Quantum dot ink and quantum dot membrane and production method thereof

A quantum dot film and quantum dot technology, applied in the field of liquid crystal display, can solve the problems of affecting the light emitting efficiency and light conversion efficiency of quantum dot film, affecting the curing effect of photocurable resin, and difficult to uniformly disperse quantum dots. Thin, display pure, low shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] S11: Prepare a transparent resin film, such as a PET film.

[0029] S12: Printing the first quantum dot ink and the second quantum dot ink on different regions of the transparent resin film by an inkjet printer with a piezoelectric nozzle (such as a printer equipped with a Ricoh GEN5 nozzle).

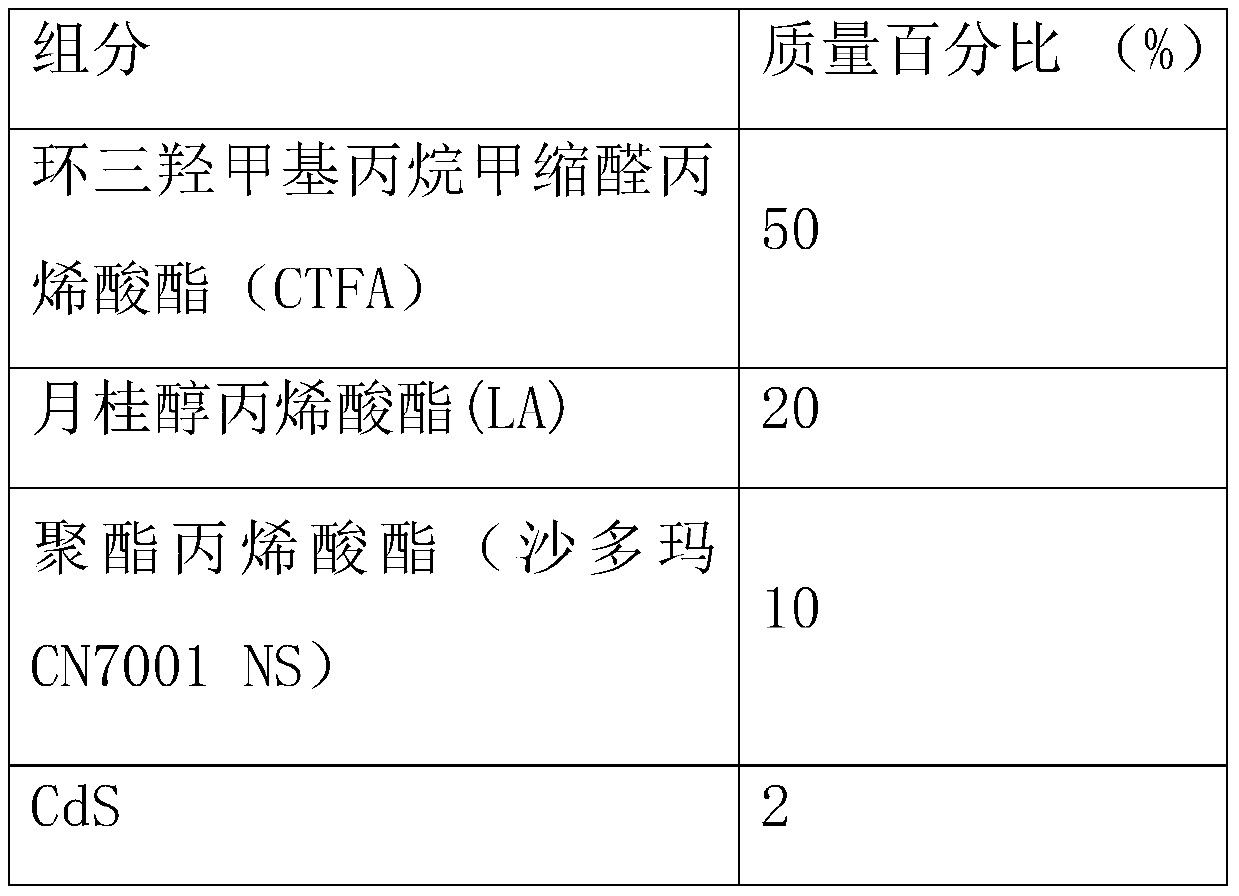

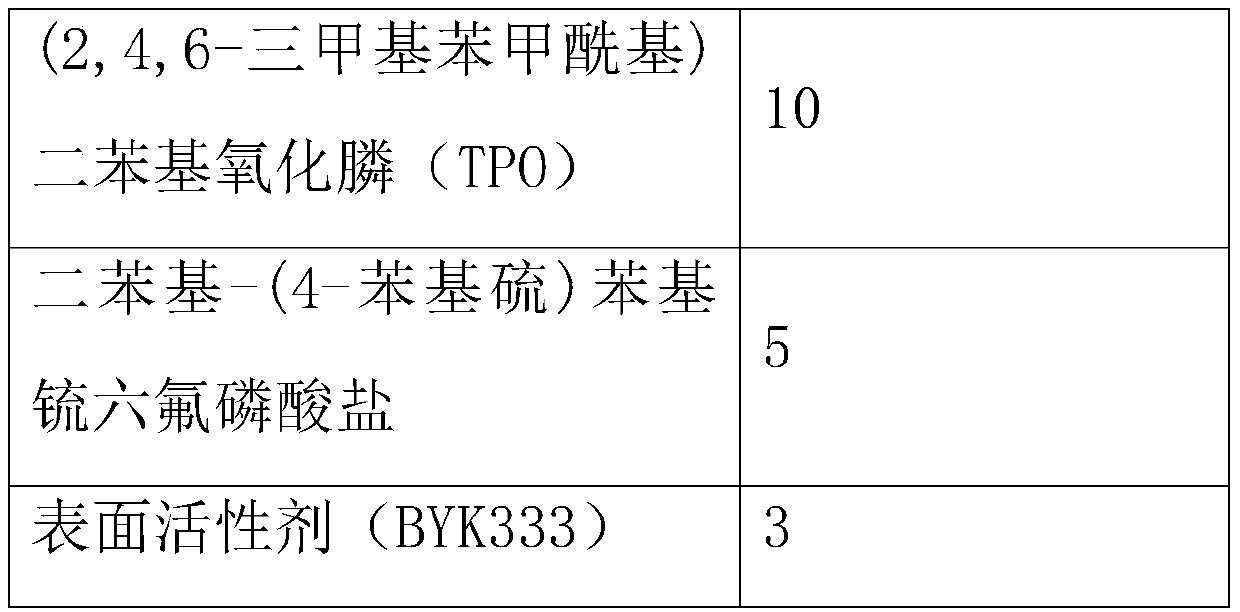

[0030] Wherein, the ratio of the first quantum dot ink is shown in Table 1.

[0031] Table I

[0032]

[0033]

[0034] In this embodiment, the (meth)acrylic monomer of the first quantum dot ink uses a mixed system of CTFA and LA, and the quantum dots CdS can be uniformly distributed in the mixed system. The quantum dot CdS has a particle size of 7 nm, and the quantum dot CdS can be excited by blue light to emit red light. The photoinitiator is a mixture of TPO and diphenyl-(4-phenylthio)phenylsulfonium hexafluorophosphate, and TPO will not affect the luminous efficiency of quantum dots, and will not turn yellow after curing. TPO photoinitiator can also play the role of ...

Embodiment 2

[0042] S21: Prepare a transparent resin film, such as a PET film.

[0043] S22: Print the first quantum dot ink and the second quantum dot ink on different regions of the transparent resin film by using an inkjet printer with a piezoelectric nozzle (such as a printer equipped with an Epson DX5 nozzle).

