Preparation method of long-acting stable type foam dust suppressant material

A stable, dust-suppressant technology, which is applied in the field of preparation of long-term stable foam dust-suppressant materials, can solve the problems of poor timeliness, large material consumption, and poor effect, so as to improve the suppression efficiency and action timeliness , long life, increase the effect of dust suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

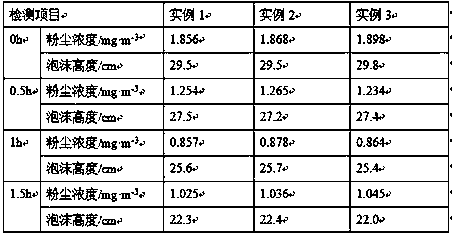

example 1

[0030] Take 500g Thuja slices and place them in a supercritical carbon dioxide extraction device, control the extraction pressure to 20MPa, the extraction temperature to 45℃, the carbon dioxide flow rate is 1.5L / min, the separation temperature is 50℃, and the extract is collected after 45min static extraction. And filter, collect the filtrate to obtain Thuja essential oil; in parts by weight, weigh 45 parts of Thuja essential oil, 10 parts by mass 85% ethanol solution and 25 parts by mass 30% sulfuric acid solution in a beaker, stir and mix and Incubate the reaction at 45℃ for 6h, let it stand and cool to room temperature, obtain the reaction solution and place it in a separatory funnel, stand for layering and collect the upper oil phase. Use saturated sodium bicarbonate solution at 25℃ for the upper oil phase After neutralizing to pH 7.0, washing with deionized water twice, separating and collecting the reaction oil phase by distillation; add corn starch to deionized water at a...

example 2

[0032] Take 500g Thuja slices and place them in a supercritical carbon dioxide extraction device, control the extraction pressure to 25MPa, extraction temperature to 47°C, and collect the extract after the carbon dioxide flow rate is 1.7L / min, the separation temperature is 52°C and static extraction for 47 minutes. And filter, collect the filtrate to obtain Thuja essential oil; in parts by weight, respectively weigh 47 parts of Thuja essential oil, 12 parts of 85% ethanol solution and 27 parts of 30% sulfuric acid solution in a beaker, stir and mix and Incubate the reaction at 47℃ for 7 hours, let it stand and cool to room temperature, obtain the reaction solution and place it in a separatory funnel, stand still to separate the layers and collect the upper oil phase. Use saturated sodium bicarbonate solution at 25℃ for the upper oil phase After neutralizing to pH 7.0, washing with deionized water twice, separating and collecting the reaction oil phase by distillation; add corn s...

example 3

[0034] Take 500g of Thuja slices and place them in a supercritical carbon dioxide extraction device, control the extraction pressure to 30MPa, the extraction temperature to 50℃, the carbon dioxide flow rate is 2.0L / min, the separation temperature is 55℃, and the extract is collected after 60min static extraction. And filter, collect the filtrate to obtain Thuja essential oil; in parts by weight, respectively weigh 50 parts Thuja essential oil, 15 parts by mass 85% ethanol solution and 30 parts by mass 30% sulfuric acid solution in a beaker, mix and mix Incubate the reaction at 50℃ for 8h, let it stand and cool to room temperature, obtain the reaction solution and place it in a separatory funnel, stand for layering and collect the upper oil phase. Use saturated sodium bicarbonate solution at 25℃ for the upper oil phase After neutralizing to pH 7.0, washing with deionized water for 3 times, separating and collecting the reaction oil phase by distillation; adding corn starch to dei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com