A non-migrating hydrophilic anti-fog masterbatch for polyolefin film and its preparation

A non-migration, polyolefin technology, applied in the field of anti-fog masterbatch, can solve the problems of poor anti-fog effect and unsustainable anti-fog effect, and achieve the effects of long-lasting anti-fog effect, improved smoothness, and good anti-sticking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

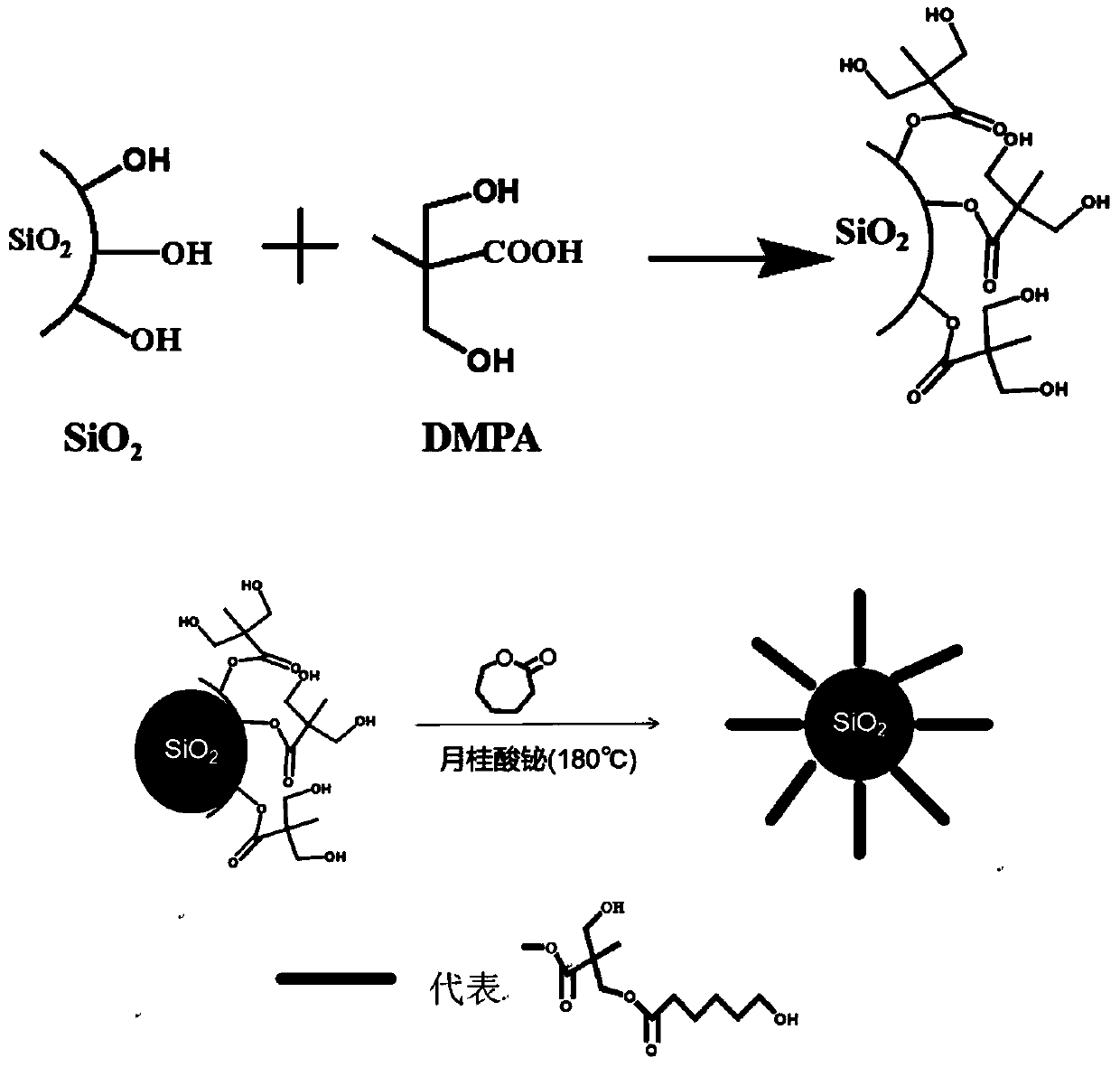

[0033] A kind of preparation method of non-migratory hydrophilic anti-fog masterbatch for polyolefin film, such as figure 1 It mainly includes the following steps:

[0034] (1) SiO 2 Surface hydroxylation treatment: under nitrogen protection, add anhydrous toluene to reflux, and the synthesized SiO 2 Activated at 260°C for 10h. And through the method of acid-base titration, it was found that the number of hydroxyl groups on the surface of the activated silica increased.

[0035] (2) Hydroxylate the surface of SiO 2 Dispersion in xylene under nitrogen protection according to the "quasi-one-step method", DMPA and surface hydroxylation of SiO 2According to the molar ratio of 1:1, it was added every 1 hour, and the reaction was carried out for 10 hours (the amount added each time was 1:1 in molar ratio). The reaction was stirred at the same temperature; after the reaction was stopped, the product was suction filtered, washed with xylene and anhydrous ethanol, and then placed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com