Epoxy adhesive and preparation method thereof

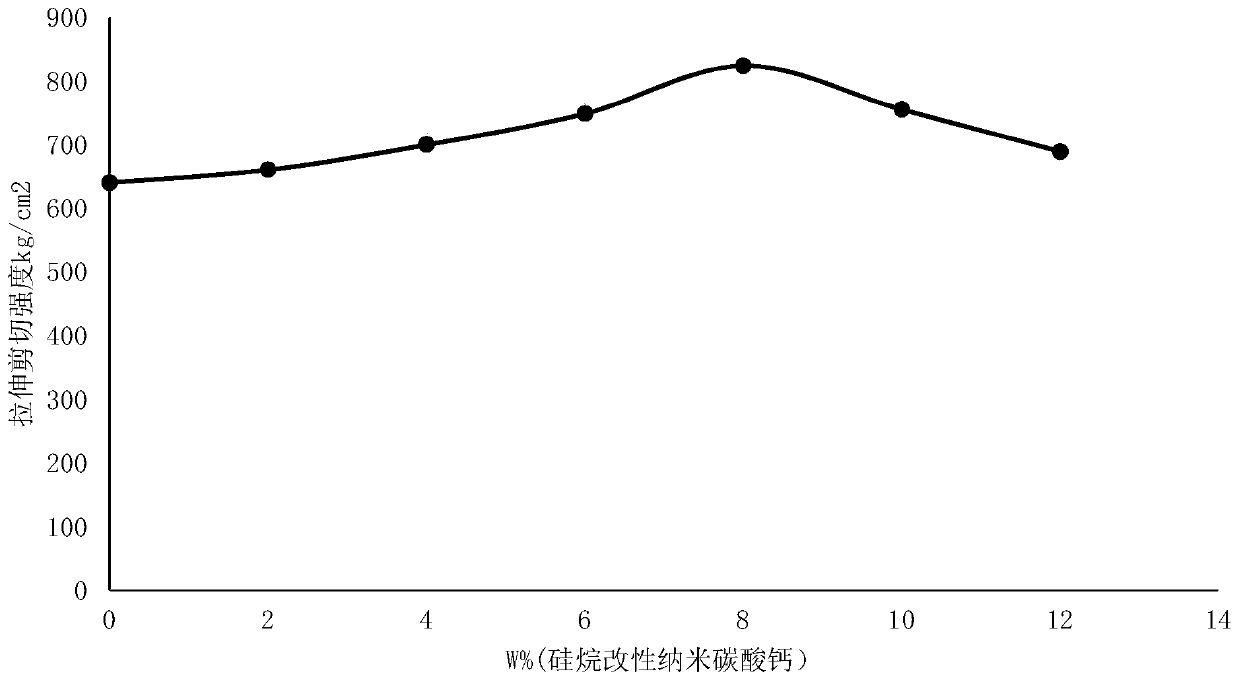

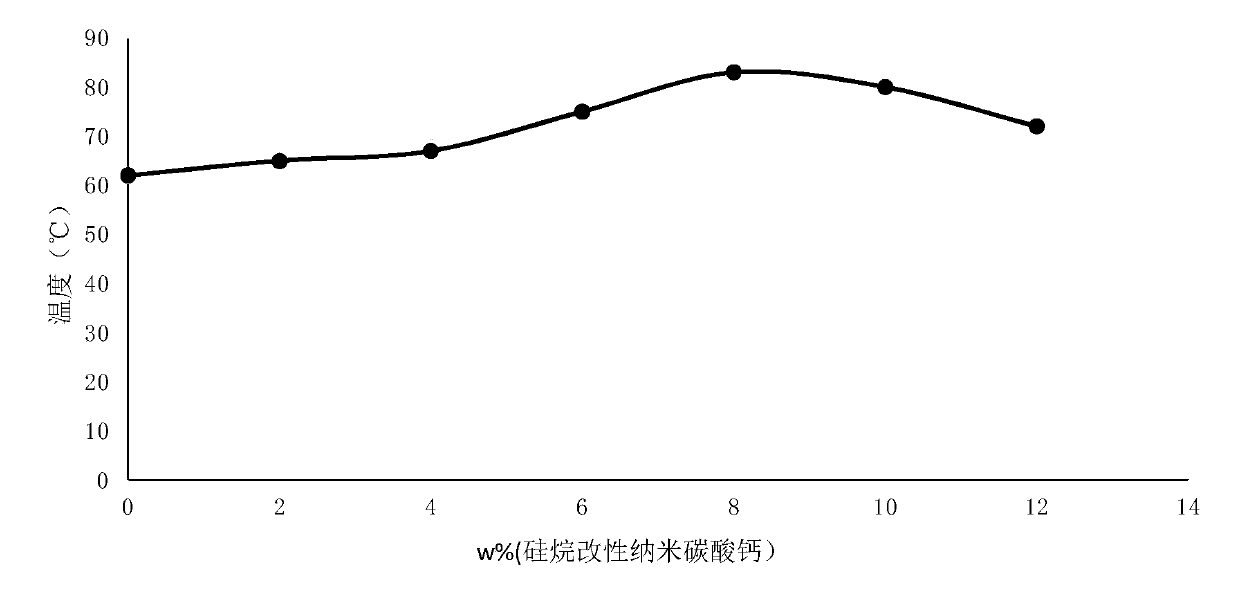

A technology of epoxy adhesive and epoxy resin, which is applied in the direction of epoxy resin glue, adhesive, adhesive additive, etc., can solve the problem of high tensile shear strength and high temperature resistance, which epoxy adhesive does not have, Short storage period and other issues, to achieve the effect of improving tensile shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An epoxy adhesive, including: A glue and B glue,

[0033] Glue A includes the following raw material components in parts by weight: 50 parts of bisphenol A epoxy resin, 25 parts of industrial calcium carbonate, 5 parts of silane-modified nano-calcium carbonate, 3 parts of reactive diluent and 0.1 part of Fumed silica;

[0034] B glue includes the following raw material components in parts by weight: 40 parts of high molecular weight polyamide curing agent, 3 parts of accelerator, 40 parts of industrial calcium carbonate, 5 parts of silane modified nano-calcium carbonate, 3 parts of active diluent agent and 0.1 part of fumed silica.

[0035] The reactive diluent includes one or more of n-butyl glycidyl ether or glycidyl methacrylate.

[0036] The preparation method of above-mentioned epoxy adhesive, wherein,

[0037] The preparation method of A glue comprises the following steps:

[0038] Get bisphenol A type epoxy resin, industrial calcium carbonate, silane-modified...

Embodiment 2

[0042] An epoxy adhesive, including: A glue and B glue,

[0043] Glue A includes the following raw material components in parts by weight: 60 parts of bisphenol A epoxy resin, 30 parts of industrial calcium carbonate, 10 parts of silane-modified nano-calcium carbonate, 2 parts of reactive diluent, 3 parts of non-reactive diluent and 1 part fumed silica;

