Mode-spot converter and making method thereof

A mode spot converter and converter technology, applied in the field of integrated photonics, can solve problems such as increasing process complexity and increasing processing cost, and achieves the effects of being compatible with CMOS technology, low processing and manufacturing cost, and low insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

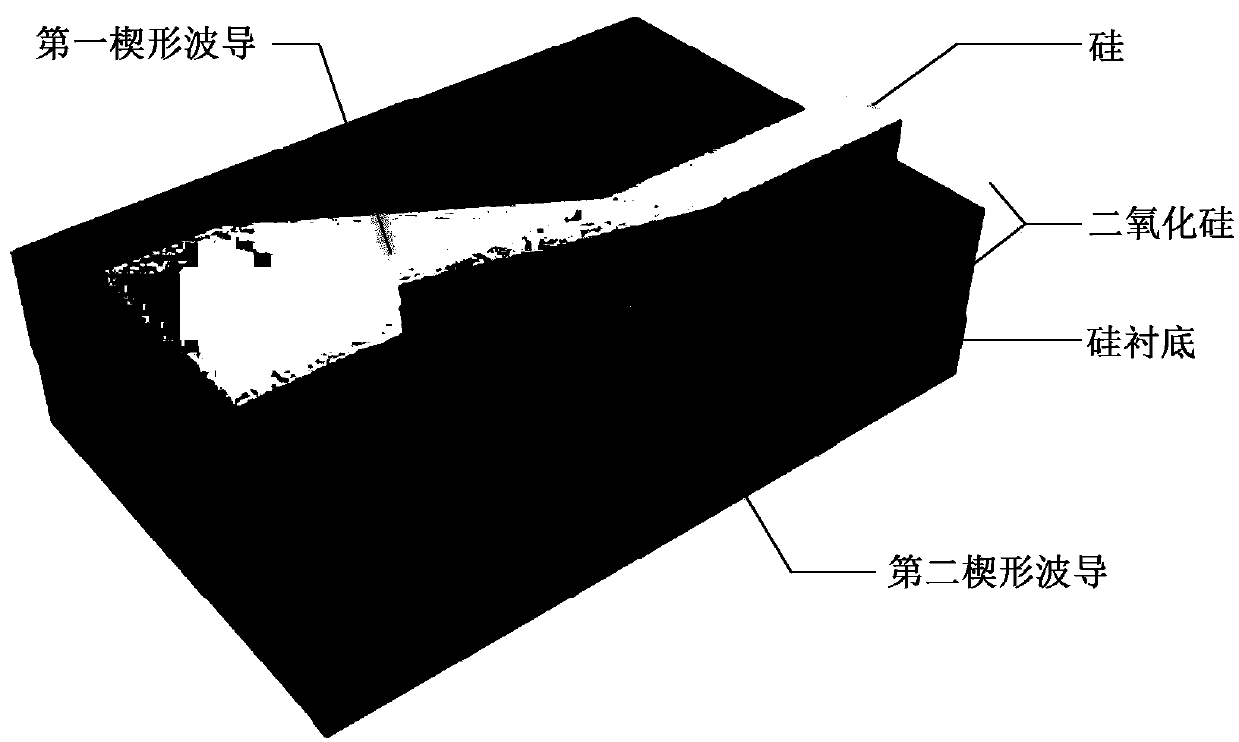

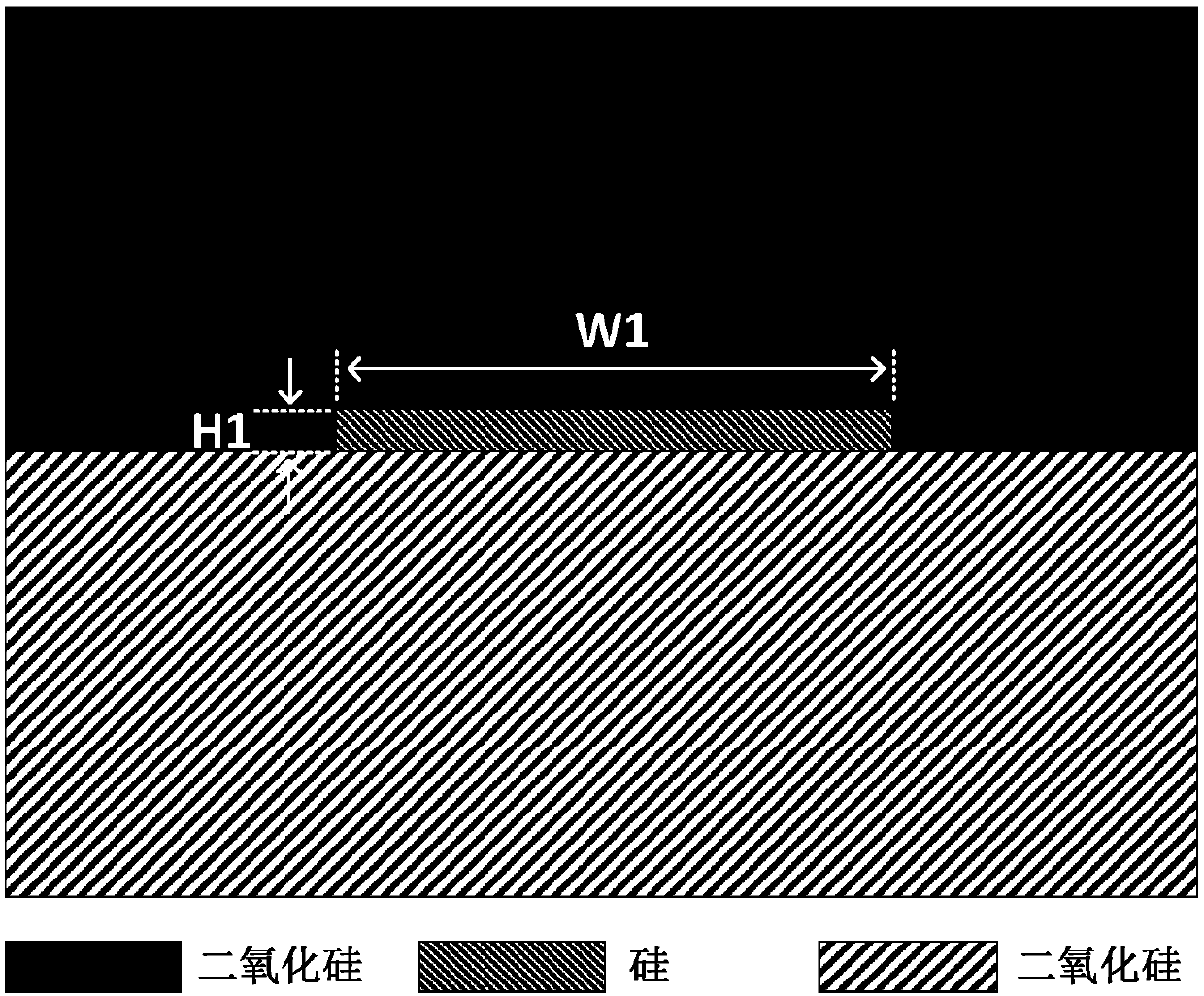

[0056] The thickness of the waveguide layer of the 220nm wafer of the SOI process platform applied to the speckle converter in the embodiment of the present invention is 220nm. The lower cladding material is silicon dioxide with a thickness of 2 μm, and the upper cladding material is silicon dioxide with a thickness of 2˜3 μm.

