Method for fast online recovery of reversible voltage drop of fuel cell stack

A fuel cell stack and voltage drop technology, applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of reducing the service life of the stack, affecting the performance and normal operation of the stack, and improving the performance and reducing the recovery oxidant. Supply, Guaranteed Integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

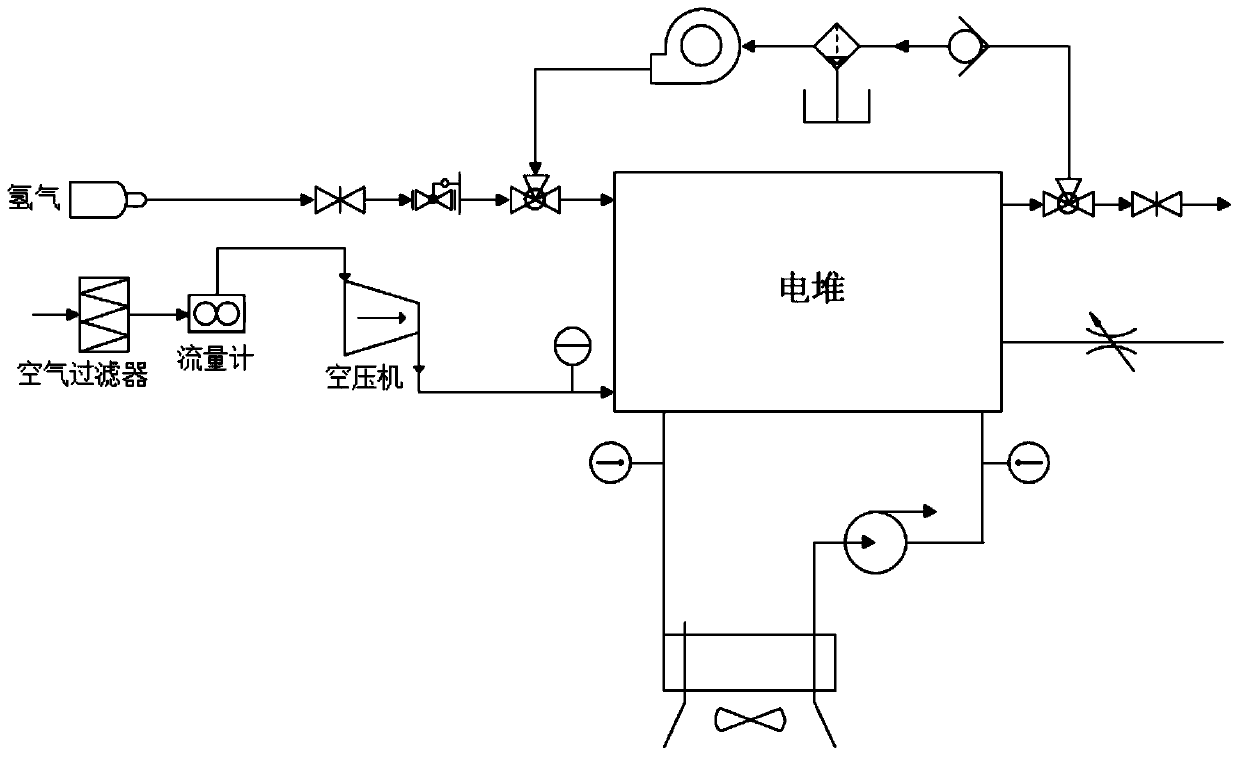

[0024] Assembly circuit diagram: as figure 1 As shown, connect the auxiliary parts in normal operation and the stack that meet the standard according to the assembly drawing, and fill the flow channel with 20kPa of N2 to detect whether there is air leakage in the connected line. If there is air leakage, it is necessary to detect the leakage point and fix it Solved, if there is no air leakage, proceed to the next step.

[0025] Strategy loading: Turn on the constant temperature water circulation system of the system to keep the stack at a constant temperature of 60°C. Before filling the stack with hydrogen, it is necessary to use nitrogen to purge the hydrogen flow channel to remove impurities in the hydrogen flow channel. Switch after a certain period of time. Hydrogen supply The fuel cell generates electricity normally, and increases the current at a certain speed. Before loading, the gas supply under the next load of the stack needs to be given to ensure sufficient fuel supp...

Embodiment 2

[0030] Assembly circuit diagram: Connect the auxiliary parts in normal operation and the standard stack according to the assembly diagram, and fill the flow channel with 20kPa of N2 to detect whether there is air leakage in the connected line. If there is air leakage, it is necessary to detect the air leakage point and Solve it, and proceed to the next step if there is no air leakage.

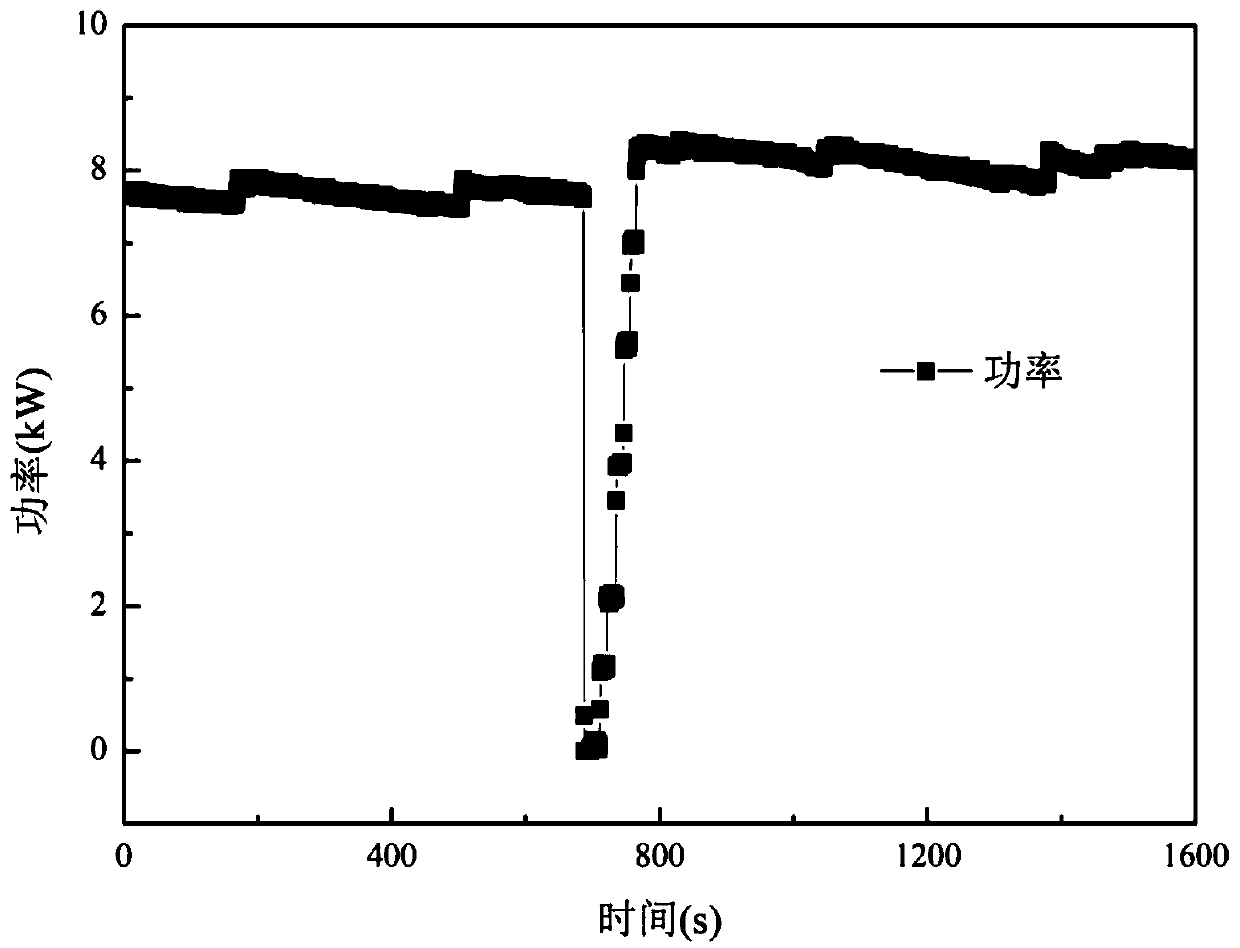

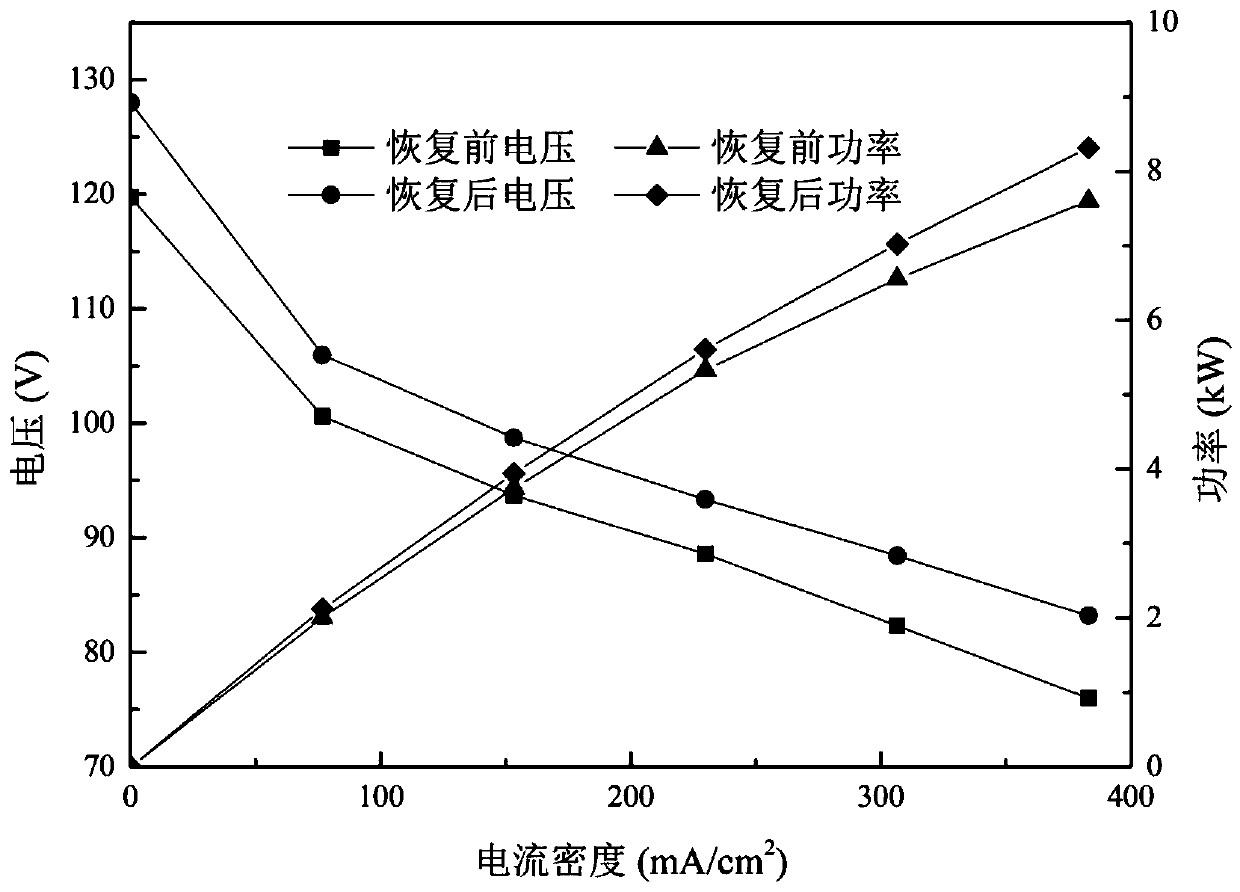

[0031] Strategy loading: Turn on the constant temperature water circulation system of the system to keep the stack at a constant temperature of 60°C. Before filling the stack with hydrogen, it is necessary to use nitrogen to purge the hydrogen flow channel to remove impurities in the hydrogen flow channel. Switch after a certain period of time. Hydrogen supply The fuel cell generates electricity normally, and increases the current at a certain speed. Before loading, the gas supply under the next load of the stack needs to be given to ensure sufficient fuel supply. When the load reaches 100A, sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com