Environment-friendly durable chalk material

A durable, chalky technology, applied in applications, pencil leads, household utensils, etc., can solve problems such as endangering health, and achieve the effects of less environmental pollution, convenient use, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

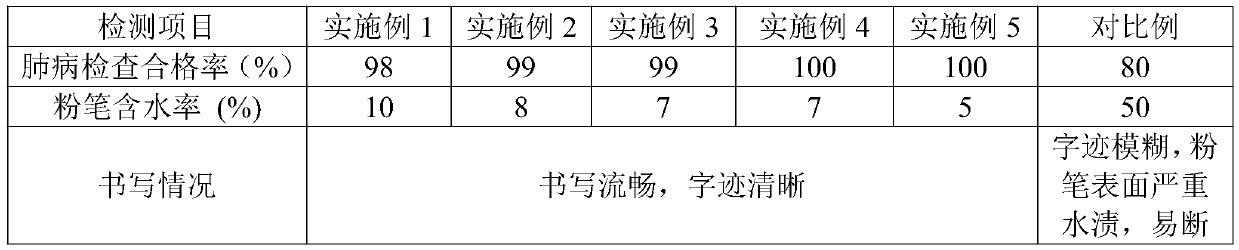

Examples

Embodiment 1

[0032] An environmentally friendly and durable chalk material, which is made of the following raw materials in parts by weight: 25 parts of titanium dioxide, 5 parts of attapulgite, 1 part of negative ion powder, 1 part of sepiolite powder, 10 parts of clay, 1 part of Chinese medicine extract, N -1 part of (3-triethoxysilylpropyl) glucamide, 1015 parts of epoxy paraffin modified quaternary ammonium salt, 1 part of sodium methylstearyl taurate, 1 part of witch hazel tannin, 7 parts of oleic acid modified vegetable oil, 1 part of glycerin, and 1 part of ethanol.

[0033] The preparation method of the epoxy paraffin modified quaternary ammonium salt-10 comprises the following steps: adding 10 g of epoxy paraffin wax and 1010 g of quaternary ammonium salt to 100 g of xylene, then adding 3 g of sodium carbonate therein, Stir the reaction for 6 hours, then remove the organic solvent by rotary evaporation, wash the product 3 times with water, then wash 3 times with acetone, and final...

Embodiment 2

[0041] An environmentally friendly and durable chalk material, which is made of the following raw materials in parts by weight: 26 parts of titanium dioxide, 6 parts of attapulgite, 2 parts of negative ion powder, 3 parts of sepiolite powder, 12 parts of clay, 2 parts of Chinese medicine extract, N -1 part of (3-triethoxysilylpropyl) glucamide, 1016 parts of epoxy paraffin modified quaternary ammonium salt, 2 parts of sodium methylstearyl taurate, 3 parts of witch hazel tannin, 8 parts of oleic acid modified vegetable oil, 1 part of glycerin, 2 parts of ethanol.

[0042] The preparation method of described epoxy paraffin modified quaternary ammonium salt-10 comprises the steps of: adding epoxy paraffin 15g, quaternary ammonium salt-1010g in chloroform 110g, then adding potassium carbonate 3.5g wherein, at 87 The reaction was stirred at ℃ for 6.5 hours, and then the organic solvent was removed by rotary evaporation, the product was washed 4 times with water, and then washed 3 t...

Embodiment 3

[0050] An environment-friendly and durable chalk material, which is made of the following raw materials in parts by weight: 28 parts of titanium dioxide, 8 parts of attapulgite, 3 parts of negative ion powder, 4 parts of sepiolite powder, 16 parts of clay, 3 parts of Chinese medicine extract, N -2 parts of (3-triethoxysilylpropyl) glucamide, 1018 parts of epoxy paraffin modified quaternary ammonium salt, 3 parts of sodium methylstearyl taurate, 4 parts of witch hazel tannin, 8 parts of oleic acid modified vegetable oil, 2 parts of glycerin, 3 parts of ethanol.

[0051] The preparation method of the epoxy paraffin modified quaternary ammonium salt-10 comprises the following steps: adding 20 g of epoxy paraffin and quaternary ammonium salt-1010 g to 130 g of petroleum ether, then adding 4 g of sodium hydroxide therein, The reaction was stirred for 7 hours, and then the organic solvent was removed by rotary evaporation, the product was washed 4 times with water, and then washed 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com