A nanoscale metal fluoride catalyst with confined structure and its preparation method and application

A nano-scale, fluoride technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, dehydrohalogenation preparation, etc. See reports and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

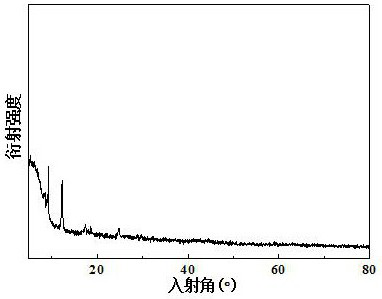

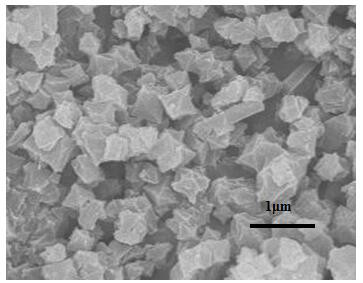

[0029] 3.33g terephthalic acid (C 8 h 6 o 4 ) and 8g chromium nitrate nonahydrate (Cr(NO 3 ) 3 9H 2 O) be dissolved in 160mL deionized water, then add 0.92mL hydrofluoric acid (concentration 40%), magnetically stir for 10min to obtain the solution, place the above solution in a stainless steel autoclave lined with 250mL polytetrafluoroethylene, and The crystallization reaction was carried out in a drying oven at 220° C. for 8 hours. After the reaction, the stainless steel autoclave was taken out, and after it was naturally cooled to room temperature, the reaction product mixture in the stainless steel autoclave was removed. The reaction product mixture was centrifuged to obtain crude MIL-101. Then the crude MIL-101 was washed with 500mL deionized water at 70°C for 6h, and then centrifuged. The obtained sample was washed with 500mL DMF at 70°C for 12h, and then centrifuged. The obtained sample was washed with 300mL absolute ethanol at 70°C. Wash for 6h and twice, then cen...

Embodiment 2

[0035] 3.33g terephthalic acid (C 8 h 6 o 4 ) and 8g chromium nitrate nonahydrate (Cr(NO 3 ) 3 9H 2 O) be dissolved in 160mL deionized water, then add 0.92mL hydrofluoric acid (concentration 40%), magnetically stir for 10min to obtain the solution, place the above solution in a stainless steel autoclave lined with 250mL polytetrafluoroethylene, and The crystallization reaction was carried out at 220° C. in a drying oven for 8 hours. After the reaction, the stainless steel autoclave was taken out, and after it was naturally cooled to room temperature, the reaction product mixture in the stainless steel autoclave was removed. The reaction product mixture was centrifuged to obtain crude MIL-101. Then the crude MIL-101 was washed with 500mL deionized water at 70°C for 6h, and then centrifuged. The obtained sample was washed with 500mL DMF at 70°C for 12h, and then centrifuged. Wash with ethanol for 6 h and twice, then centrifuge the obtained sample at 70°C with 500 mL NH 4 ...

Embodiment 3

[0041] 3.02g triethyl benzene tricarboxylate (C 15 h 18 o 6 ) and 6.67g aluminum nitrate nonahydrate (Al(NO 3 ) 3 9H 2 O) Dissolve in 50mL deionized water, then add 10mL HNO 3 Aqueous solution (4mol / L), magnetically stirred for 10min to obtain the solution, the above solution was placed in a 250mL polytetrafluoroethylene-lined stainless steel autoclave, and crystallized in a blast drying oven at 210°C for 72h. After the reaction, The stainless steel autoclave was taken out, and after it was naturally cooled to room temperature, the reaction product mixture in the stainless steel autoclave was removed. The reaction product mixture was centrifuged, and the resulting solid was washed with deionized water and dried overnight at 80°C to obtain a yellow powder, which was the precursor MIL-110.

[0042] Place the resulting precursor MIL-101 in N 2 Calcined at 400°C for 3h under atmosphere, N 2 The flow rate is 30mL / min, and the N 2 Switch to mixed gas (N 2 / O 2 =1 / 99, volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com