Composition for forming optical film, optical film and polarizing plate comprising same

A technology of optical film and composition, applied in the direction of optics, optical elements, coatings, etc., can solve the problems of inability to properly express anti-glare properties, deterioration of optical properties of anti-glare layers, insufficient adhesion and hardness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0121]

[0122] (1) Preparation of a composition for forming an antiglare layer

[0123] The components shown in Table 1 and Table 2 below were uniformly mixed to prepare a composition for forming an optical film (antiglare layer). The contents of all components used in Table 1 and Table 2 are shown in parts by weight.

[0124] [Table 1]

[0125]

[0126] [Table 2]

[0127]

[0128] 1) THFA: tetrahydrofurfuryl alcohol

[0129] 2) HEA: 2-hydroxyethyl acrylate

[0130] 3) UA-306T: (Kyoeisha): Hexafunctional acrylate-based compound formed by reacting toluene diisocyanate with two pentaerythritol triacrylates

[0131] 4) Beamset 371 (ARAKAWA CHEMICAL): A polymer in which epoxy acrylate functional groups with a functionality of about 50 or more are bonded to a polyurethane / polyester backbone

[0132] 5) 8BR-500 (TAISEI FINE CHEMICAL): A polymer in which urethane acrylate functional groups having a functionality of about 40 are bonded to a polyacryl main chain

[0133]...

Embodiment 1 to 6 and comparative example 1 to 7

[0140]

[0141]As shown in Table 3 and Table 4 below, the compositions prepared in Preparation Examples 1 to 6 or Comparative Preparation Examples 1 to 7 were respectively coated on a PET base film (or a thickness of 60 μm) with a thickness of 80 μm and a refractive index of 1.6 to 1.7. and acrylic base film with a refractive index of 1.4 to 1.6), dry at 90°C for 1 minute, and then use 150mJ / cm 2 UV irradiation to prepare the anti-glare layer.

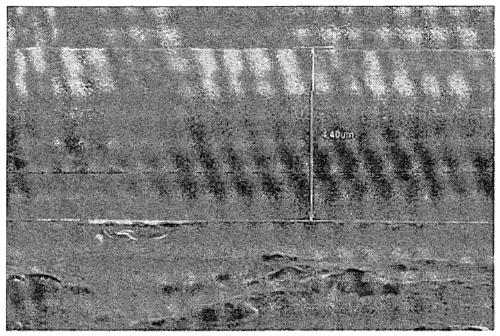

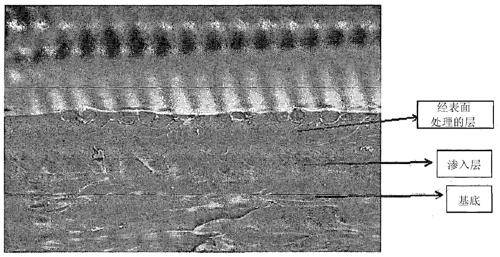

[0142] An anti-glare layer is formed and an optical film is prepared. The cross-sections of the optical films of Examples 2 and 3 were observed with an electron microscope, and the formation of the penetration layer was confirmed. The electron micrographs of embodiment 2 and 3 are shown in respectively figure 1 and figure 2 in (in figure 1 In , light-transmitting fine particles were not observed due to the viewing direction). In the same manner, it was confirmed whether or not an infiltration layer was formed in the remaining...

experiment example

[0143]

[0144] The physical properties of the optical films prepared above were measured according to the following methods, and the results are shown in Table 3 and Table 4 below.

[0145] 1. Measurement of Refractive Index

[0146] The refractive indices of the adhesive and the antiglare layer contained in the optical film were measured using an ellipsometer in a state coated on a wafer. More specifically, the refractive index of the adhesive, anti-glare layer, and low-refractive index layer was measured by a method in which each composition was applied to a 3 cm x 3 cm wafer, and coated using a spin coater (coating conditions: 1500 rpm, 30 seconds), dried at 90°C for 2 minutes, and heated at 180mJ / cm 2 irradiated with ultraviolet light. Thus, each coating layer having a thickness of 100 nm was formed.

[0147] The ellipsometric degree of the coating layer was measured at an incident angle of 70° in a wavelength range of 380 nm to 1000 nm by using a J.A. Woollam Co. M-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com