Hydrothermal large-cavity high-temperature high-pressure experimental device and experimental method

A high-temperature, high-pressure, experimental device technology, applied to pressure vessels used in chemical processes, etc., can solve the problems of difficult sample chamber volume, inability to adapt, and difficult measurement of solid substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

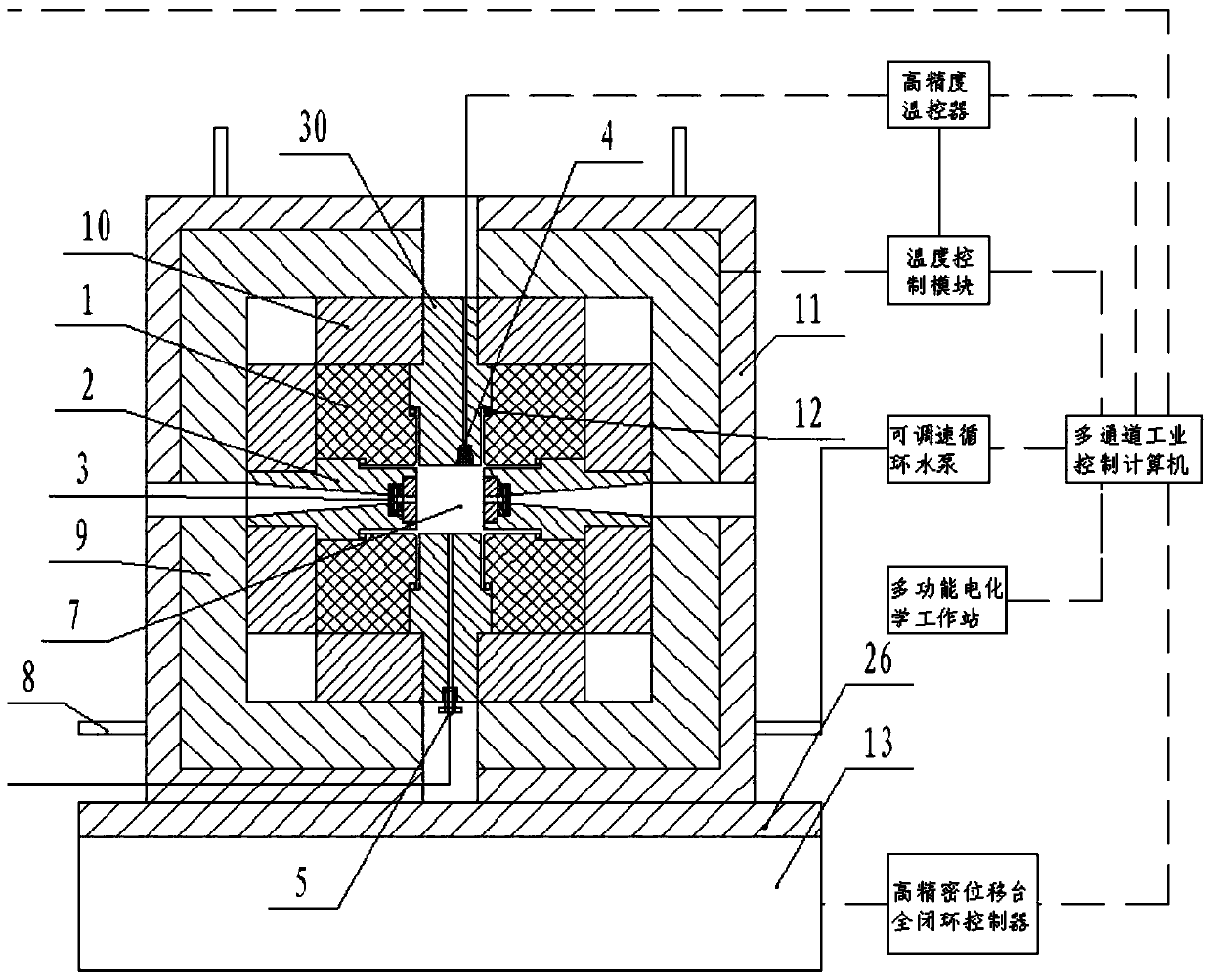

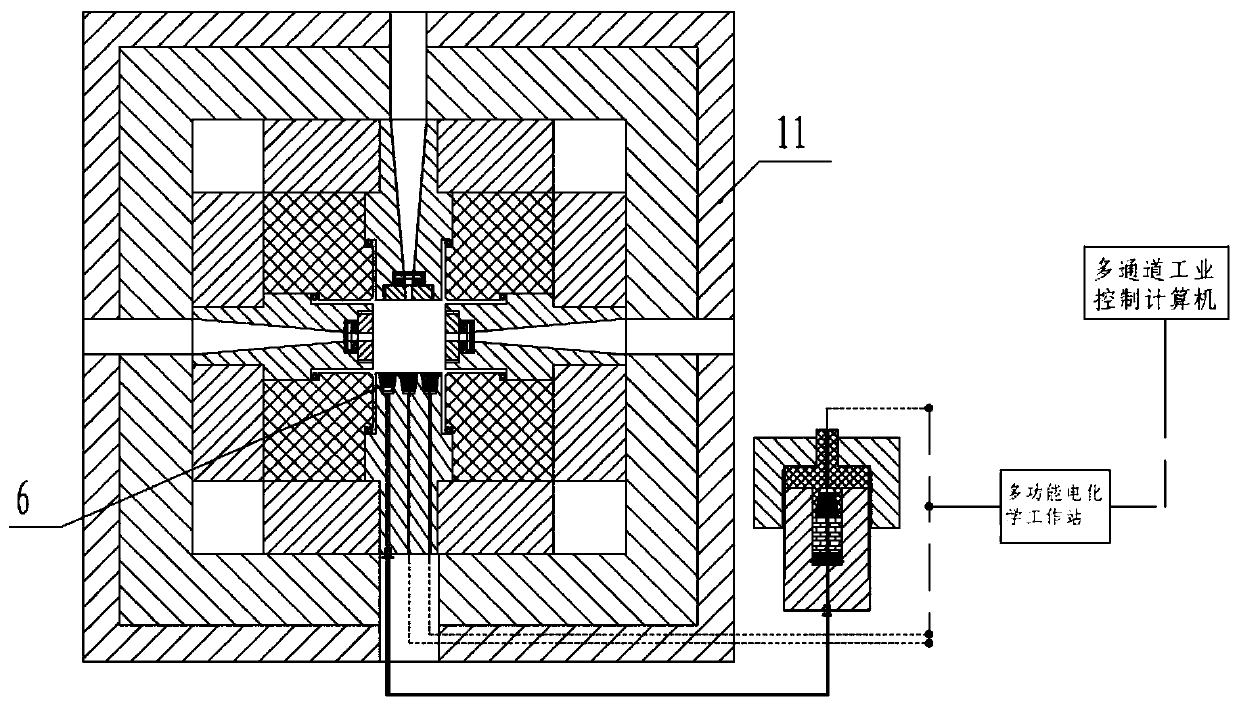

[0063] Embodiment 1: as Figure 1-Figure 12 As shown, a hydrothermal large-cavity high-temperature and high-pressure experimental device includes a kettle body 1 and a kettle plug 2. The kettle body 1 has a hexagonal structure and is made of a high-temperature nickel-based alloy, which is directly processed on a high-temperature nickel-based alloy monolith. , one-time molding, the interior is a sample cavity structure, and the six sides are respectively connected with six detachable and sealed plugs 2. The plugs are made of high-temperature nickel-based alloys. The appearance and size of the six plugs are the same. Optical windows 3 are arranged in the kettle plugs 2, a measurement sensor is installed at the inner end of the remaining one of the kettle plugs in the horizontal direction, a thermocouple 4 is arranged on the kettle plug 2 at the upper end of the kettle body 1, and a thermocouple 4 is installed on the kettle plug 2 at the lower end of the kettle body 1. There is a...

