Preparation method and application of up-conversion material NaYF4:Yb,Er@M

A technology for converting materials and metals, which is applied in nanotechnology, luminescent materials, nanotechnology, etc. for materials and surface science. Low efficiency and other problems, to achieve the effect of easy large-scale production, increased radiation attenuation rate, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

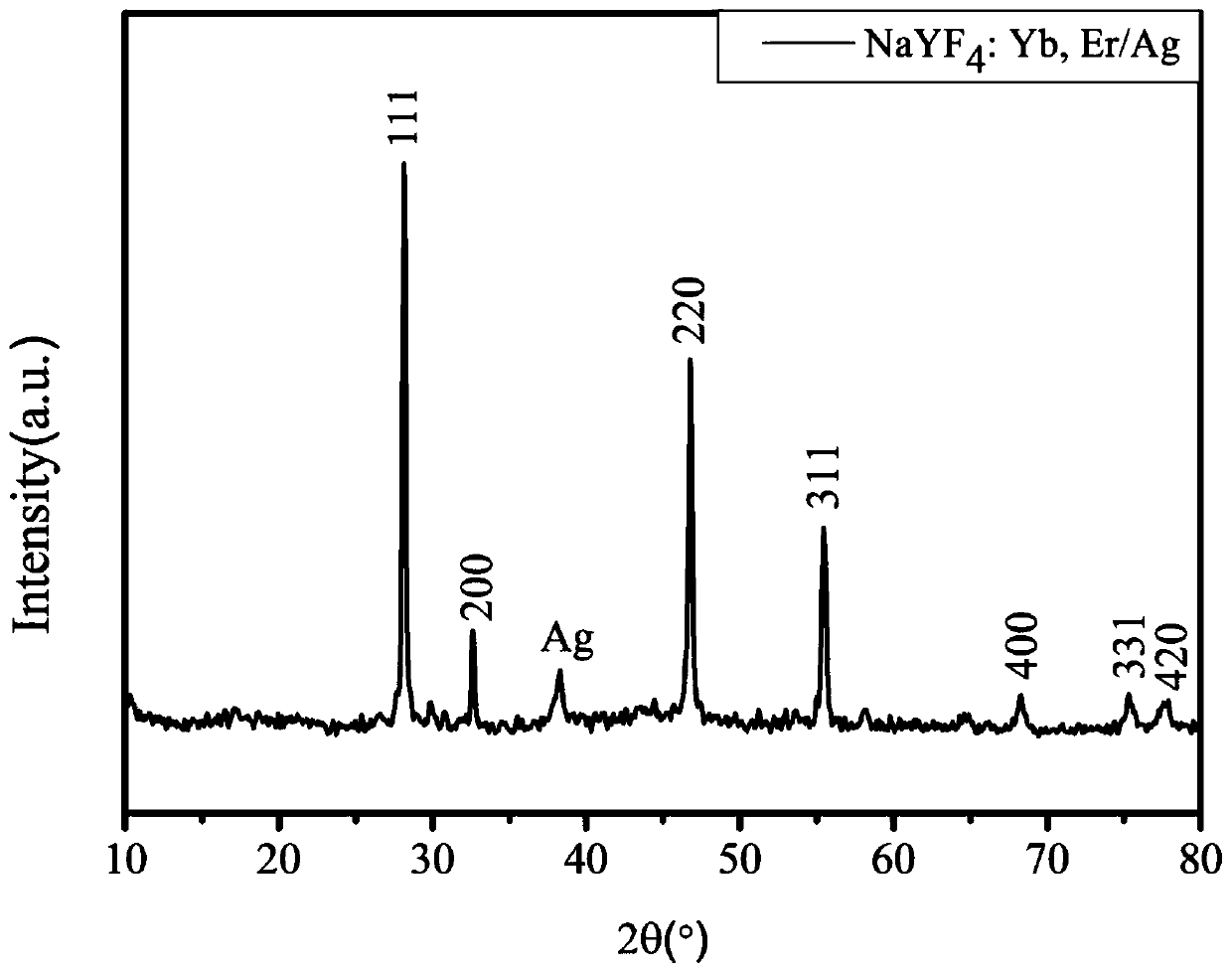

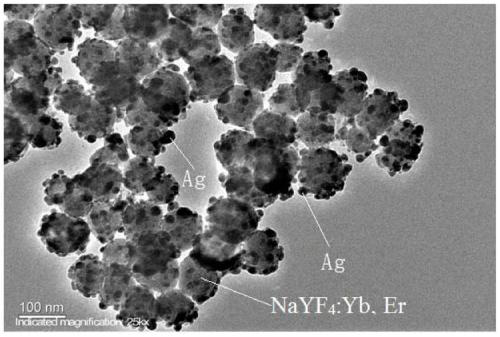

[0040] A NaYF 4 : The preparation method of Yb,Er@Ag upconversion material, comprising the following steps:

[0041] (1) NaYF 4 :Yb,Er nanoparticles were sonicated for 20min, dispersed in AgNO 3 The solution was made into 0.1mg / mL solution, aged for 15h, when NaYF 4 : Ag is fully adsorbed on the surface of Yb,Er nanoparticles + Then, the precursor was obtained by centrifugation, and the precursor was rinsed twice with deionized water;

[0042] (2) Disperse the precursor rinsed in step (1) in 3 mL of NaBH with a concentration of 5 mg / mL 4 In the solution, stir for 8 min to facilitate the Ag + Fully reduced to Ag particles, after completion, the reaction solution is centrifuged to obtain a solid product;

[0043] (3) After rinsing the solid product obtained in step (2) with deionized water for 4 times, it was dried at 70° C. for 4 hours to obtain NaYF 4 : Yb,Er@Ag upconversion material.

