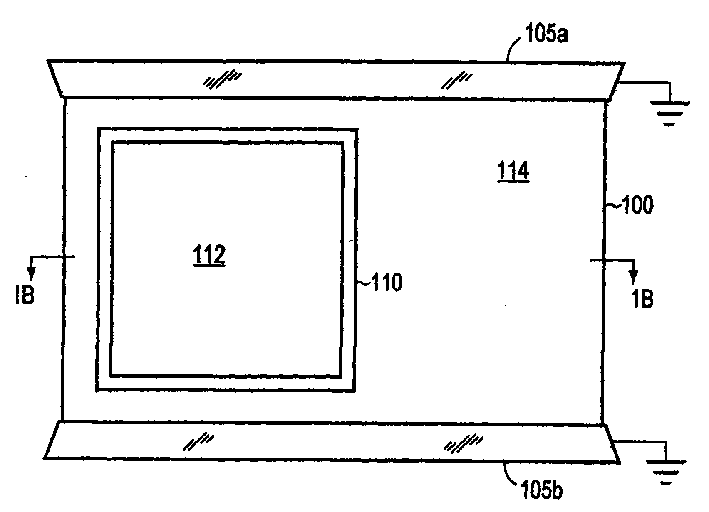

[0016] Figure 1 shows a pair of end splints 105 a 、105 b A printing plate 100 secured to a plate cylinder of a printing press or lithographic unit. The end clamps 105 are grounded through a mechanical connection to the machine frame. The printing plate 100 is ablated and imaged using an imaging apparatus such as that disclosed in the aforementioned US 5,339,737, Re 35,512, and US 5,822,345 (the entire disclosures of these patents are incorporated herein by reference). Applicable imaging devices include at least one laser device in the region of maximum plate response, i.e. at its lambda max Approximately close to the wavelength region where the printing plate absorbs the strongest emission.

[0017] Suitable imaging structures are also specified in US 5,339,737 and Re 35,512 and US 5,822,345. Briefly, the laser output can be provided directly to the surface of the printing plate via a lens or other beam directing component, or transmitted from a remote laser to the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com