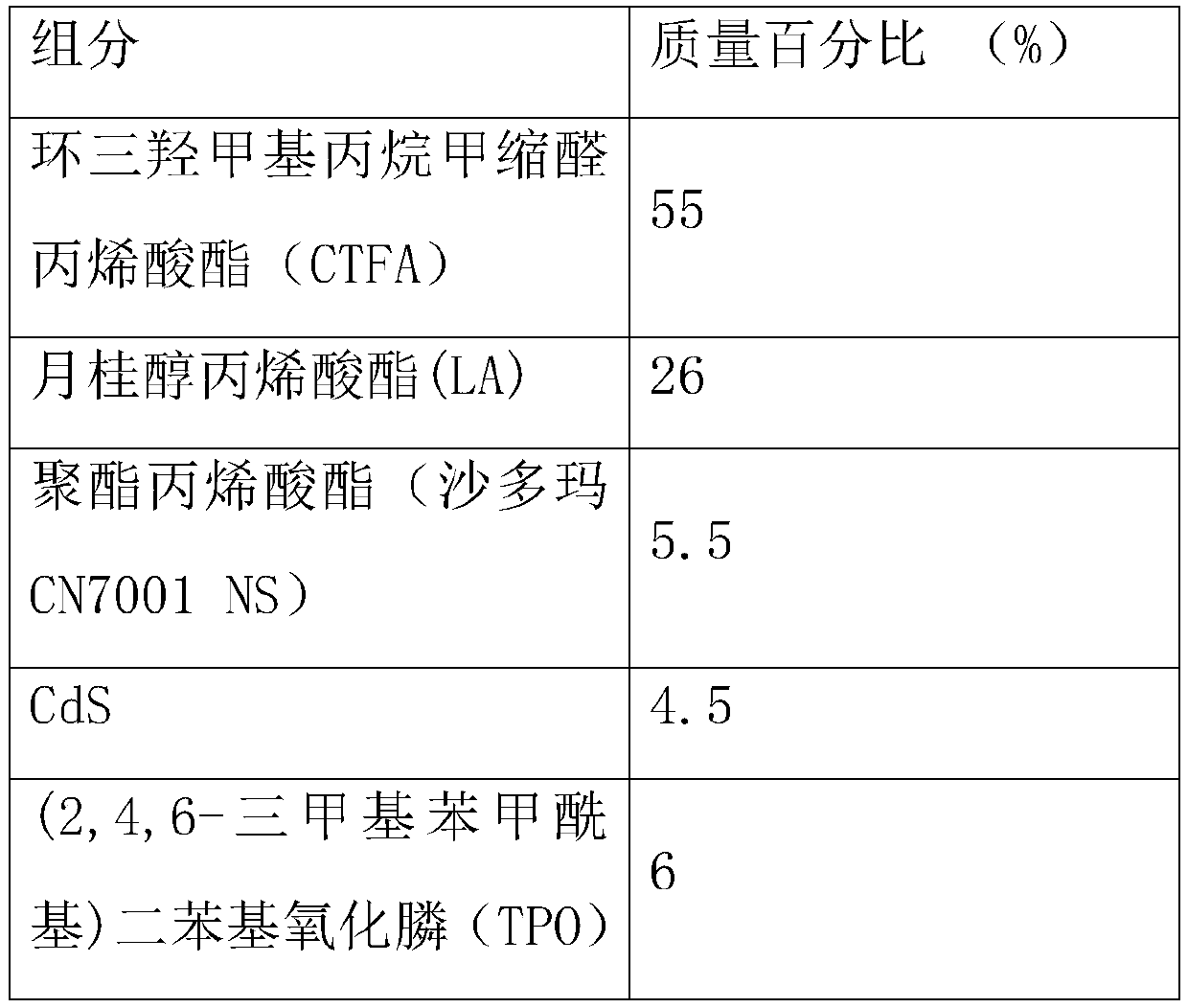

[0044] Among them, the ratio of the first quantum dot ink is shown in Table 3.

[0045] Table three

[0046]

[0047]

[0048] The particle size of InP is 8nm, and the quantum dots can be excited by blue light to emit red light.

[0049] The ratio of the second quantum dot ink is shown in Table 4.

[0050] Table four

[0051]

[0052] The particle size of InP is 4nm, and the quantum dots can be excited by blue light to emit green light.

[0053] S23: Curing the first quantum dot ink and the second quantum dot ink printed in step S22 by UV light, forming a first coating in the area of the first quantum dot ink after curing, and the first coating emits red light u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com