[0044]B glue includes the following raw material components in parts by weight: 45 parts of high molecular weight polyamide curing agent, 5 parts of accelerator, 45 parts of industrial calcium carbonate, 10 parts of silane-modified nano carbonic acid, 2 parts of reactive diluent , 3 parts of non-reactive diluent and 1 part of fumed silica.

[0045] The reactive diluent includes one or more of n-butyl glycidyl ether or glycidyl methacrylate.

[0046] Inactive diluents include one or more of benzene, toluene, xylene, benzyl alcohol, ketone solvents or ester solvents.

[0047] The preparation method of above-mentioned epoxy a...

Embodiment 3

[0053] An epoxy adhesive, including: A glue and B glue,

[0054] Glue A includes the following raw material components in parts by weight: 52 parts of bisphenol A epoxy resin E-44, 27 parts of industrial calcium carbonate, 8 parts of silane-modified nano-calcium carbonate, 4 parts of benzyl alcohol and 0.8 parts parts of fumed silica;

[0055] B glue includes the following raw material components in parts by weight: 43 parts of high molecular weight polyamide curing agent, 4 parts of accelerator K-54, 42 parts of industrial calcium carbonate, 7 parts of silane modified nano calcium carbonate, 4 parts Benzyl alcohol and 0.7 parts of fumed silica.

[0056] The preparation method of above-mentioned epoxy adhesive, wherein,

[0057] The preparation method of A glue comprises the following steps:

[0058] Take bisphenol A type epoxy resin E-44, industrial calcium carbonate, silane modified nano-calcium carbonate and benzyl alcohol and mix them for the first time (800 rpm, 1.5 ho...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap