Drug continuous granulation method

A technology of medicine and production method, which is applied in the field of continuous granulation of medicine, can solve the problems of difficult enlargement, low efficiency, and high energy consumption of spray drying granulation, and achieve the goal of enhancing cohesive force, improving production efficiency, and improving product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

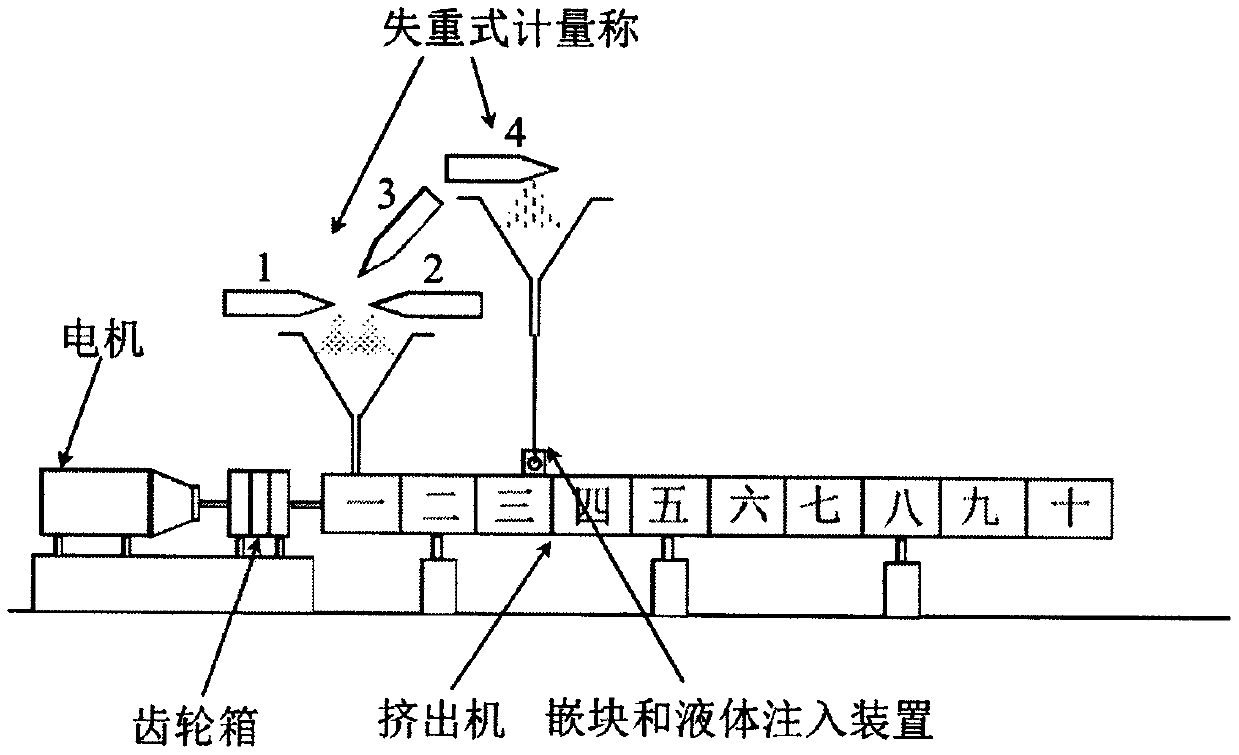

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation examples, but the embodiments of the present invention are not limited thereto.

