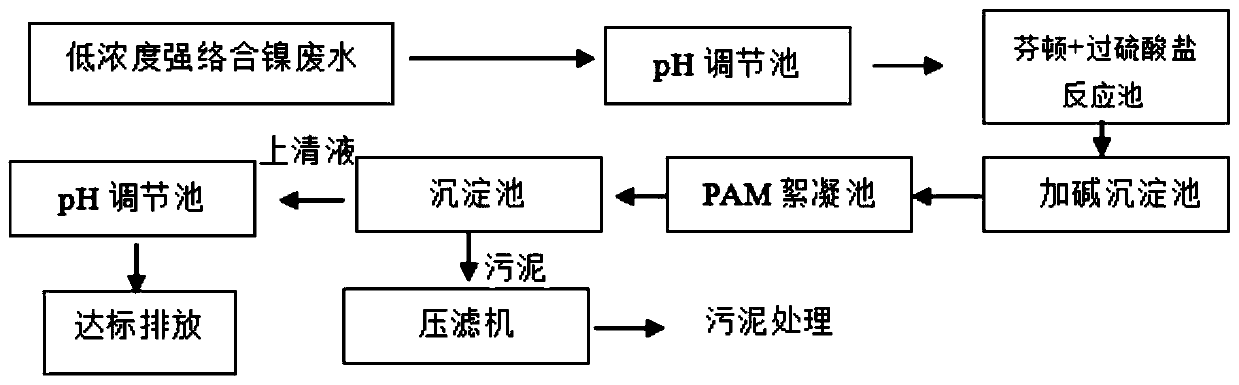

Treatment process of EDTA type high-complexation heavy metal waste water

A treatment process and heavy metal technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, sludge treatment, etc., to achieve cost saving and obvious removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The quality of nickel-containing wastewater in a semiconductor factory: suspended solids (SS) 50-80mg / L, total nickel 20-25mg / L, total phosphorus 18-25mg / L, mainly EDTA-Ni. The waste water flow rate is 10t / h, and it runs for 10 hours per day. The implementation steps of this case are as follows:

[0030] Step 1: Adjust the temperature of the waste water to 35°C through the heat exchanger, adjust the pH to 3, the dosage of H2O2 (30%) is 4.0L / h, and the dosage of FeSO4 (20%) is 9.5L / h , the dosing amount of potassium persulfate (10%) is 8.5L / h, and the reaction time for breaking the network is 2.5h;

[0031] The second step: add NaHSO3 to adjust the ORP to 200mv; adjust the pH to 11, and react for 2.5h;

[0032] The third step: add polyacrylamide (0.1%), the dosing amount is 4.0L / h, stir slowly for 2.5h for flocculation;

[0033] The fourth step: Enter the sedimentation tank and settle for 3 hours. After precipitation, the total nickel content of the supernatant is <0...

Embodiment 2

[0035] The quality of nickel-containing wastewater: suspended solids (SS) is 40-100mg / L, and the content of EDTA-Ni is 10-20mg / L. The waste water flow rate is 10t / h, and it runs for 12 hours every day. The implementation steps of this case are as follows:

[0036] Step 1: Adjust the temperature of the waste water to 35°C through the heat exchanger, adjust the pH to 3, the dosage of H2O2 (30%) is 3.0L / h, and the dosage of FeSO4 (20%) is 8.0L / h , The dosage of potassium persulfate (10%) is 7.0L / h. Broken network reaction time is 2.0h;

[0037] The second step: add NaHSO3 (10wt.%) to carry out the reduction reaction; adjust the pH to 10, and react for 2.0h;

[0038] The third step: add polyacrylamide (0.1%), the dosing amount is 6.0L / h, stir slowly for 2.0h for flocculation;

[0039] The fourth step: enter the sedimentation tank and settle for 4 hours. After precipitation, the total nickel content of the supernatant is less than 0.1mg / L, and the SS is less than 5mg / L. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com