Embodiment 2

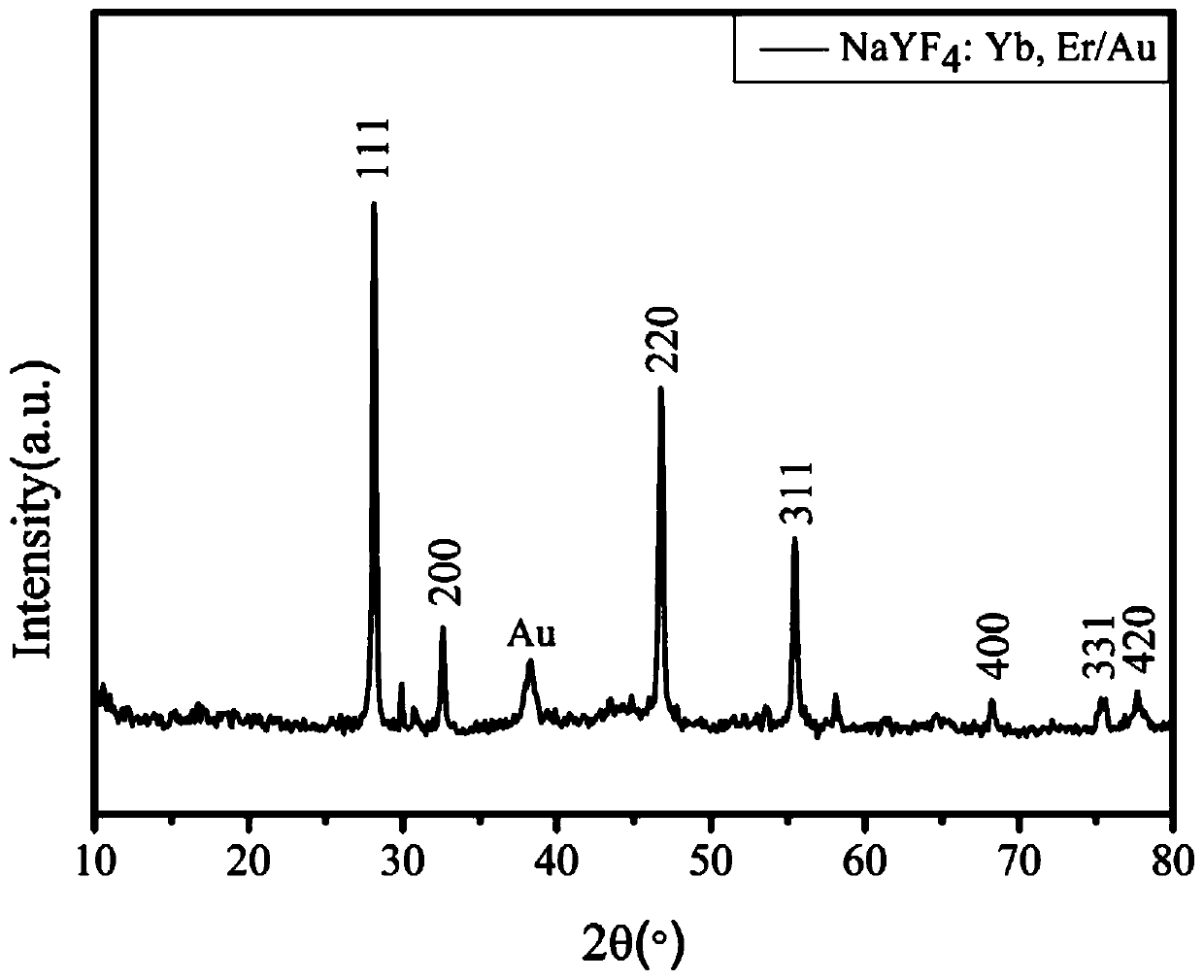

[0045] A NaYF 4 : The preparation method of Yb,Er@Au upconversion material, comprising the following steps:

[0046] (1) NaYF 4 :Yb,Er nanoparticles were sonicated for 100min, dispersed in HAuCl 4 The solution was made into 0.1mg / mL solution, aged for 24h, when NaYF 4 : After the surface of Yb, Er nanoparticles fully adsorbed Au(III), the precursor was obtained by centrifugation, and the precursor was rinsed with deionized water for 3 times;

[0047] (2) Disperse the precursor rinsed in step (1) in 5 mL of sodium citrate solution with a concentration of 8 mg / mL, stir for 8 min, so as to fully reduce Au(III) into Au particles, and centrifuge the reaction solution after completion separation to obtain a solid product;

[0048] (3) After rinsing the solid product obtained in step (2) with deionized water for 5 times, it was dried at 60° C. for 6 hours to obtain NaYF 4 : Yb,Er@Au upconversion material.

Embodiment 3

[0050] A NaYF 4 : The preparation method of Yb,Er@Ag upconversion material, comprising the following steps:

[0051] (1) NaYF 4 :Yb,Er nanoparticles were sonicated for 1min, dispersed in AgNO 3 The solution was made into 1mg / mL solution, aged for 1h, when NaYF 4 : Ag is fully adsorbed on the surface of Yb,Er nanoparticles + Then, the precursor was obtained by centrifugation, and the precursor was rinsed twice with deionized water;

[0052] (2) Disperse the precursor rinsed in step (1) in 5 mL of ethylene glycol solution with a concentration of 5 mg / mL, and stir for 5 min, so as to facilitate the removal of Ag + Fully reduced to Ag particles, after completion, the reaction solution is centrifuged to obtain a solid product;

[0053] (3) After rinsing the solid product obtained in step (2) with deionized water for 4 times, it was dried at 80° C. for 2 hours to obtain NaYF 4 : Yb,Er@Ag upconversion material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com