A kind of preparation method of molybdenum disulfide film

A molybdenum disulfide thin film technology, which is applied in the field of molybdenum disulfide thin film preparation, can solve the problems of poor film performance, many sulfur vacancies in the film, and difficulty in controlling the disorder of the film, so as to achieve a uniform number of layers, reduce the number of sulfur vacancies, and the number of layers high quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

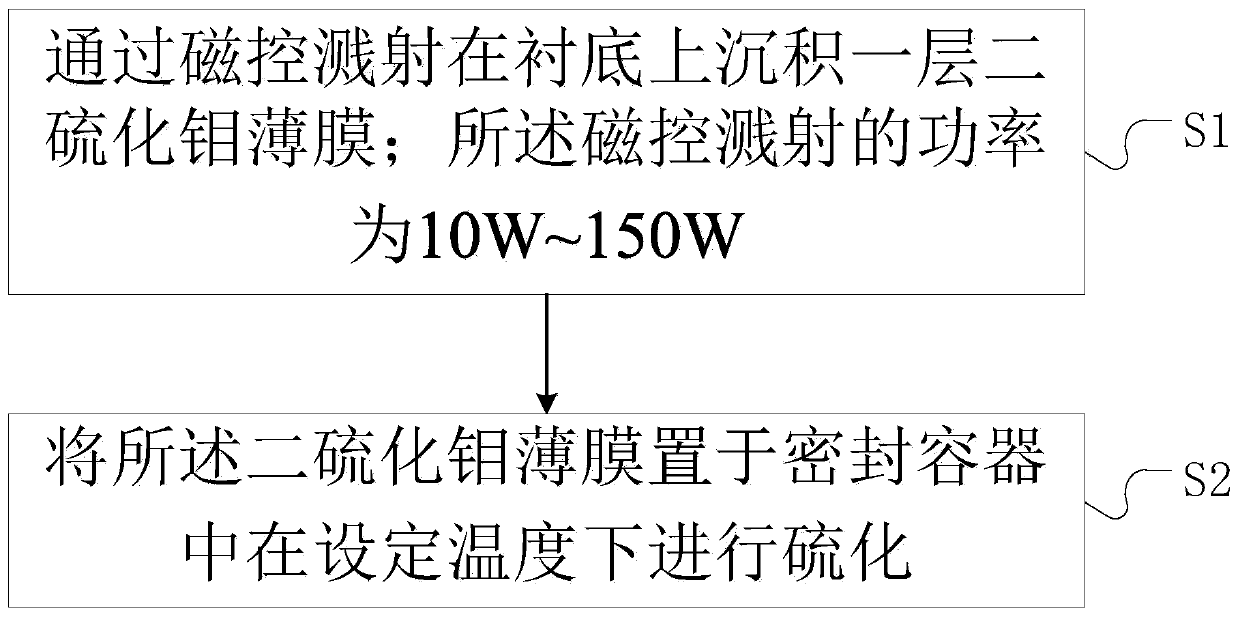

[0026] refer to figure 1 , the present embodiment discloses a method for preparing a molybdenum disulfide thin film, which comprises the following steps:

[0027] S1. Deposit a layer of molybdenum disulfide thin film on the substrate by magnetron sputtering.

