Self-cleaning ceramic tile

A self-cleaning and ceramic tile technology, which is applied in the field of tile processing, can solve the problems that affect the decoration and use effect of tiles, the surface of tiles is prone to scratches, and the tiles lose their surface luster, so as to maintain cleanliness and luster for a long time, inhibit the growth of bacteria, Good anti-fouling self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

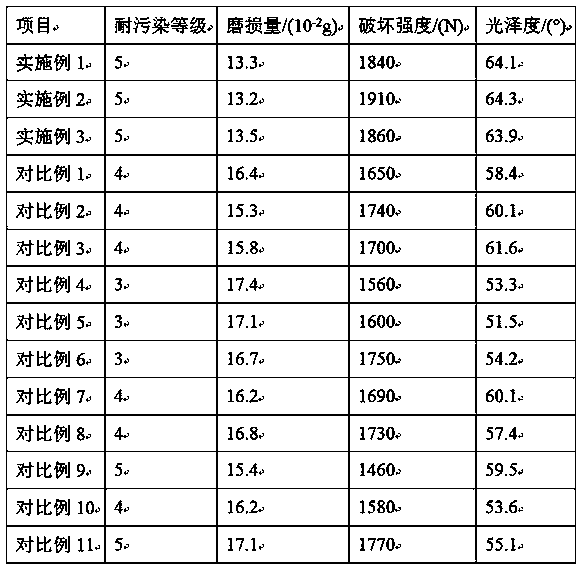

Examples

Embodiment 1

[0022] A self-cleaning ceramic tile made of the following raw materials in parts by weight: lithium-based montmorillonite 52, modified bentonite 33, talcum powder 24, waste ceramics 15, light calcium powder 10, nano-titanium dioxide 1.7, nano-anion powder 1.2, surface Treatment agent 1.1.

[0023] For the modified bentonite, crush the bentonite to 120 mesh, add a tartaric acid solution with a concentration of 65 mg / L that is 2 times the weight of the bentonite to the bentonite, stir evenly, let stand for 20 minutes, and heat to 100° C. at 3° C. / min. Keep warm for 10 minutes, then add polyethylene terephthalate with 5% bentonite weight, mix evenly, heat slowly to 240°C, keep warm and stir for 20 minutes, it can improve the adhesion and gloss of bentonite, and increase the strength and gloss of tiles , To improve the grade of tiles, get modified bentonite.

[0024] The waste ceramics are one or both of ceramic residues and ceramic scraps, crushed to 80 mesh, heated to 260°C at ...

Embodiment 2

[0034] A self-cleaning ceramic tile made of the following raw materials in parts by weight: lithium-based montmorillonite 53, modified bentonite 34, talc powder 25, waste ceramics 16, light calcium powder 11, nano-titanium dioxide 1.8, nano-anion powder 1.3, surface Treatment agent 1.2.

[0035] For the modified bentonite, crush the bentonite to 140 mesh, add a tartaric acid solution with a concentration of 68 mg / L that is 2.5 times the weight of the bentonite to the bentonite, stir evenly, let stand for 25 minutes, and heat to 110° C. at 3.5° C. / min. Keep warm for 13 minutes, then add polyethylene terephthalate with 6% bentonite weight, mix evenly, heat slowly to 250°C, keep warm and stir for 25 minutes, it can improve the adhesion and gloss of bentonite, and increase the strength and gloss of tiles , To improve the grade of tiles, get modified bentonite.

[0036] The waste ceramics are one or both of ceramic residues and ceramic scraps, crushed to 90 mesh, heated to 290°C a...

Embodiment 3

[0046] A self-cleaning ceramic tile made of the following raw materials in parts by weight: lithium-based montmorillonite 54, modified bentonite 35, talc powder 26, waste ceramics 17, light calcium powder 12, nano-titanium dioxide 1.9, nano-anion powder 1.4, surface Treatment agent 1.3.

[0047] For the modified bentonite, crush the bentonite to 160 mesh, add a tartaric acid solution with a concentration of 70 mg / L that is 3 times the weight of the bentonite to the bentonite, stir evenly, let stand for 30 minutes, and heat to 120° C. at 4° C. / min. Keep warm for 15 minutes, then add polyethylene terephthalate with 7% bentonite weight, mix evenly, heat slowly to 260°C, keep warm and stir for 30 minutes, it can improve the adhesion and gloss of bentonite, and increase the strength and gloss of tiles , To improve the grade of tiles, get modified bentonite.

[0048] The waste ceramics mentioned above are one of ceramic residues and ceramic scraps or any mixture of both, crushed to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com