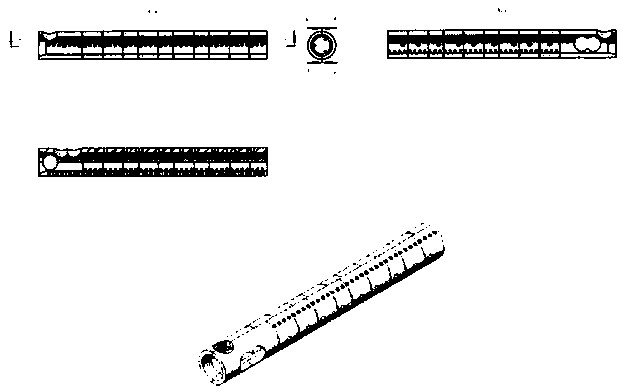

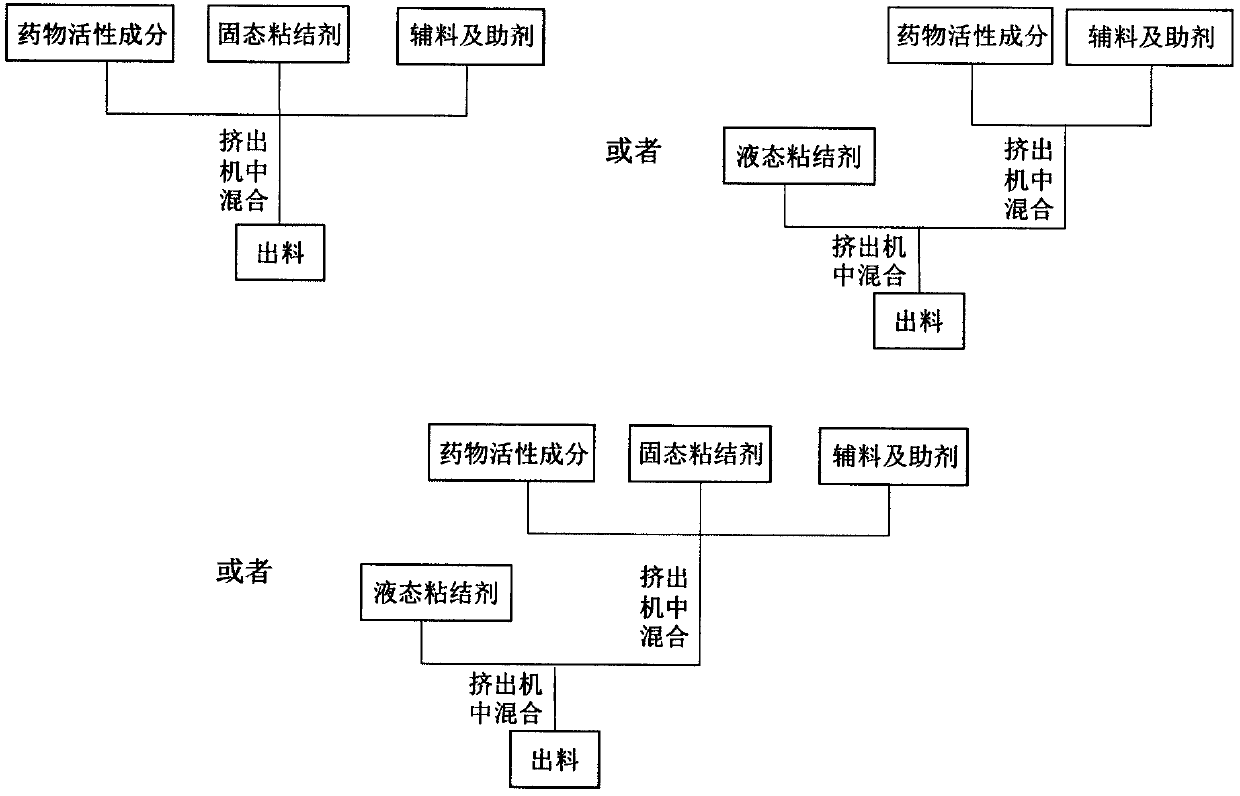

[0028] see figure 1 and figure 2 As shown, the continuous granulation production process of the drug is as follows:

[0029] Step 1: Start the reciprocating single-screw extruder, set the speed of the extruder to 100 rpm, and set the barrel temperature in each zone of the extruder to 40 degrees Celsius (the first zone is not heated);

[0030] Step 2: according to the pharmaceutical formula, theophylline of 30% of the active substance of the drug, the polyvinylpyrrolidone of 2.5% of the solid binder, the lactose (filler) of the auxiliary material 58% and the magnesium stearate of the lubricant of 0.5% (prepared with lactose Pre-mixed together) 1, 2 and 3 are quantitatively and continuously added to the barrel of the first zone of the reciprocating single-screw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com