Biomass power generation method

A biomass power generation and biomass technology, which is applied in combustion methods, machines/engines, hot gas variable capacity engine devices, etc. Thermal efficiency, the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

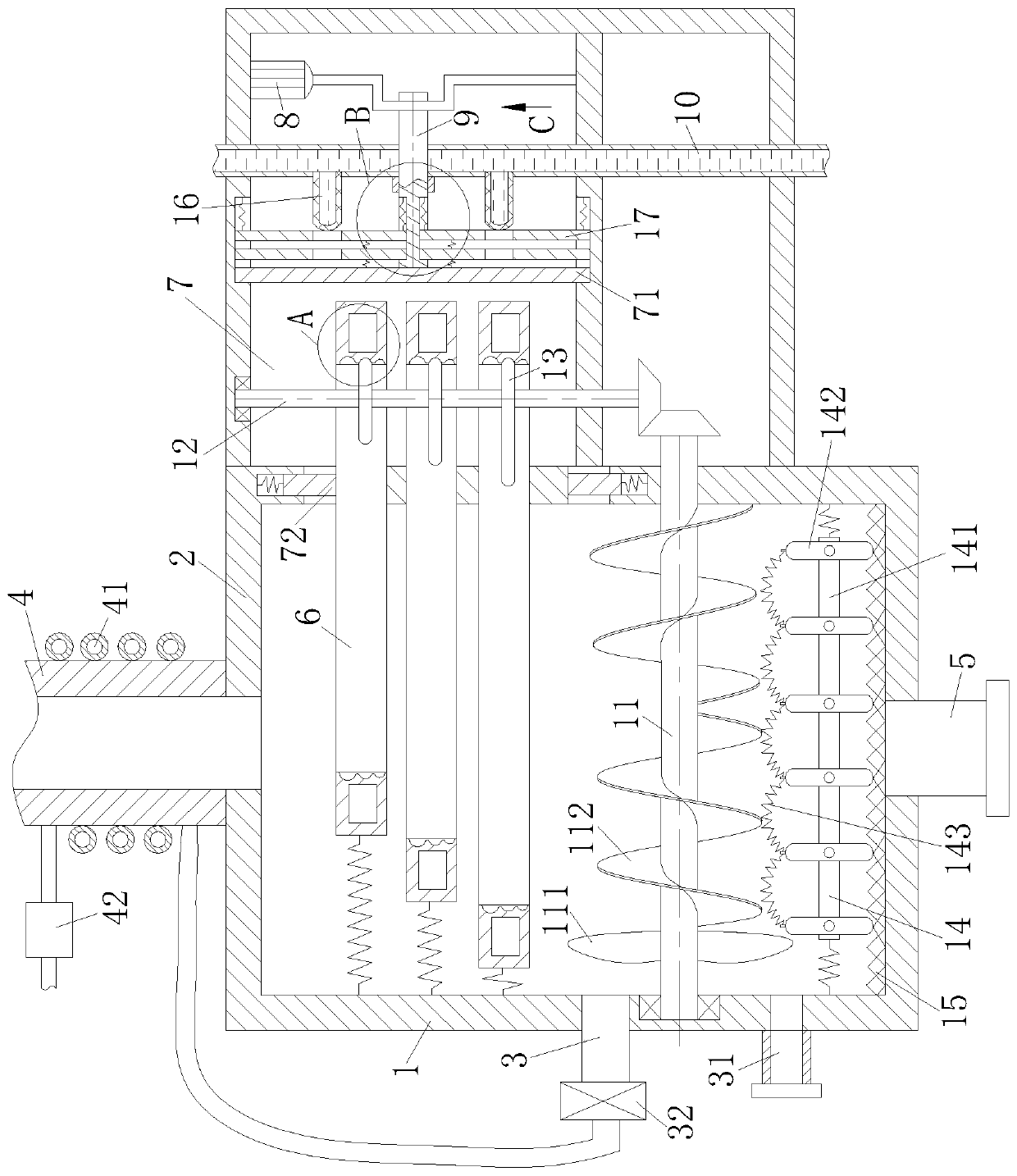

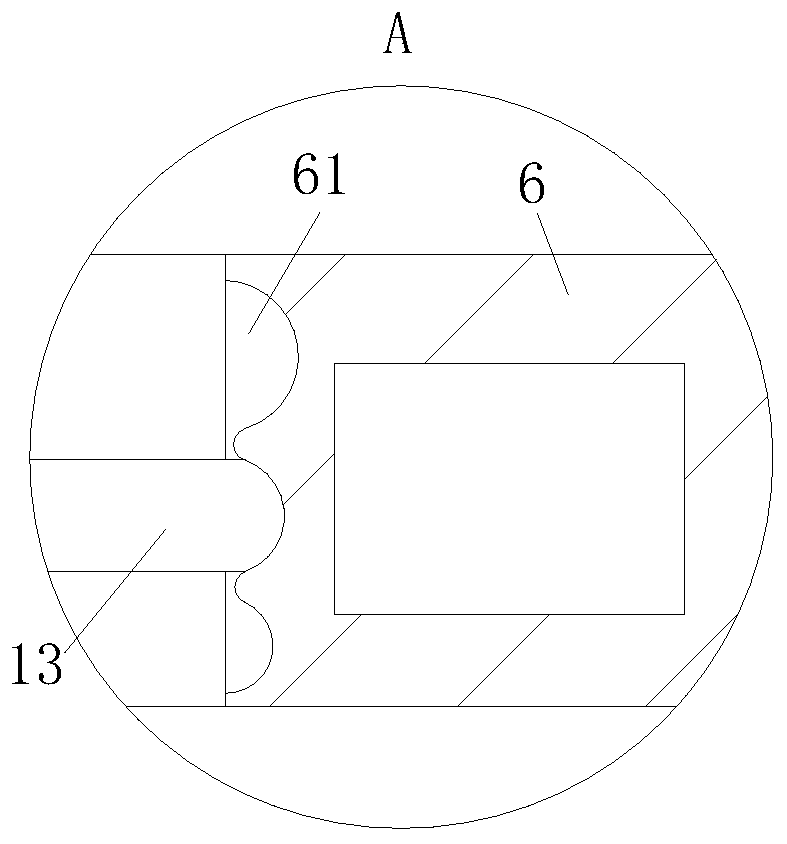

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

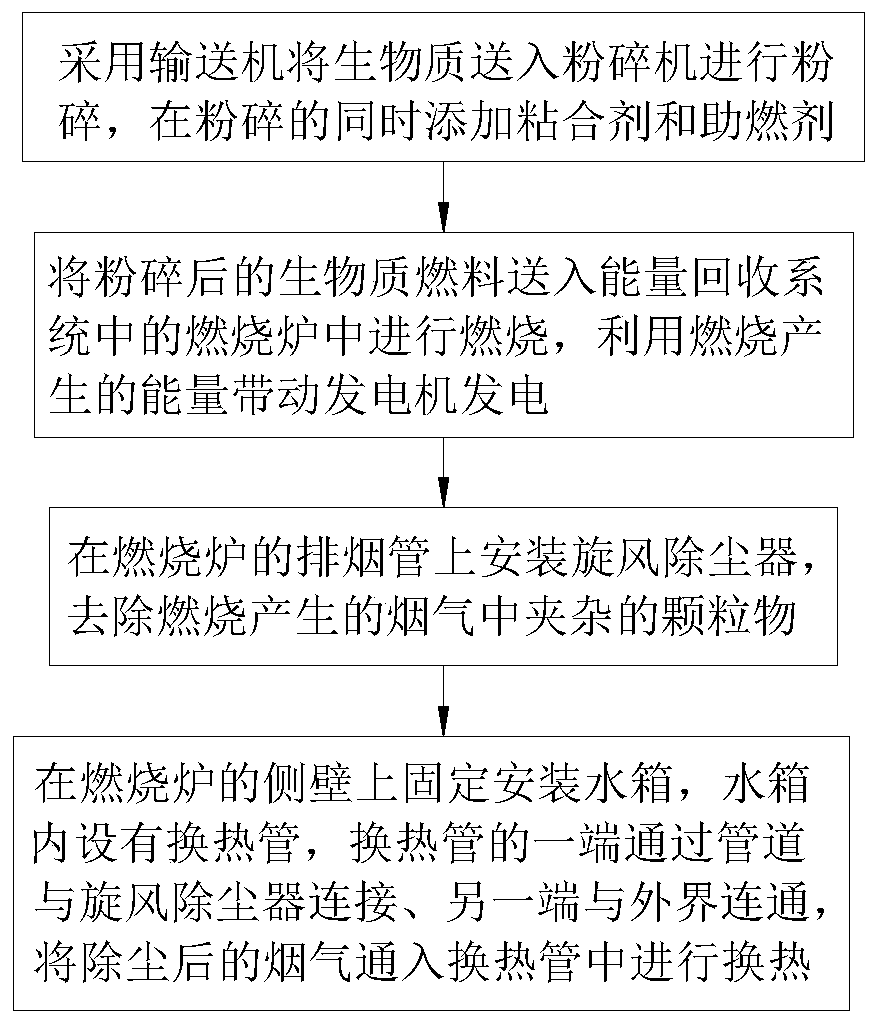

[0030] Such as Figure 1 to Figure 6Shown, a kind of biomass power generation method of the present invention, the method steps are as follows:

[0031] S1: Use a conveyor to send the biomass into the pulverizer for pulverization, and add binders and combustion aids while pulverizing;

[0032] S2: Send the pulverized biomass fuel in S1 to the combustion furnace in the energy recovery system for combustion, and use the energy generated by combustion to drive the generator to generate electricity; the biomass fuel can be effectively used to achieve rapid power generation;

[0033] S3: Install a cyclone dust collector on the exhaust pipe of the combustion furnace in S2 to remove the particulate matter mixed in the flue gas generated by combustion; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com