Polymer fire-proof and moisture-proof sealing agent and its preparation method and application

A technology of blocking agent and polymer, applied in the field of polymer fire-proof and moisture-proof blocking agent and its preparation, can solve the problems of poor fire-proof and moisture-proof effect, poor leveling effect, difficulty in secondary construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

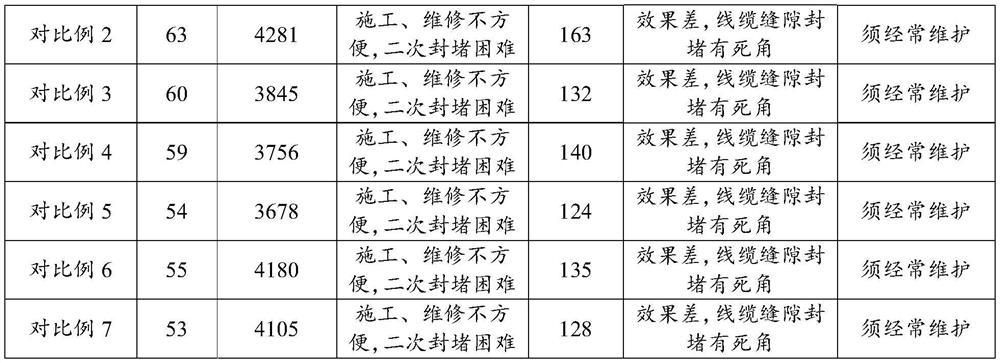

Examples

preparation example Construction

[0069] According to the second aspect of the present invention, the present invention provides a kind of preparation method of macromolecule fire-proof and moisture-proof sealing agent, comprises the following steps:

[0070] (a) mixing vinyl silicone oil, optional flame retardant, optional ceramic powder and the first silane coupling agent and stirring at a high speed to form a base;

[0071] (b) Take part of the base material and add platinum complex and stir evenly to make Agent A;

[0072] (c) Take the remaining base material and add hydrogen-containing silicone oil, the second silane coupling agent, an optional reaction rate control agent, an optional heat-resistant agent and an optional fire-resistant agent, and stir evenly to make agent B;

[0073] (d) Mix agent A and agent B uniformly to obtain a polymer fire-proof and moisture-proof sealing agent.

[0074] The preparation method of the polymer fire-proof and moisture-proof plugging agent provided by the invention has...

Embodiment 1

[0082]This embodiment provides a polymer fire-proof and moisture-proof plugging agent, including the following raw materials in parts by mass: 80 parts of vinyl silicone oil, 0.5 parts of vinyl trimethoxysilane, 0.3 parts of triethoxyvinyl silane, 5 parts of platinum complex, 1 part of hydrogen-containing silicone oil, 50 parts of decabromodiphenylethane, 10 parts of ceramic powder, 0.5 parts of acetylene cyclohexanol, 1 part of cerium oxide and 30 parts of zirconium oxide.

Embodiment 2

[0084] This embodiment provides a polymer fire-proof and moisture-proof plugging agent, including the following raw materials in parts by mass: 120 parts of vinyl silicone oil, 0.3 parts of vinyl trimethoxysilane, 1.2 parts of triethoxyvinyl silane, 2 parts of platinum complex, 3 parts of hydrogen-containing silicone oil, 20 parts of decabromodiphenylethane, 20 parts of ceramic powder, 0.1 part of acetylene cyclohexanol, 3 parts of cerium oxide and 10 parts of zirconium oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com