Low-pressure vacuum carburizing heat treatment method for 16Cr3NiWMoVNbE

A heat treatment method and technology of the treatment method, applied in the field of low-pressure vacuum carburizing heat treatment of 16Cr3NiWMoVNbE materials, can solve the problems of carbide size, poor distribution uniformity, long carburizing time, and large energy consumption in the carburized layer, and achieve simple composition and high energy consumption. Fatigue performance, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

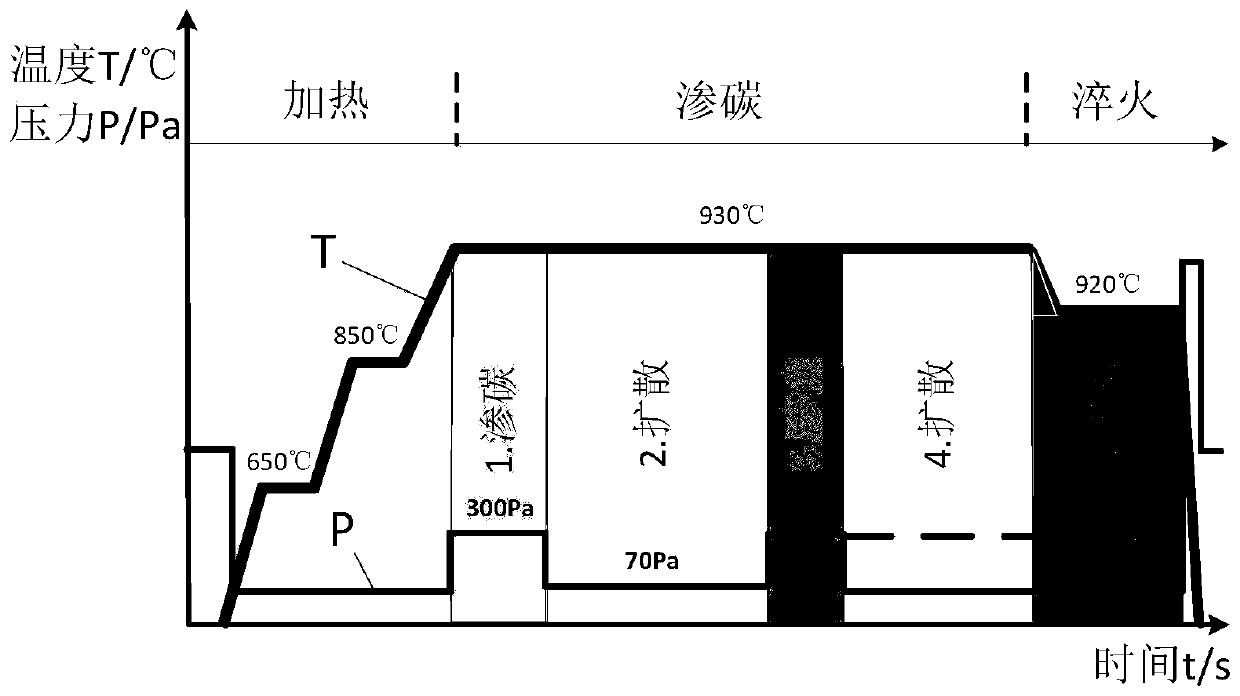

[0051] The steps of the vacuum carburizing heat treatment process example are as follows: the schematic diagram is as follows figure 1 As shown, the experimental steel composition is C 0.17%, Si 0.65%, Mn 0.58%, Cr 2.6%, Ni 1.1%, W 1.2%, Mo 0.45%, V 0.42%, Nb 0.16%, P≤0.010%, S≤ 0.010%, Cu 0.01%, and the balance is iron. In this embodiment, the preset depth of the seepage layer is 1.0mm.

[0052] (1) High-temperature pretreatment: high-temperature tempering process is adopted, that is, the 16Cr3NiWMoVNbE material is tempered at 650 °C for 2 hours.

[0053] (2) Carburizing: Carburizing is carried out in a double-chamber low-pressure vacuum carburizing furnace. The carburizing process includes three stages of feeding and vacuuming, stage heating, and pulse carburizing (strong carburizing and diffusion).

[0054] ① Vacuuming: Clean the surface of the 16Cr3NiWMoVNbE material to remove oil stains, and vacuumize the furnace after feeding, with an absolute pressure of 20Pa.

[005...

Embodiment 2

[0062] The composition of the experimental steel is the same as in Example 1, and the preset depth of the infiltrated layer is 0.8 mm. The steps of the vacuum carburizing heat treatment process example are as follows:

[0063] (1) High temperature pretreatment: adopt high temperature tempering process, temper 16Cr3NiWMoVNbE material at 680°C for 3h.

[0064] (2) Carburizing: Carburizing is carried out in a double-chamber low-pressure vacuum carburizing furnace, as follows:

[0065] ① Vacuuming: Clean the surface of the 16Cr3NiWMoVNbE material to remove oil stains, and vacuumize the furnace after feeding, with an absolute pressure of 25Pa.

[0066] ②Stage heating: the 16Cr3NiWMoVNbE material is austenitized in a low-pressure vacuum carburizing furnace, the carburizing temperature is 950°C, the heating process is a three-stage heating process, and the heating rate is 10°C / min, respectively at 600°C and 800°C and 950°C for 1 hour each.

[0067] ③Pulse carburizing: Fill the fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heart hardness | aaaaa | aaaaa |

| Hardness value | aaaaa | aaaaa |

| Heart hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com