Preparation method of enhanced polyvinylidene fluoride lithium battery conductive adhesive

A polyvinylidene fluoride and conductive binder technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of lithium-ion battery discharge capacity decline, battery system safety hazards, active material shedding, etc. Electrochemical properties, enhanced interfacial stability, and improved bonding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of enhanced binder: put the silane coupling agent mixture, PVDF, and NMP in a round-bottomed flask at a mass ratio of 1:5:50, and magnetically stir for 1 hour to obtain the enhanced polymer modified by the silane coupling agent. Vinylidene fluoride binder. Among them, the mass ratio of KH550 and KH570 is 0.28:0.72.

[0021] Preparation of positive electrode homogeneous slurry: Mix the positive active material commercial ternary material NCM523, conductive carbon, reinforced polyvinylidene fluoride binder, and NMP according to the mass ratio of 17:2:10:80, and perform ball milling for 1.5h. homogeneously to obtain positive electrode slurry.

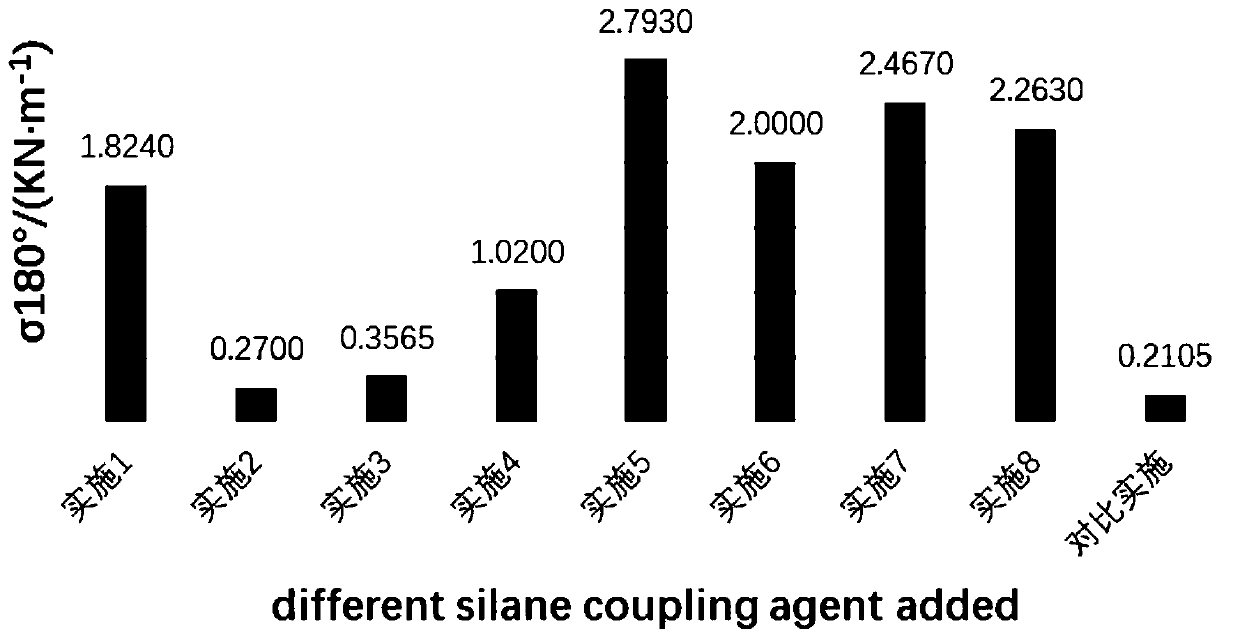

[0022] Test sample preparation: Coat the positive electrode slurry on an aluminum foil with a thickness of 15um, dry it, and prepare samples according to the sample preparation requirements in "GB / T2790-1995 Adhesive 180° Peel Strength Test Method Flexible Materials Versus Rigid Materials" test, the result of which is ...

Embodiment 2

[0024] Preparation of reinforced binder: put silane coupling agent mixture:PVDF:NMP in a round bottom flask according to the mass ratio of 2:5:40, and magnetically stir for 3h to obtain the reinforced polymer modified by silane coupling agent. Vinylidene fluoride binder. Among them, the mass ratio of KH560, KH550 and KH570 is 0.4:0.2:0.4.

[0025] Preparation of homogeneous positive electrode slurry: mix the positive active material commercial ternary material NCM523, conductive carbon, reinforced polyvinylidene fluoride binder, and NMP according to the mass ratio of 17:2:10:80, and perform ball milling for 3 hours to mix , to obtain positive electrode slurry.

[0026] Test sample preparation: Coat the positive electrode slurry on an aluminum foil with a thickness of 15um, dry it, and prepare samples according to the sample preparation requirements in "GB / T2790-1995 Adhesive 180° Peel Strength Test Method Flexible Materials Versus Rigid Materials" test, the result of which i...

Embodiment 3

[0028] Preparation of reinforced binder: put the silane coupling agent mixture: PVDF: NMP in a round bottom flask according to the mass ratio of 2:5:50, and magnetically stir for 2 hours to obtain the reinforced polymer modified by silane coupling agent. Vinylidene fluoride binder. The silane coupling agent mixture is made by mixing KH560, KH550, KH570, and KH792 in a mass ratio of 0.35:0.25:0.1:0.3.

[0029] Preparation of homogeneous positive electrode slurry: Mix positive active material commercial ternary material NCM523, conductive carbon, reinforced polyvinylidene fluoride binder, and NMP at a mass ratio of 17:2:10:80, and perform ball milling for 2 hours to mix , to obtain positive electrode slurry.

[0030] Test sample preparation: Coat the positive electrode slurry on an aluminum foil with a thickness of 15um, dry it, and prepare samples according to the sample preparation requirements in "GB / T2790-1995 Adhesive 180° Peel Strength Test Method Flexible Materials Versu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com