Porous silicon-based ceramic core suitable for double-wall blades and preparation method of core

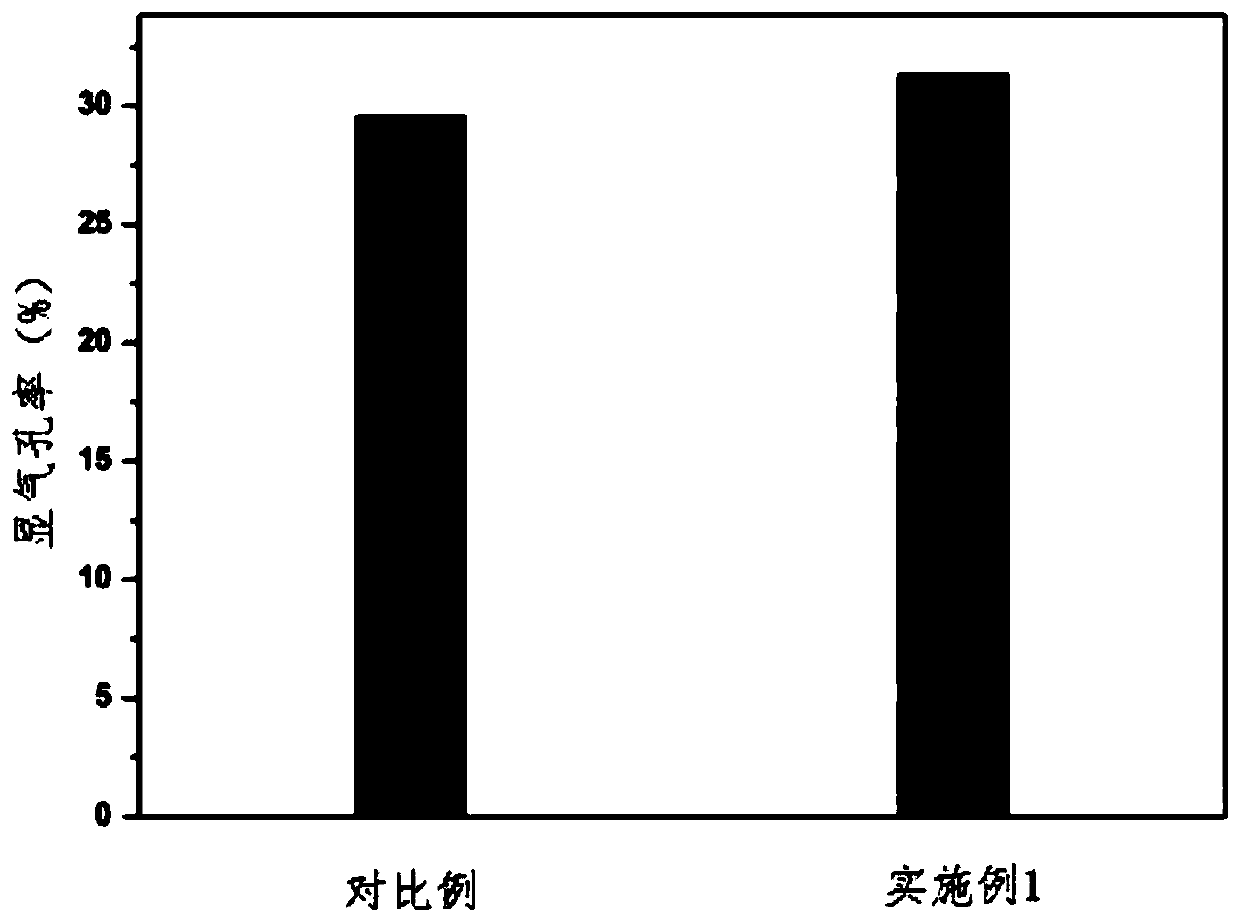

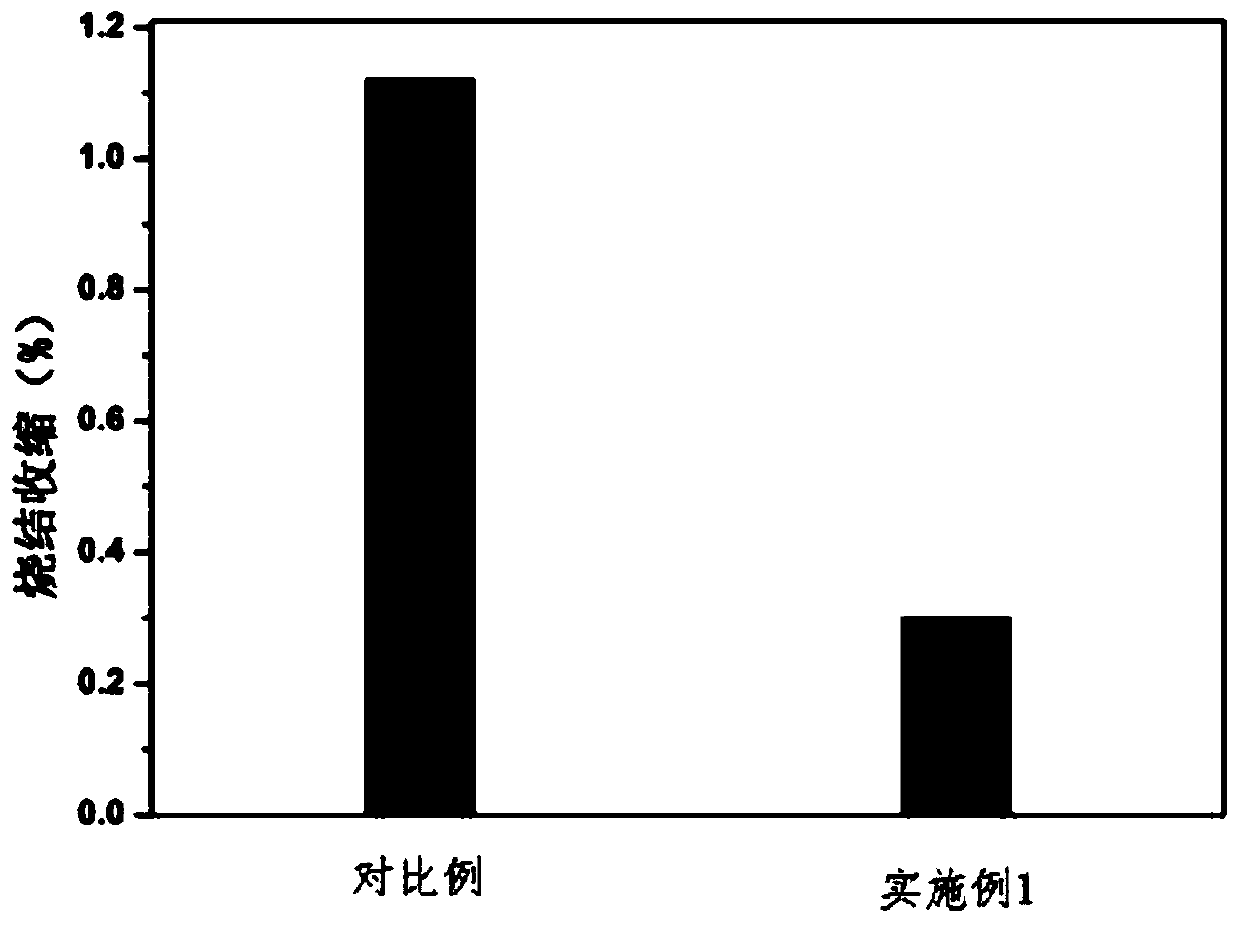

A porous silicon-based, ceramic core technology, applied in cores, casting molding equipment, casting molds, etc., can solve the problems of unqualified blade quality, core shrinkage deformation, complex structure, etc., and achieve short production time and high molding rate The effect of high and high apparent porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

