A method for improving the negative electrode performance of lithium-ion batteries

A lithium-ion battery and negative electrode technology, applied in the field of electrochemistry, can solve the problems of low initial charge and discharge efficiency of the battery, unresolved lithium salt loss, and unfavorable practical application, so as to improve cycle performance and capacity retention rate, and improve electrochemical performance. Stability, the effect of improving storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

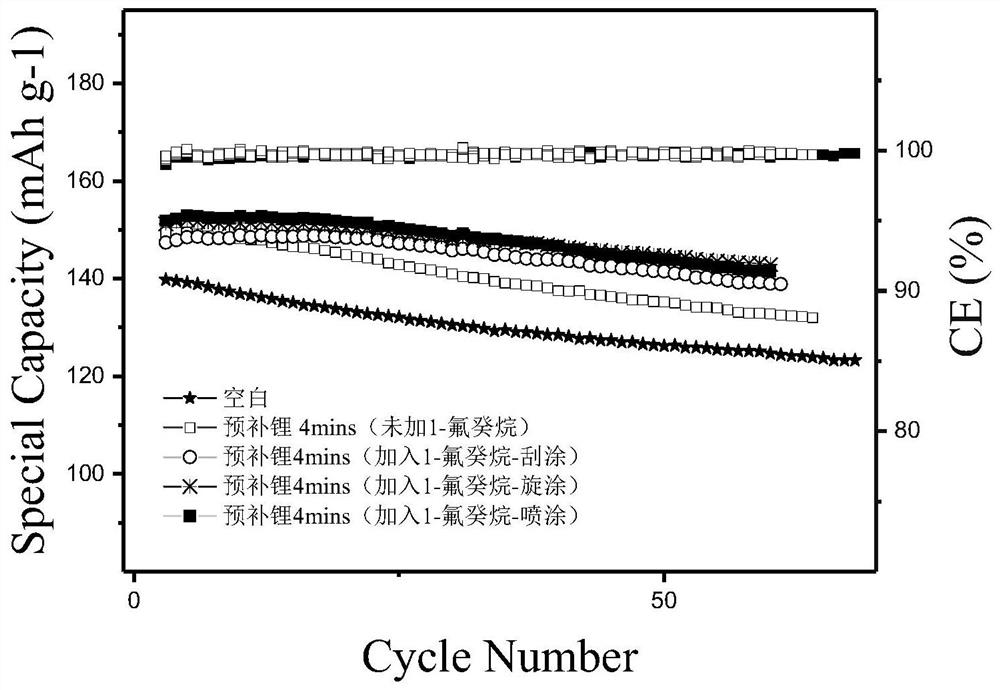

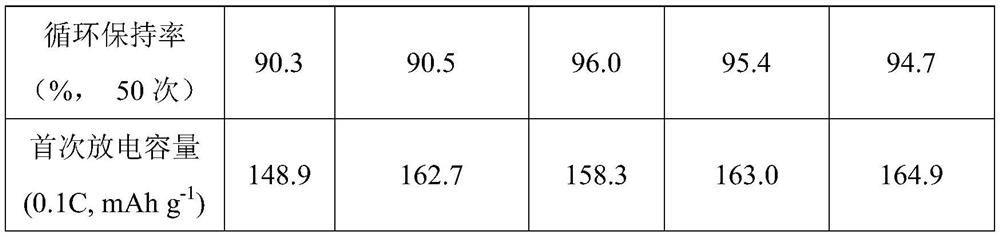

Embodiment 1

[0031] Dissolve 80 μL of 1-fluorodecane in 5 ml of anhydrous cyclohexane, perform ultrasonication for 5 mins, apply 5 mL of the solution on the negative electrode sheet (carbon-based negative electrode) with a spatula at a height of 100 μm, and drop the electrolyte solution to completely cover the entire surface On the surface of the pole piece, cover the surface with a clean lithium foil, apply a pressure of 4MPa, and pre-fill lithium for 4mins. The pole piece is washed by the solvent DMC, and then dried at 60°C. The negative electrode sheet was punched into an electrode sheet with a diameter of 15 mm, and the corresponding positive electrode sheet was matched to prepare a button-type full battery for electrochemical testing.

Embodiment 2

[0033] The prepared negative electrode sheet was cut into a 7 cm original sheet, and fixed on the table of the spin coater, and the spin coater was started at a rotational speed of 500 r / min. Dissolve 80 μL of 1-fluorohexane in 5 mL of anhydrous cyclopentane, and sonicate for 5 mins. Aspirate 1 ml of the solution through a pipette gun, and slowly drop it onto the center of the negative electrode sheet (titanium-based negative electrode) for spin coating. The electrolyte solution was dropped on the surface of the negative electrode and completely covered the entire surface of the electrode, and a clean lithium foil was covered on the surface, and the pressure was 0.5 MPa, and the lithium was pre-filled for 60 minutes. The pole piece is washed by the solvent DMC, and then dried at 60°C. The negative electrode sheet was punched into an electrode sheet with a diameter of 15 mm, and the corresponding positive electrode sheet was matched to prepare a button-type full battery for el...

Embodiment 3

[0035] Dissolve 800 μL of 1-fluorobutane in 50 mL of anhydrous cycloheptane, and sonicate for 5 mins. Take 20mL of the solution and put it into a spraying machine, and spray it at a certain rate against the negative electrode sheet (silicon-based negative electrode) with a side length of 10cm until the solution is sprayed, then drop the electrolyte on the surface of the negative electrode sheet and completely cover the entire surface of the electrode sheet , cover the surface with a clean lithium foil, and apply a pressure of 25MPa, and pre-supplement lithium for 1min. The pole piece is washed by the solvent DMC, and then dried at 60°C. The negative electrode sheet was punched into an electrode sheet with a diameter of 15 mm, and the corresponding positive electrode sheet was matched to prepare a button-type full battery for electrochemical testing.

[0036] In this embodiment, the negative electrode sheet can also be a tin-based negative electrode; the organic solvent can al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com