Method for dynamically and continuously producing ultrahigh-strength gypsum

A high-strength gypsum and ultra-high-strength technology, applied in the field of high-quality utilization of industrial by-product gypsum, can solve the problems of discontinuous process, high cost, poor waterproof performance, etc., achieve comprehensive utilization of resources, reduce production costs, and reduce the amount of addition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with specific examples.

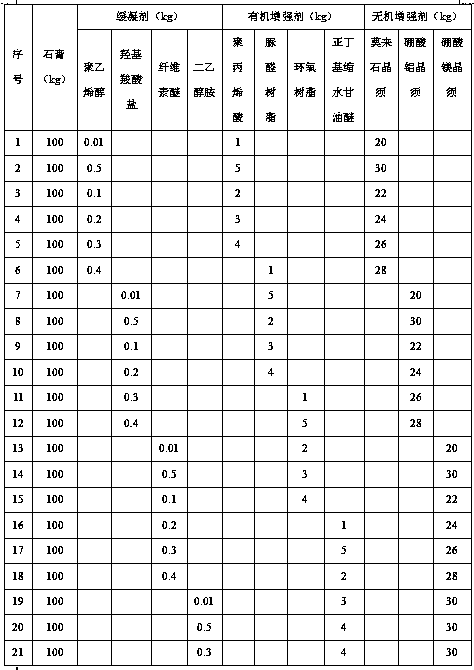

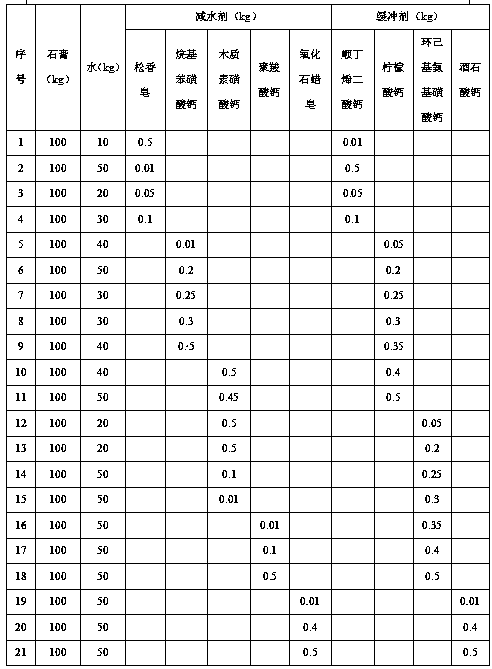

[0033] (1) After adding water, water reducing agent and buffering agent to the gypsum and mixing them evenly, pump them into the autoclave to undergo a crystal transformation reaction to obtain high-strength gypsum. The formula of high-strength gypsum is shown in Table 1.

[0034] Table 1

[0035]

[0036] (2) After continuously injecting high-strength gypsum into the particle size control kettle, pump it into the stabilization kettle, add retarder, and stir evenly, then pump the high-strength gypsum into the liquid-solid separator for dehydration, and the dehydrated high-strength gypsum passes through the material sealing device Continuously enter the drying and disintegrating machine, and obtain high-strength gypsum dry powder through the dust collector, and add organic and inorganic reinforcing agents to the high-strength gypsum dry powder to obtain ultra-high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com