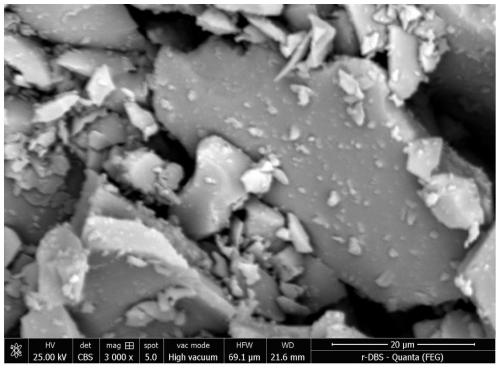

Image

Examples

preparation example Construction

[0041] The present invention provides a method for preparing the porous silicon-based ceramic core described in the above technical solution, comprising the following steps:

[0042] (1) heat preservation after mixing quartz glass powder, fused mullite powder and zirconium silicate powder, obtain ceramic powder;

[0043] (2) thermally mixing the ceramic powder with a plasticizer to obtain a prefabricated material;

[0044] (3) Sequentially pressing and shaping the prefabricated material to obtain a biscuit;

[0045] (4) Sintering and strengthening treatment are performed on the green body in sequence to obtain a porous silicon-based ceramic core suitable for double-wall blades.

[0046] In the invention, the quartz glass powder, the fused mullite powder and the zirconium silicate powder are mixed and then kept warm to obtain the ceramic powder. In the present invention, the mixing is preferably carried out in a ball mill; the heat preservation is preferably carried out in an...

Embodiment 1

[0062] (1) Prepare ceramic powder: Stir 80 parts of quartz glass powder, 10 parts of mullite powder, and 10 parts of zirconium silicate powder in parts by mass, then put them into an incubator and keep them warm for 10 hours at a temperature of 120°C. , to obtain ceramic powder; the quartz glass powder is composed of quartz glass powder with a particle size of (0,10) μm, [10,30) μm, [30,50) μm and [50,95] μm in mass ratio 20.32: 36.95: 29.61: 13.12, the mullite powder is mixed with 200 mesh and 325 mesh mullite powder with a mass ratio of 1:1, and the zirconium silicate powder is formed with a mass ratio of 1: 1. It is made by mixing 200 mesh and 325 mesh zirconium silicate powder.

[0063] (2) Preparation of prefabricated materials: Add the ceramic powder obtained in step (1) to the plasticizer (ceramic casting wax) at a mass ratio of 100:16.5 at a temperature of 90°C and stir at a stirring speed of 90r / min , get the prefabricated material;

[0064] (3) Pressing and orthope...

Embodiment 2

[0078] (1) Prepare ceramic powder: Stir 75 parts of quartz glass powder, 10 parts of mullite powder, and 15 parts of zirconium silicate powder in parts by mass, and then put them in an incubator and keep them warm for 10 hours at a temperature of 120°C. , to obtain ceramic powder; the quartz glass powder is composed of quartz glass powder with a particle size of (0,10) μm, [10,30) μm, [30,50) μm and [50,95] μm in mass ratio 25.43:39.14:30.84:18.12 mixed, the mullite powder is mixed with 200 mesh and 325 mesh mullite powder with a mass ratio of 2:1, and the zirconium silicate powder is formed with a mass ratio of 1.5: 1. It is made by mixing 200 mesh and 325 mesh zirconium silicate powder.

[0079] (2) Preparation of prefabricated material: Add the ceramic powder obtained in step (1) to the plasticizer (ceramic casting wax) at a mass ratio of 100:17.6 at a temperature of 90°C and stir at a stirring speed of 90r / min , get the prefabricated material;

[0080] (3) Pressing and o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com