A kind of LED encapsulation body and its manufacturing method

A technology of LED package body and installation area, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of reduced luminous flux of LED light source, blackening of substrate reflection area, etc., achieve high transparency, reduce light loss, and avoid blackening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

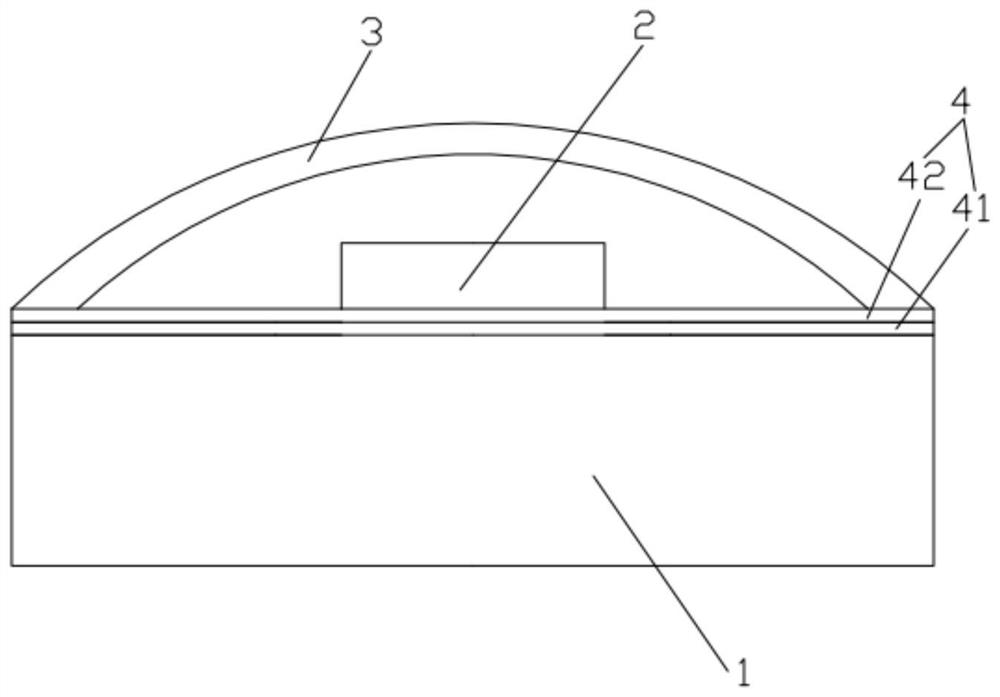

[0029] Such as figure 1 As shown, the LED package includes a substrate 1 , an ultraviolet LED chip 2 and a light-transmitting shell 3 , and the light-transmitting shell 3 covers the ultraviolet LED chip 2 . The upper surface of the substrate 1 is provided with a PET reflective film 4 , and the ultraviolet LED chip 2 is installed and fixed on the PET reflective film 4 . The PET reflective film 4 comprises a PET base material 41 and an aluminum-plated reflective layer 42 located on the upper surface of the PET base material 41. The corrosion resistance of the aluminum-plated reflective layer 42 is higher than that of the silver-plated reflective layer, and the aluminum-plated reflective layer The anti-ultraviolet performance of the reflective layer 42 is stronger than that of the silver-plated reflective layer; the gas and water vapor permeability of the PET substrate 41 is low, and it has excellent gas barrier, water oil and odor performance, and has high transparency, which ca...