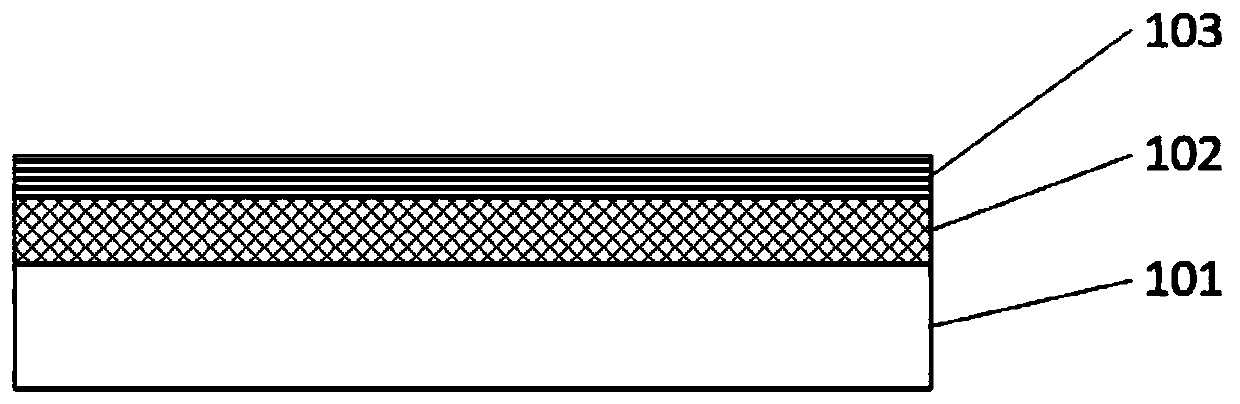

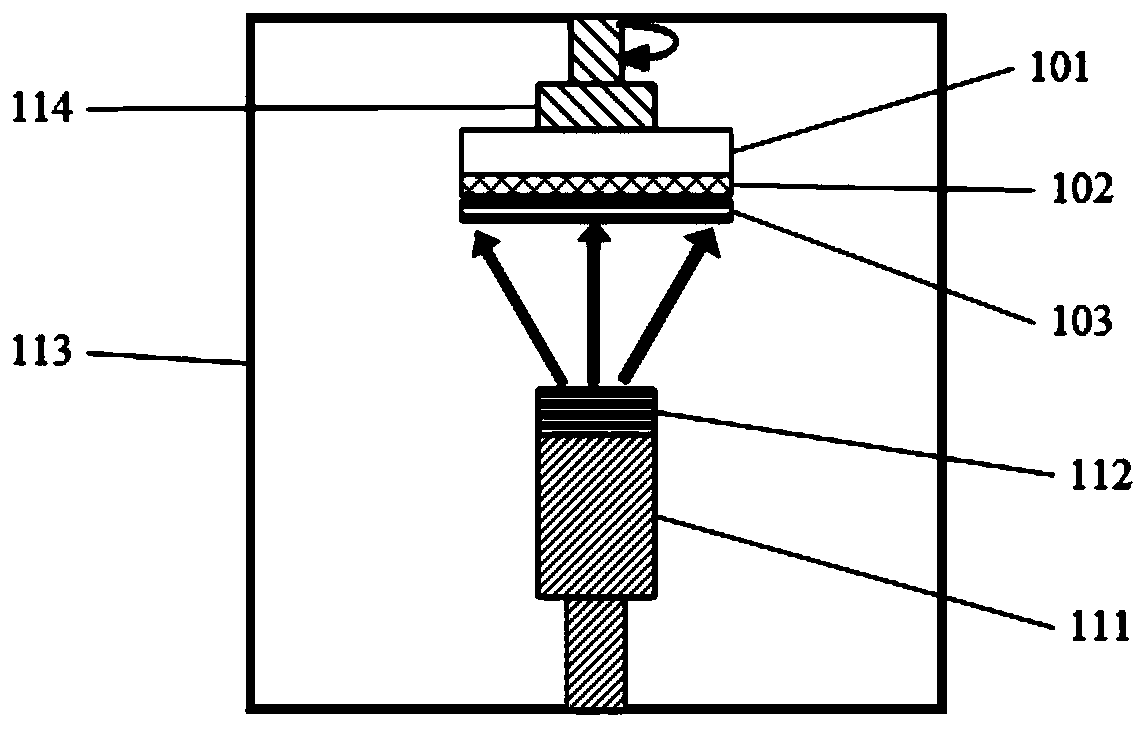

[0028] like figure 2 As shown, the cross-sectional schematic view of the product obtained after step S1, wherein the substrate 101 is a silicon wafer, a buffer layer 102 is formed on the silicon wafer, the buffer layer 102 is silicon dioxide, and the buffer layer 102 is passed through the plasma Enhanced chemical deposition method formation. like image 3 As shown, above the buffer layer 102, a radio frequency power supply 111 is used to magnetron sputter molybdenum disulfide target 112 to deposit a prefabricated molybdenum disulfide film 103. In this embodiment, the purity of the selected molybdenum disulfide target 112 is 99.99%.

[0029] In some other embodiments, the substrate may be glass provided with a buffe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com