Novel composite gas explosion suppressant

An explosion suppressor and gas technology, applied in safety devices, fire protection equipment, mining equipment and other directions, can solve the problems of complex modification process of red mud powder, unable to meet the needs of industrial production, and the effect of explosion suppression is not obvious. The effect of explosion suppression performance, developed voids and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

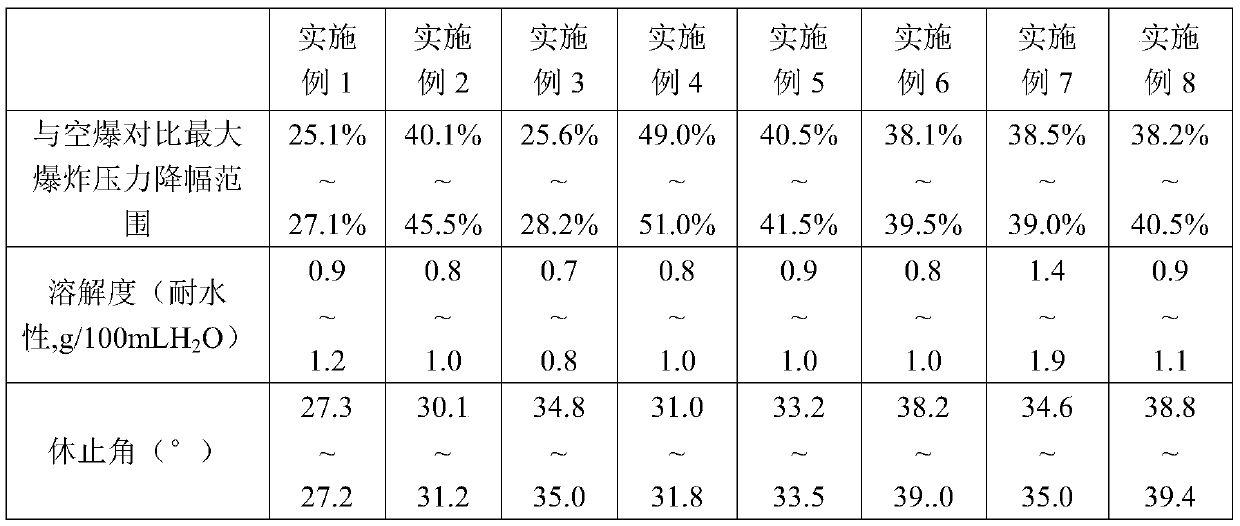

Examples

Embodiment 1

[0023] The raw materials aluminum hydroxide, kaolin powder and ammonium polyphosphate are mixed according to the mass ratio of 2:1:5. All the above-mentioned ingredients are pulverized into a uniform powder and mixed uniformly in a high-speed mixer according to the above-mentioned ratio, and the mixed product is dried to obtain the finished product.

Embodiment 2

[0025] The preparation method is the same as that of Example 1, except that the mass ratio of aluminum hydroxide, kaolin powder and ammonium polyphosphate is 2:2:5.

Embodiment 3

[0027] The preparation method is the same as that of Example 1, except that the mass ratio of aluminum hydroxide, kaolin powder and ammonium polyphosphate is 2:3:5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com