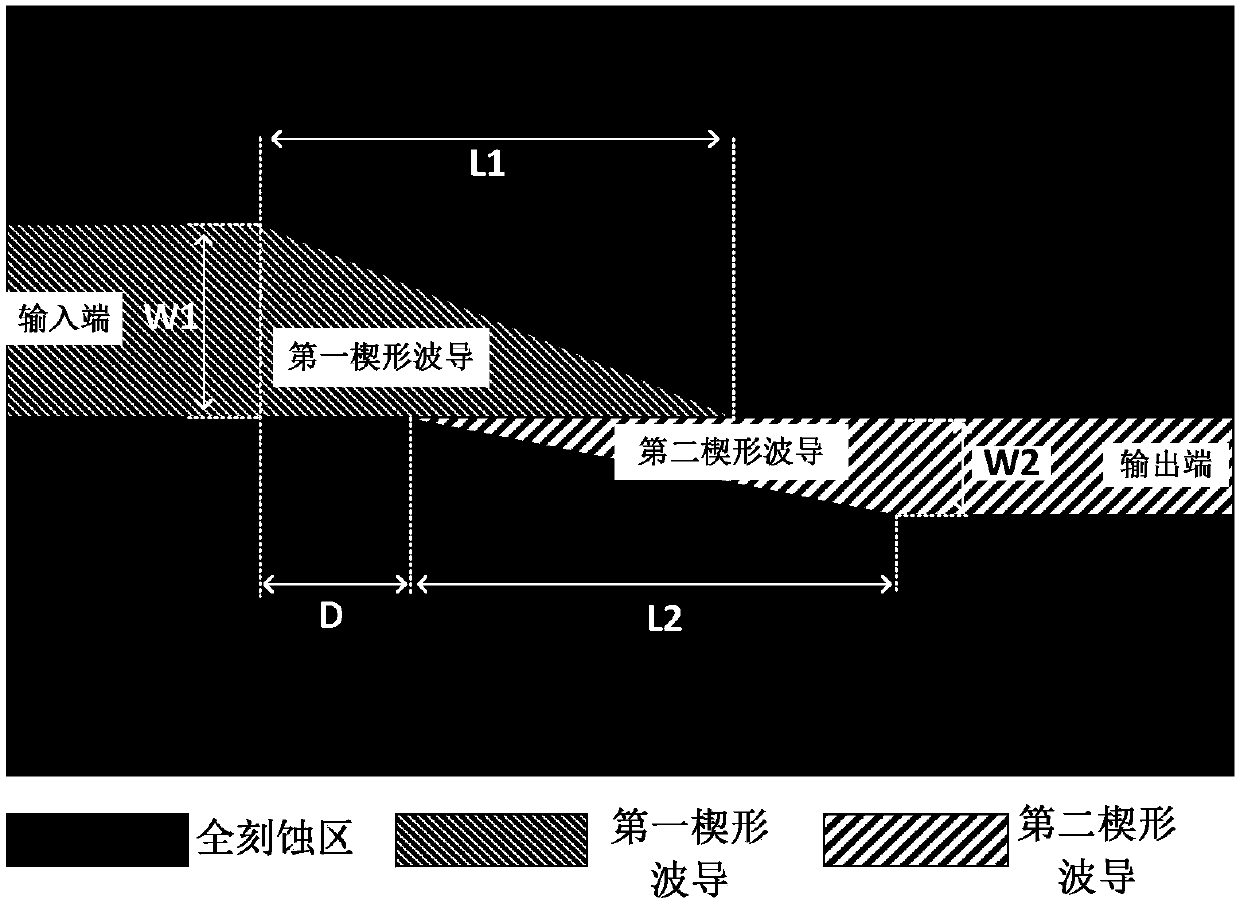

[0057] For the speckle converter shown in Figure 1, the corresponding parameters in this embodiment are: the thickness of the first wedge-shaped waveguide is 70nm, which can be processed by using 150nm deep ridge etching technology to process the silicon waveguide layer with a thickness of 220nm. The width of the input end of the first wedge-shaped waveguide is 4.0 μm. The overall length of the first wedge-shaped waveguide is 20 μm. The thickness of the second wedge-shaped waveguide is 220nm, which is consistent with the thickness of the silicon strip waveguide on the waveguide platform. The width of the output end of the second wedge-shaped waveguid...

Embodiment 2

[0063] The embodiment of the present invention adopts a 310nm wafer on an SOI process platform, and the thickness of its waveguide layer is 300nm. The lower cladding material is silicon dioxide with a thickness of 0.8 μm. The upper cladding material is silicon dioxide, and its thickness is 2-3 μm. For the speckle converter shown in Figure 1, the corresponding parameters in this embodiment are: the thickness of the first wedge-shaped waveguide is 65nm, which can be formed by processing a silicon waveguide layer with a thickness of 300nm by using 235nm deep ridge etching technology . The width of the input end of the first wedge-shaped waveguide is 4.0 μm. The overall length of the first wedge-shaped waveguide is 20 μm. The thickness of the second wedge-shaped waveguide is 300 nm, which is consistent with the thickness of the silicon strip waveguide on the waveguide platform. The width of the output end of the second wedge-shaped waveguide is 0.45 μm. The overall length of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com