Embodiment 2

[0076] Embodiment 2: an experimental method of a hydrothermal large cavity high temperature and high pressure experimental device, the method comprises the following steps:

[0077] (1) Preliminarily calculate the thickness of the solution to be tested based on the concentration of the solution, the intensity of the light source, and the detection limit information of the substance to be tested, and then select the required length of the optical kettle stopper, and select the corresponding optical window material according to the purpose of the experiment, and Install the optical window on the optical still plug;

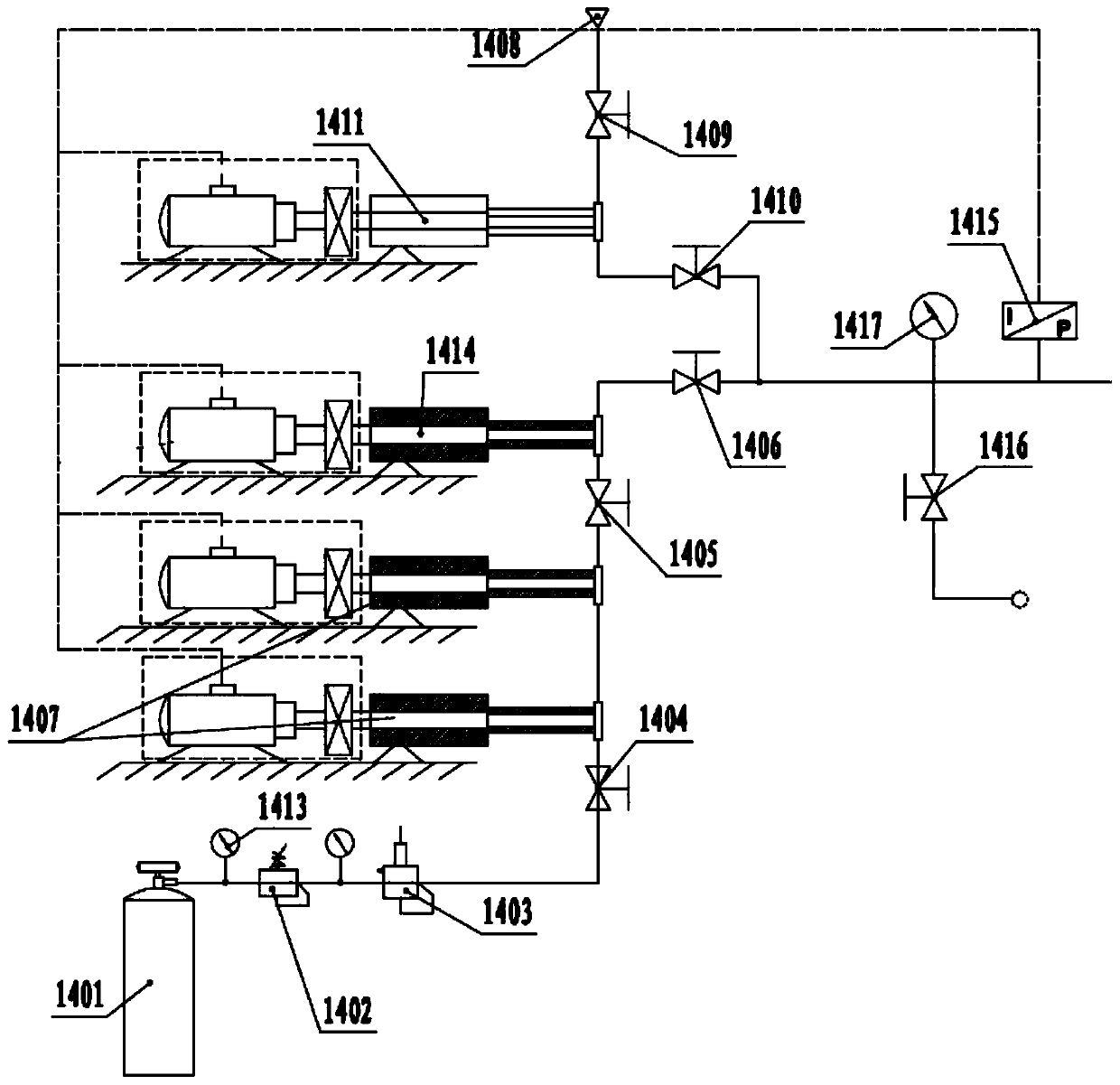

[0078] (2) According to the temperature, pressure, internal volume of the pressure vessel, and the saturated vapor pressure parameters of the aqueous solution at the temperature to be tested, measure the set amount of experimental solution and load the sample. The kettle plug is installed and sealed well, and the confining pressure control system is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com