Embodiment 2

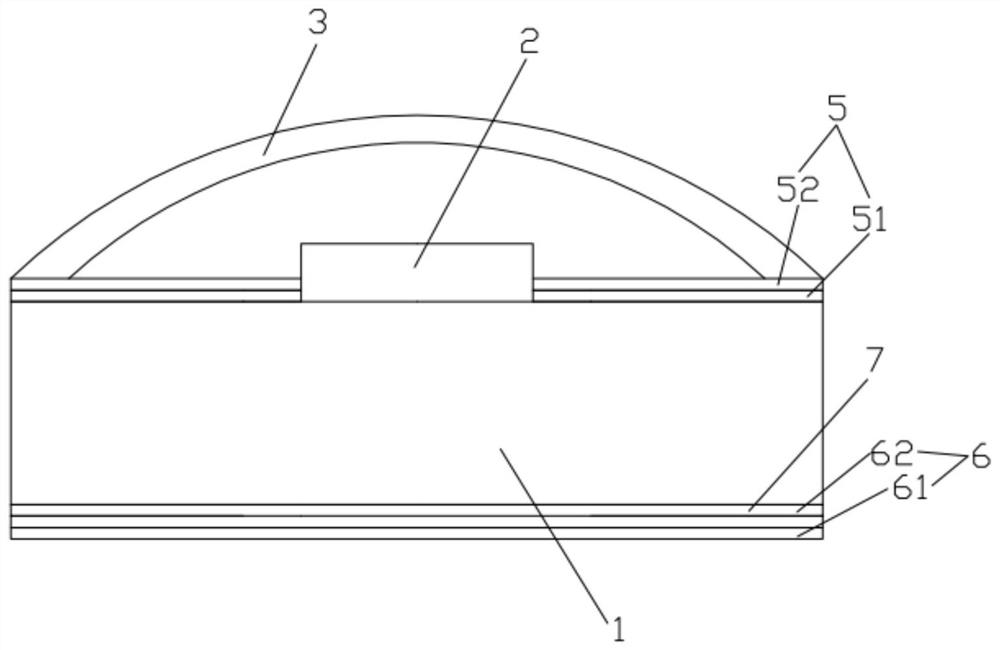

[0035] Such as figure 2 As shown, the LED package includes a substrate 1 , an ultraviolet LED chip 2 and a light-transmitting shell 3 , and the light-transmitting shell 3 covers the ultraviolet LED chip 2 . The upper surface of the substrate 1 includes an installation area and a reflective area, where the ultraviolet LED chip 2 is installed and fixed, and a first PET reflective film 5 is provided in the reflective area. The first PET reflective film 5 comprises a first PET substrate 51 and a first aluminized reflective layer 52 provided with an upper surface of the first PET substrate 51, and the corrosion resistance of the first aluminized reflective layer 52 is higher than that of the silver-plated reflective layer. The anti-corrosion performance of the first PET substrate 51 is higher, and the anti-ultraviolet performance of the first aluminum-coated reflective layer 52 is stronger than that of the silver-plated reflective layer; the gas and water vapor permeability of the...

Embodiment 3

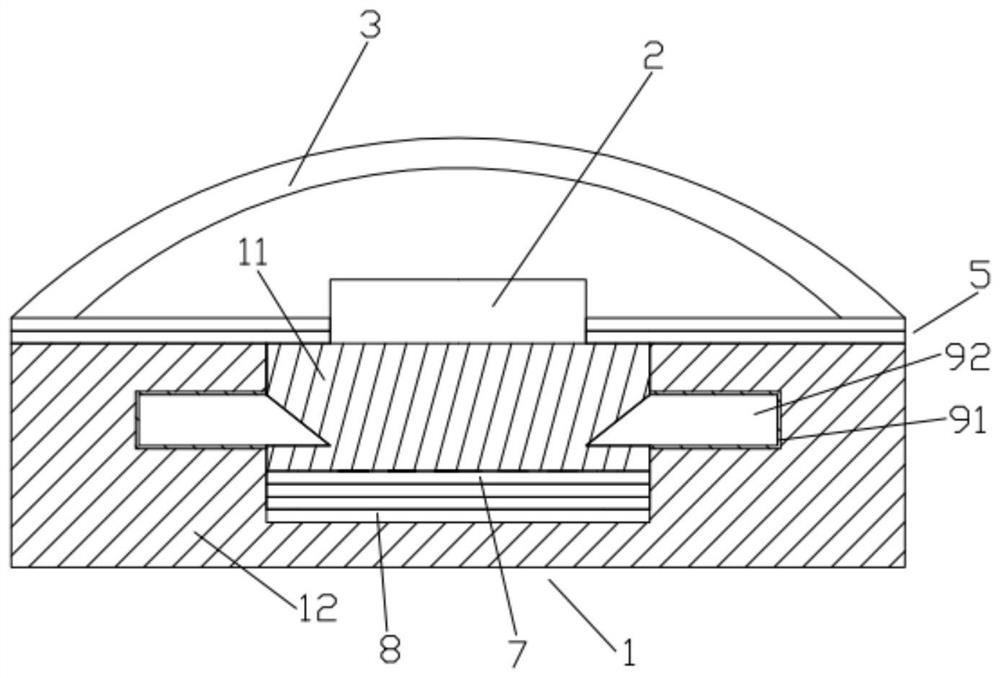

[0040] Such as image 3 and Figure 4 As shown, the LED package includes a substrate 1 , an ultraviolet LED chip 2 and a light-transmitting shell 3 , and the light-transmitting shell 3 covers the ultraviolet LED chip 2 . The difference from Embodiment 2 is that the substrate 1 includes a transparent substrate 11 and a heat dissipation substrate 12 , the heat dissipation substrate 12 is provided with a mounting groove 121 , and the transparent substrate 11 is mounted and fixed in the mounting groove 121 . Silica gel 8 or adhesive is provided between the lower surface of the second PET reflective film 6 and the bottom of the installation groove 121 , so as to install and fix the transparent substrate 11 in the installation groove 121 . The heat generated when the ultraviolet LED chip 2 is in use is conducted to the heat dissipation substrate 12 through the transparent substrate 11, thereby effectively improving the heat dissipation performance of the LED package.

[0041]As an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com