A kind of two-component antibacterial cellulose material and its preparation method and application

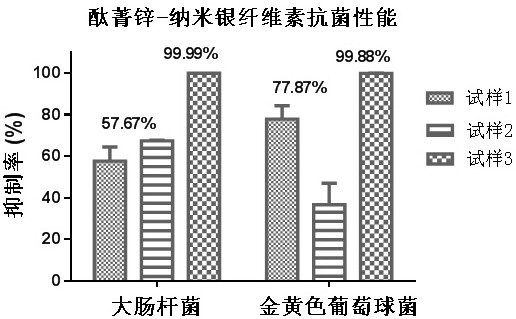

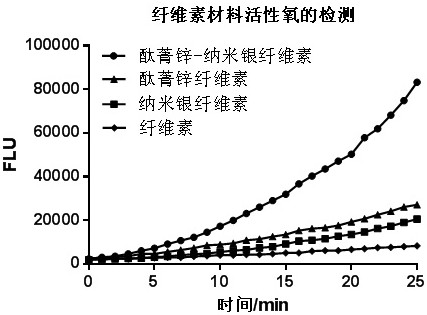

A cellulose, two-component technology, applied in plant fibers, fiber treatment, textiles and papermaking, etc., can solve the problem that the antibacterial effect of composite cellulose materials far exceeds that of a single photosensitizer or a single silver nanoparticle, and the antibacterial effect is limited, etc. problem, to achieve the effect of broad spectrum of antibacterial action, short diffusion distance and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

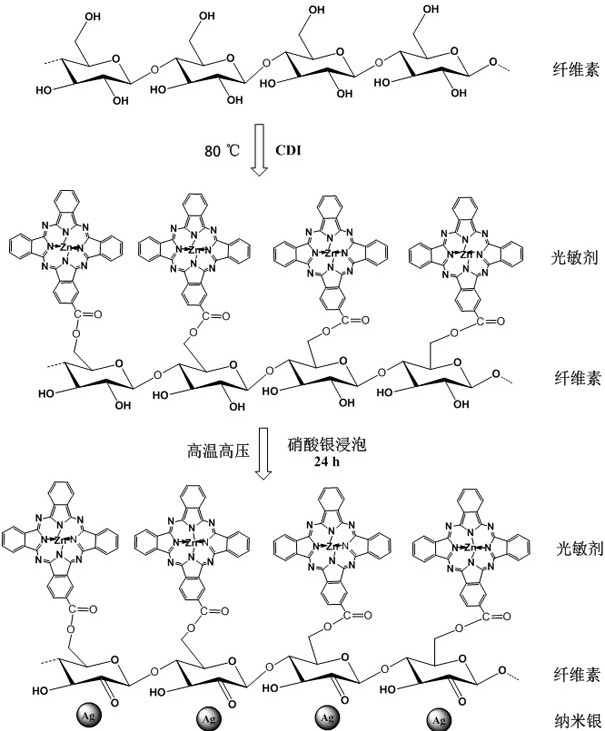

[0021] Embodiment 1: Preparation monocarboxy phthalocyanine zinc-nanometer silver cellulose

[0022] 1. Dissolve β-monocarboxyl substituted zinc phthalocyanine in N,N-dimethylformamide (DMF) solvent, add twice the molar equivalent of N,N-carbonyldiimidazole (CDI), and activate at 80°C React for 3 hours, then add cellulose fabric, shake and react at 80°C for 24 hours, then wash off the unreacted β-monocarboxyl substituted zinc phthalocyanine with DMF, wash the fabric several times with water, and dry to obtain zinc phthalocyanine cellulose .

[0023] 2. Soak the zinc phthalocyanine cellulose prepared in the first step in the silver nitrate solution at room temperature for 24 hours, and react for 10 minutes under high temperature and high pressure conditions with a temperature of 121°C and a pressure of 0.1Mpa. The fabric was washed with clear water for 3 times, and dried to obtain zinc phthalocyanine-nanometer silver cellulose.

Embodiment 2

[0024] Example 2: Preparation of pyropheophorbide-a-nano silver cellulose

[0025] 1. Dissolve pyropheophorbide-a in N,N-dimethylformamide (DMF) solvent, add twice the molar equivalent of O-benzotriazole-tetramethyluronium hexafluorophosphate (HBTU), N,N-diisopropylethylamine (DIEA) with a total volume ratio of 0.5%, activated at room temperature for 0.5 hours, then added to cellulose fabric, shaken at 80°C for 24 hours, and then washed with DMF Wash the unreacted pyropheophorbide-a fabric several times with water, and dry to obtain pyropheophorbide-a cellulose.

[0026] 2. Soak the pyropheophorbide-a cellulose prepared in the first step in silver nitrate solution at room temperature for 20 hours, and react under high temperature and high pressure conditions with a temperature of 121°C and a pressure of 0.1Mpa. After 10 minutes, take out and wash the fabric with clean water for 3-5 times, and dry to obtain pyropheophorbide-a-nano silver cellulose.

Embodiment 3

[0027] Embodiment 3: Preparation of chlorin e6-nanometer silver cellulose

[0028] 1. Dissolve chlorin e6 in N,N-dimethylformamide (DMF) solvent, add six times the molar equivalent of 1-hydroxybenzotriazole (HOBT) and dicyclohexylcarbodiimide ( DCC), activated at 0°C for 30 minutes, then added cellulose fabric, oscillated for 24 hours at 80°C, then washed away the unreacted chlorin e6 with DMF, washed the fabric several times with water, and dried to obtain Pyropheophorbide-a cellulose.

[0029] 2. Soak the chlorin e6 cellulose prepared in the first step in the silver nitrate solution at room temperature for 20 hours, and react for 10 minutes under high temperature and high pressure conditions with a temperature of 121°C and a pressure of 0.1Mpa Take out and wash the fabric with clean water for 3-5 times, and dry to obtain chlorin e6-nanometer silver cellulose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com