Method for preparing ternary copolymerized metalize cast polypropylene resin composition

A technology for ternary copolymerization of polypropylene and resin composition, which is applied in the field of preparation of polypropylene resin composition, can solve the problems of lower material crystallization performance, high n-hexane extract, and limited application range, and achieve low cost and excellent preparation process Simple, Environmentally Friendly Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

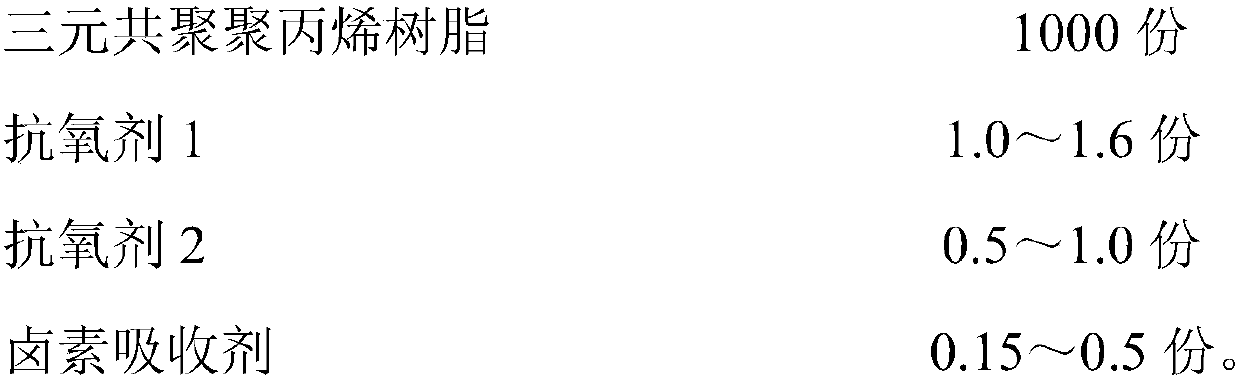

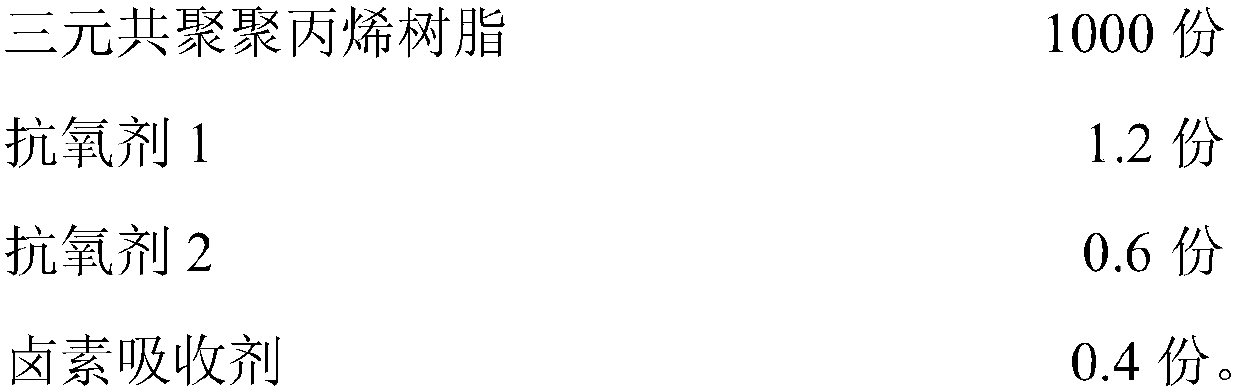

[0040] According to the proportioning shown in table 1, prepare aluminized terpolymer polypropylene casting film resin composition:

[0041] 1) Preparation of ternary copolymerization polypropylene resin base material

[0042] With propylene as the main raw material, 1-butene and ethylene as comonomers, in a hydrogen atmosphere, under the action of a catalyst (the catalyst is composed of DQC catalyst, triethylaluminum TEAL and electron donor DONOR-D, the three and Propylene feed ratio is: DQC catalyst: triethylaluminum TEAL: electron donor DONOR-D: propylene=0.030~0.036g:0.250~0.310g:0.073~0.093g:1000g), carry out prepolymerization reaction first, then in Copolymerization is carried out in the loop reactor to obtain ternary copolymerization polypropylene resin base material; Wherein, prepolymerization reaction condition is: reaction temperature is 15 ± 1 ℃, and reaction pressure is 3.4 ± 0.1MPa, and reaction time is 30min; Copolymerization reaction condition For: temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com