Ebullated bed reactor with internal circulation catalyst and hydrogenation method thereof

A fluidized bed reactor and catalyst technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of few operation means, inability to form a circulation, and difficulty in forming a circulation, and achieve low energy consumption, complete fluidization, To achieve the effect of inner loop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

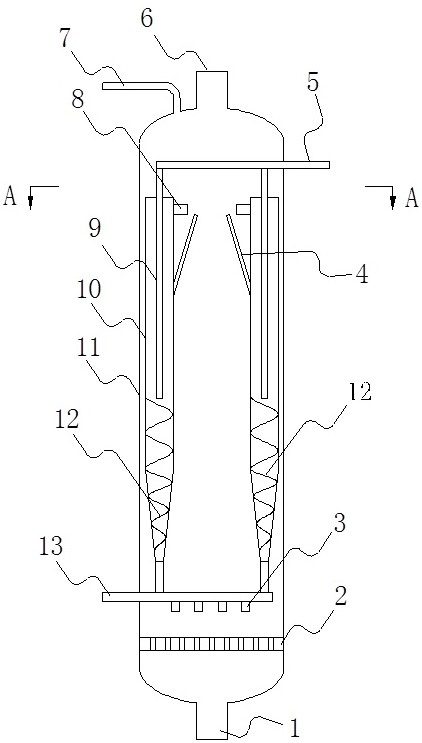

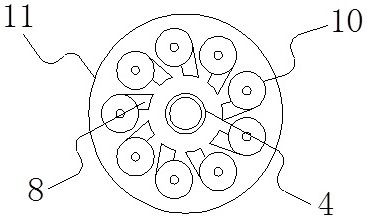

[0070] This embodiment adopts as figure 1 and figure 2 The ebullated bed reactor shown. The ebullated bed reactor is a laboratory reactor with an inner diameter of 3.6cm and a height of 2m. There are 10 cyclone separators inside, and the raw material is vacuum residue.

[0071] The hydrogenation reaction process is as follows:

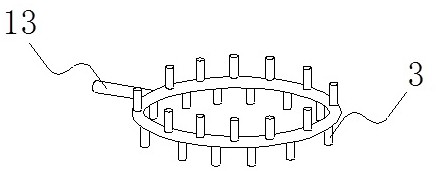

[0072] (1) First mix the vacuum residue with hydrogen, then enter the ebullated bed reactor, and distribute it evenly through the gas-liquid distributor 2 to form a gas-liquid mixture. The gas-liquid mixture drives the catalyst to flow upward and undergo hydrogenation catalytic reaction, decompression The impurity components in the residual oil are reacted and removed under the hydrogen atmosphere; the macromolecular hydrocarbons are continuously decomposed into small molecules.

[0073] (2) After the gas-liquid mixture flows upward and diverts through the conical tube 4, the liquid forms a horizontal separation velocity, and then the liquid drives...

Embodiment 2

[0077] This embodiment adopts as figure 1 and figure 2 The ebullated bed reactor shown. The ebullated bed reactor is an industrial ebullated bed vacuum residue reactor with an inner diameter of 3m and a height of 36.9m. There are 10 cyclone separators inside, and the raw material is vacuum residue.

[0078] The hydrogenation reaction process is as follows:

[0079] (1) The vacuum residue is heated and mixed with hydrogen, and then enters the ebullated bed reactor, and is evenly distributed through the gas-liquid distributor 2 to form a gas-liquid mixture. The gas-liquid mixture drives the catalyst to flow upward and undergo a hydrogenation catalytic reaction. The impurity components in the vacuum residue are reacted and removed in the hydrogen atmosphere; the macromolecular hydrocarbons are continuously decomposed into small molecules.

[0080] (2) After the gas-liquid mixture flows upward and diverts through the conical tube 4, the liquid forms a horizontal separation vel...

Embodiment 3

[0084] The ebullating bed reactor of this embodiment, the raw material is vacuum residual oil, and the difference with embodiment 2 ebullating bed reactor is: the inner diameter of ebullating bed reactor is 4.5m, height 16.4m, the liquid outlet 5 and cylinder 11 There is a circulating pipeline connected between the bottoms, and the circulating oil is pressurized by the circulating pump.

[0085] The hydrogenation reaction process is as follows:

[0086] (1) First mix the vacuum residue with hydrogen, then enter the ebullated bed reactor, and distribute it evenly through the gas-liquid distributor 2 to form a gas-liquid mixture. The gas-liquid mixture drives the catalyst to flow upward and undergo hydrogenation catalytic reaction, decompression The impurity components in the residual oil are reacted and removed under the hydrogen atmosphere; the macromolecular hydrocarbons are continuously decomposed into small molecules.

[0087] (2) After the gas-liquid mixture flows upward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com