Environment-friendly veneer and preparing method thereof

A veneer, environmentally friendly technology, applied in special decorative structures, chemical instruments and methods, decorative arts, etc., can solve the problems of long storage time, health hazards of constructors and users, and achieve fast drying speed, saving working time, The effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

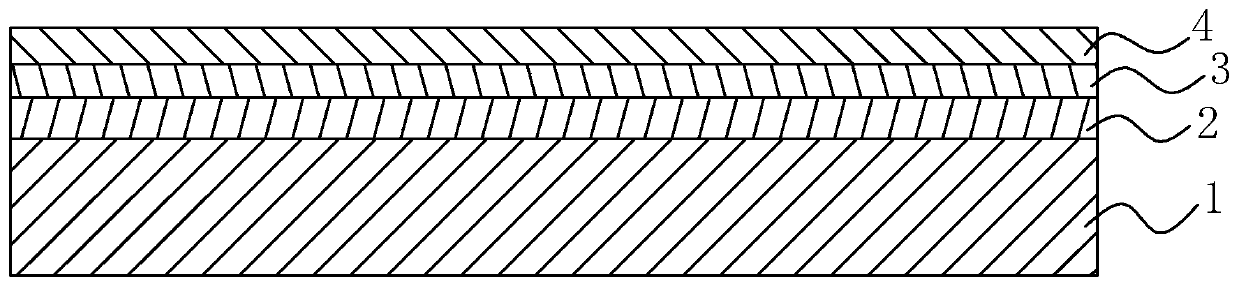

Image

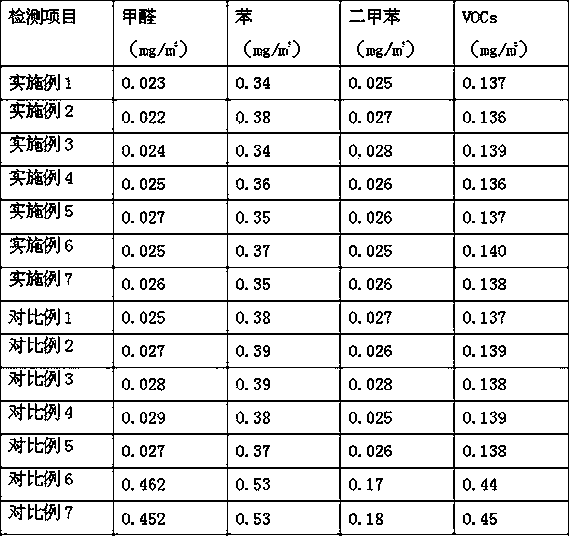

Examples

preparation example 1

[0047] Preparation example 1: (1) According to the ratio in Table 1, soak 10kg of activated carbon fiber and 10kg of distilled water at 50°C for 1 hour, take it out and dry it at a constant temperature of 80°C for 2 hours;

[0048] (2) Add 1 kg of butyl titanate to 3 kg of absolute ethanol and stir for 25 minutes to obtain solution A. Mix 7 kg of absolute ethanol, 1 kg of glacial acetic acid, 20 kg of distilled water and 1 kg of nitric acid solution to form solution B. Mix 5 kg of cerium nitrate and 5 kg of Add ammonia water to solution B, stir evenly, add solution B to solution A, stir evenly, and let stand for 1 hour to obtain a uniform colloid;

[0049] (3) Immerse the activated carbon fiber obtained in step (1) in the colloid obtained in step (2), disperse it by ultrasonic wave for 10 minutes, and after natural air drying, put it into a muffle furnace protected by argon and calcinate at 550°C for 2 hours. Ultrasonic power is 225W;

[0050] (4) Ball mill the product obtain...

preparation example 2

[0054] Preparation Example 2: (1) According to the ratio in Table 1, soak 13kg of activated carbon fiber and 13kg of distilled water at 55°C for 1.3h, take it out and dry it at a constant temperature of 83°C for 2.5h;

[0055] (2) Add 3 kg of butyl titanate to 4 kg of absolute ethanol, stir for 28 minutes to obtain solution A, mix 8 kg of absolute ethanol, 3 kg of glacial acetic acid, 27 kg of distilled water and 3 kg of nitric acid solution to form solution B, mix 8 kg of cerium nitrate and 8 kg Add ammonia water to solution B, stir evenly, add solution B to solution A, stir evenly, and let stand for 1 hour to obtain a uniform colloid;

[0056] (3) Immerse the activated carbon fiber obtained in step (1) in the colloid obtained in step (2), disperse it by ultrasonic wave for 13 minutes, and after natural air drying, put it into a muffle furnace protected by argon and calcinate at 580°C for 2.3 hours , the ultrasonic power is 230W;

[0057] (4) Ball mill the result of step (3)...

preparation example 3

[0059] Preparation Example 3: (1) According to the ratio in Table 1, soak 15kg of activated carbon fiber and 16kg of distilled water at 60°C for 1.5h, take it out and dry it at a constant temperature of 85°C for 3h;

[0060] (2) Add 5kg of butyl titanate to 5kg of absolute ethanol, stir for 30min to obtain solution A, mix 10kg of absolute ethanol, 5kg of glacial acetic acid, 34kg of distilled water and 5kg of nitric acid solution to form solution B, mix 10kg of cerium nitrate and 10kg of Add ammonia water to solution B, stir evenly, add solution B to solution A, stir evenly, and let it stand for 1.5h to obtain a uniform colloid;

[0061] (3) Immerse the activated carbon fiber obtained in step (1) in the colloid obtained in step (2), disperse it by ultrasonic wave for 15 minutes, and after natural air drying, put it into a muffle furnace protected by argon and calcinate at 600°C for 2.5 hours , the ultrasonic power is 235W;

[0062] (4) Ball mill the product obtained in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com