Preparation method of a metal-modified three-dimensional carbon network loaded metal-organic framework as a cathode material for lithium/sodium-sulfur batteries

A sodium-sulfur battery and metal modification technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems that hinder the practical application of lithium-sulfur batteries and room temperature sodium-sulfur batteries, reduce active materials, etc., and achieve enhanced conductivity and overall Effects of structural stability, enhanced electrical conductivity and catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

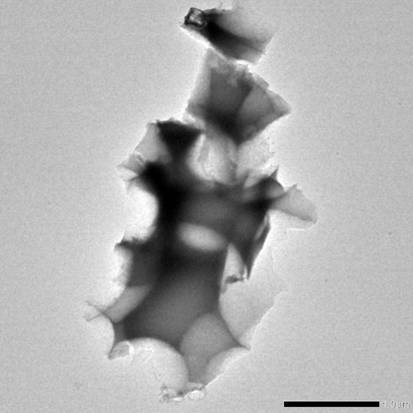

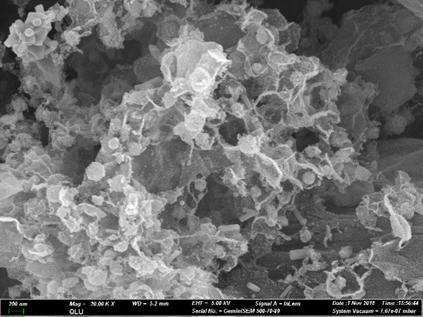

Image

Examples

specific Embodiment example 1

[0022] Specific implementation example 1: take corn bran, corn dregs, cobalt nitrate, dimethylimidazole, and methanol as raw materials. First select about 3g of corn husks, then wash them and add them to 100 mL of 0.1 mol / L cobalt nitrate solution, stir in a water bath at 80°C for 24 hours, filter the product briefly and then dry it at 80°C overnight, and then put the dried product in an air atmosphere at 300°C Incubate for 2 h, mix the obtained product with KOH at a mass ratio of 1:1, add a small amount of distilled water and stir for 24 h, then centrifuge, wash with dilute hydrochloric acid, the concentration of hydrochloric acid is 1 mol / L, dry, and dry the product at 700 °C Calcined for 3 h, weighed 0.5 g of the calcined product and added to 100 mL of methanol solution containing 3.7 g of dimethylimidazole, stirred for 30 min, then poured into 50 mL of methanol solution containing 0.7 g of cobalt nitrate, and continued to stir for 24 h. Afterwards, it was centrifuged and d...

specific Embodiment example 2

[0023] Specific implementation example 2: take corn bran, corn dregs, cobalt nitrate, zinc nitrate, dimethylimidazole, and methanol as raw materials. First select about 3g of corn dregs, then wash them and add them to 100 mL of 0.1mol / L cobalt nitrate solution, stir in a water bath at 80°C for 36 hours, filter the product briefly and then dry it at 80°C overnight, then place the dried product in an air atmosphere at 350°C Keep warm for 2 hours, mix the obtained product with KOH at a mass ratio of 1:4, add a small amount of distilled water and stir for 24 hours, then centrifuge, wash with dilute hydrochloric acid, the concentration of hydrochloric acid is 1 mol / L, dry, and dry the product at 800 ° C Calcined for 3 h, weighed 0.5 g of the calcined product and added to 100 mL of methanol solution containing 3.7 g of dimethylimidazole, stirred for 30 min, then poured into 50 mL of methanol solution containing 0.8 g of zinc nitrate, and continued to stir for 24 h , and then centrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com