A device and method for removing volatile organic compounds in acrylic emulsion

An organic compound and acrylic emulsion technology, which is applied in chemical instruments and methods, separation methods, liquid degassing, etc., can solve problems such as difficulty in device cleaning, human suffocation, performance and stability effects, etc., to reduce production energy consumption and Disposal costs, low VOC content, and continuous operation are safe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

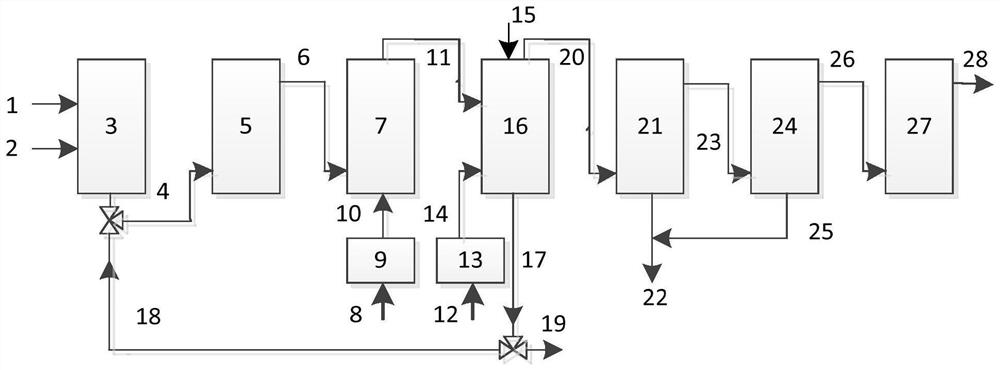

Method used

Image

Examples

Embodiment 1

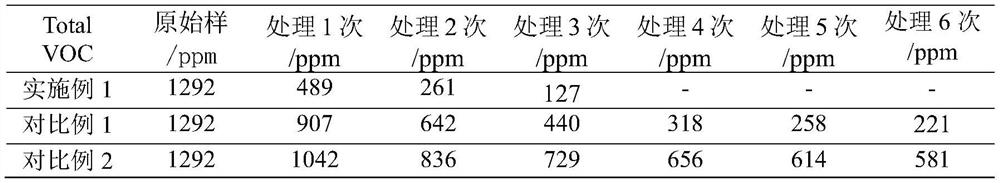

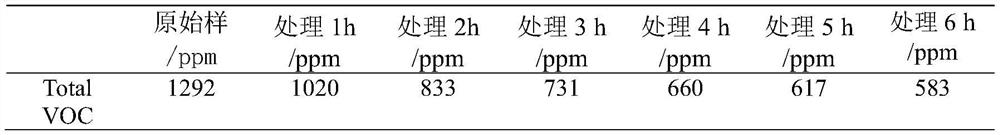

[0092] Test according to the test device created by the present invention.

[0093] Put 50kg of acrylic emulsion into the storage tank with agitation, heat it to 45°C through plate exchange, enter the lower part of the gas-liquid mixer at a flow rate of 60kg / h, and at the same time a group of air (air flow rate of 0.3m 3 / h, 0.1MPa) is heated to 55°C by an air heater and enters the bottom of the gas-liquid mixer, and is fully mixed with the emulsion to form a uniform air-emulsion mixture. The mixture enters the top 1 / 3 of the VOC removal tower, and another group of air ( The air velocity is 3.0m 3 / h, 0.1MPa) is heated by an air heater to 40°C and then enters the bottom of the VOC removal tower. The operating pressure of the VOC removal tower is -20KPa, and the volatile organic compound gas after removal of VOC enters the cooling tower from the extraction line of the VOC removal tower Condensation, a small part of non-condensed volatile organic compounds enters the tail gas a...

Embodiment 2

[0108] Example 2 was performed on a larger scale than Example 1. Pour 8000kg of acrylic emulsion into the storage tank with agitation, heat it to 50°C through plate exchange, enter the lower part of the gas-liquid mixer at a flow rate of 80kg / min, and at the same time, a group of air (air flow rate of 20m3 / h, 0.1MPa) passes through the air heater After heating to 65°C, it enters the bottom of the gas-liquid mixer and fully mixes with the emulsion to form a uniform air-emulsion mixture. The mixture enters the top 1 / 3 of the VOC tower, and another set of air (air flow rate is 100m3 / h, 0.1MPa) After being heated by an air heater to 50°C, it enters the bottom of the VOC removal tower, and the pure water injector at the top of the VOC removal tower sprays pure water for 5 minutes after an interval of 5 minutes (the flow rate of pure water is 10kg / min) to supplement solid content and clean the tower wall , the nozzle on the top of the VOC removal tower is sprayed obliquely downward ...

Embodiment 3

[0112] Example 3 was performed on a larger scale than Example 1. Pour 6000kg of acrylic emulsion into the storage tank with agitation, heat it to 45°C through plate exchange, enter the lower part of the gas-liquid mixer at a flow rate of 100kg / min, and at the same time a group of air (air flow rate of 15m 3 / h, 0.1MPa) is heated to 55°C by an air heater and enters the bottom of the gas-liquid mixer, and is fully mixed with the emulsion to form a uniform air-emulsion mixture. The mixture enters the top 1 / 3 of the VOC removal tower, and another group of air ( The air velocity is 75m 3 / h, 0.1MPa) is heated by an air heater to 35°C and then enters the bottom of the VOC removal tower. The pure water injector at the top of the VOC removal tower sprays pure water for 1 minute after an interval of 1 minute (the flow rate of pure water is 10kg / min) to supplement Solid containment and cleaning of the tower wall, the nozzle at the top of the VOC removal tower is sprayed obliquely downw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com