Production method of superhydrophobic antifog glass

An anti-fog glass and super-hydrophobic technology, applied in the field of materials, can solve the problems of adsorption of dust and other impurities, and achieve the effect of enhanced hydrophobicity, improved dispersibility, and increased contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

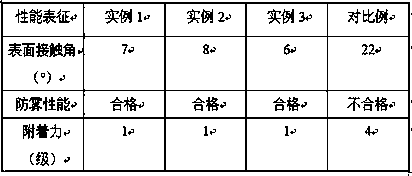

Examples

example 1

[0037] In terms of parts by weight, weigh 15 parts of cyclohexane, 0.1 part of ethylenediamine, 20 parts of tetraethyl orthosilicate, and 150 parts of deionized water, add cyclohexane into deionized water, and set the Stir at a speed of 200r / min for 5min, keep warm to obtain a cyclohexane solution, add ethylenediamine and ethyl orthosilicate to the cyclohexane solution, stir at 300r / min for 10min in a water bath at 50°C, and add dropwise a mass fraction of 1% hydrochloric acid to adjust the pH to 4, react at a constant temperature for 22 hours to obtain a gel, place the gel at 80°C for 22 hours in a vacuum, grind it to obtain nano-silica particles with a particle size of 20nm, and then weigh them in parts by weight 5 parts of hexamethyldisilazane, 20 parts of n-hexane, 10 parts of nano-silica particles, add hexamethyldisilazane into n-hexane, stir at 150r / min for 10min at room temperature to obtain hexamethyldisilazane The n-hexane solution of disilazane, adding nano-silica pa...

example 2

[0039] In parts by weight, weigh 17 parts of cyclohexane, 0.2 parts of ethylenediamine, 23 parts of tetraethyl orthosilicate, and 175 parts of deionized water, add cyclohexane into deionized water, and set Stir at a speed of 225r / min for 7min, keep warm to obtain a cyclohexane solution, add ethylenediamine and ethyl orthosilicate to the cyclohexane solution, stir at 350r / min for 13min in a water bath at 55°C, and add dropwise a mass fraction of 1% hydrochloric acid to adjust the pH to 4.5, and react at a constant temperature for 23 hours to obtain a gel. The gel was vacuum-dried at 85°C for 23 hours, and ground to obtain nano-silica particles with a particle size of 25nm, which were weighed in parts by weight 7 parts of hexamethyldisilazane, 25 parts of n-hexane, 15 parts of nano-silica particles, hexamethyldisilazane was added to n-hexane, and stirred at 175r / min for 13min at room temperature to obtain hexamethyldisilazane The n-hexane solution of disilazane, add nano-silica ...

example 3

[0041] In parts by weight, weigh 20 parts of cyclohexane, 0.3 parts of ethylenediamine, 25 parts of tetraethyl orthosilicate, and 200 parts of deionized water, add cyclohexane into deionized water, and put Stir at a speed of 250r / min for 10min, keep warm to obtain a cyclohexane solution, add ethylenediamine and ethyl orthosilicate to the cyclohexane solution, stir at 400r / min for 15min in a water bath at 60°C, and add dropwise a mass fraction of 1% hydrochloric acid to adjust the pH to 5, react at a constant temperature for 24 hours to obtain a gel, place the gel at 90°C for 24 hours in a vacuum, and grind to obtain nano-silica particles with a particle size of 30nm, which are then weighed in parts by weight 10 parts of hexamethyldisilazane, 30 parts of n-hexane, 20 parts of nano-silica particles, hexamethyldisilazane was added to n-hexane, and stirred at 200r / min for 15min at room temperature to obtain hexamethyldisilazane The n-hexane solution of disilazane, adding nano-sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com