A kind of clarification method of alkali-free glass melting under reduced pressure

An alkali-free glass and melting technology, applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of affecting glass quality and many bubbles, and achieve a small number of residual bubbles, small bubble diameter, and homogeneity. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

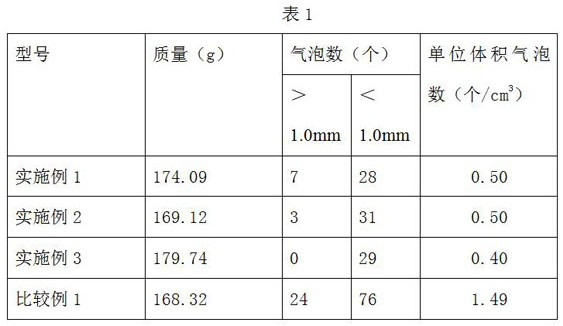

Embodiment 1

[0011] In terms of mass percentage, the following alkali-free glass batch materials are selected: 59% SiO 2 , 15.2% Al 2 o 3 , 0.6% ZrO 2 , 7% B 2 o 3 , 4% MgO, 3% CaO, 6% SrO, and 1.2% MoO 3 , 2% SrF 2 , 2% CaCl 2 Carry out batching according to these each component, first vacuumize the melting furnace (decompression treatment), until the pressure in the furnace is 0.8 standard atmospheric pressure, the melting of glass is carried out according to the following melting system: from room temperature to 1100 ℃, it takes 2 hours; it takes 3 hours to rise from 1100 ℃ to 1640 ℃, and it takes 2 hours to keep warm and clarify; after the clarification, air is introduced into the melting furnace to adjust the air pressure balance inside and outside the furnace. Casting method, followed by annealing, cutting and polishing processes to obtain the glass substrate.

Embodiment 2

[0013] In terms of mass percentage, the following alkali-free glass batch materials are selected: 59% SiO 2 , 15.2% Al 2 o 3 , 0.6% ZrO 2 , 7% B 2 o 3 , 4% MgO, 3% CaO, 6% SrO, and 1.2% MoO 3 , 2% SrF 2 , 2% CaCl 2 Carry out batching according to these each component, first vacuumize the melting furnace (decompression treatment), until the pressure in the furnace is 0.7 standard atmospheric pressure, the melting of glass is carried out according to the following melting system: from room temperature to 1100 ℃, it takes 2 hours; it takes 3 hours to rise from 1100 ℃ to 1640 ℃, and it takes 2 hours to keep warm and clarify; after the clarification, air is introduced into the melting furnace to adjust the air pressure balance inside and outside the furnace. Casting method, followed by annealing, cutting and polishing processes to obtain the glass substrate.

Embodiment 3

[0015] In terms of mass percentage, the following alkali-free glass batch materials are selected: 59% SiO 2 , 15.2% Al 2 o 3 , 0.6% ZrO 2 , 7% B 2 o 3 , 4% MgO, 3% CaO, 6% SrO, and 1.2% MoO 3 , 2% SrF 2 , 2% CaCl 2 Carry out ingredients according to these components, first vacuumize the melting furnace (decompression treatment), until the pressure in the furnace is 0.5 standard atmospheric pressure, the melting of glass is carried out according to the following melting system: from room temperature to 1100 ℃, it takes 2 hours; it takes 3 hours to rise from 1100 ℃ to 1640 ℃, and it takes 2 hours to keep warm and clarify; after the clarification, air is introduced into the melting furnace to adjust the air pressure balance inside and outside the furnace. Casting method, followed by annealing, cutting and polishing processes to obtain the glass substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com