A spherical resin-based brush composite material and its preparation method

A composite material and resin-based technology, applied in the field of spherical resin-based brush composite materials and their preparation, to achieve the effects of improving self-fluidity, eliminating edges and corners, improving lubrication and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

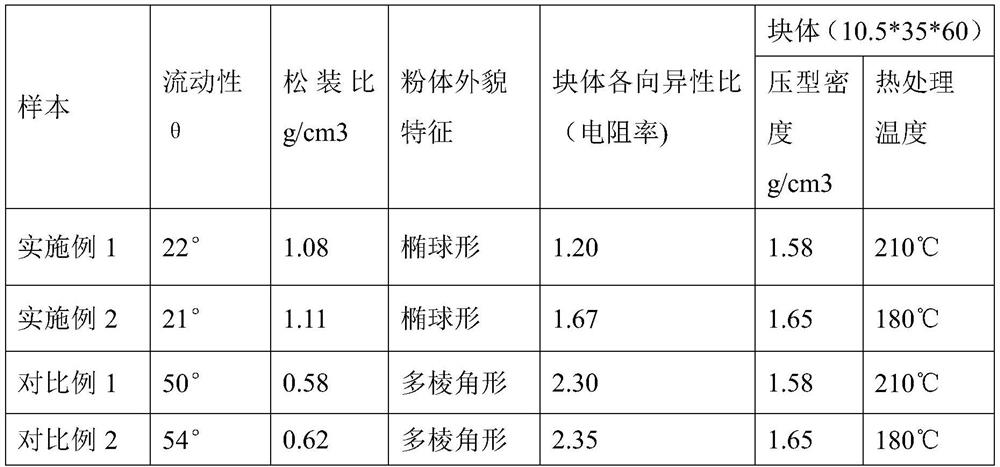

Examples

Embodiment 1

[0033] Spherical resin-based brush composite material, comprising the following components in mass percentages:

[0034] Microcrystalline graphite powder 23%

[0035] 10% spherical flake graphite powder

[0036] Spheroidized artificial graphite powder 42%

[0037] Titanate coupling agent 1%

[0038] Epoxy 22%

[0039] Tungsten disulfide 1.75%

[0040] Ceria 0.25%.

[0041] The preparation method of spherical resin-based electric brush composite material comprises the following steps:

[0042]Add microcrystalline graphite powder, spheroidized flake graphite powder and spheroidized artificial graphite powder, tungsten disulfide, and cerium dioxide into the mixing pot, close the lid and mix for 20 minutes to obtain material a; open the lid, and add titanate to material a For coupling agent and chelating agent, mix at 50°C for 30 minutes with the cover closed to obtain material b; open the cover, add epoxy resin binder to material b, close the cover and mix for 90 minutes, c...

Embodiment 2

[0044] Spherical resin-based brush composite material, comprising the following components in mass percentages:

[0045] Microcrystalline graphite powder 30%

[0046] Spheroidized artificial graphite powder 43%

[0047] Silane coupling agent 0.5%

[0048] Thermosetting phenolic resin 25%

[0049] Tungsten disulfide 1.2%

[0050] Ceria 0.3%

[0051] The preparation method of spherical resin-based electric brush composite material comprises the following steps:

[0052] Add microcrystalline graphite powder, spheroidized flake graphite powder and spheroidized artificial graphite powder, tungsten disulfide, and cerium dioxide into the mixing pot, close the lid and mix for 20 minutes to obtain material a; open the lid, and add titanate to material a For coupling agent and chelating agent, close the cover and mix for 30 minutes at 50°C to obtain material b; open the cover, add thermosetting phenolic resin binder to material b, close the cover and mix for 90 minutes, continue mi...

Embodiment 3

[0054] Spherical resin-based brush composite material, comprising the following components in mass percentages:

[0055] Microcrystalline graphite powder 15%

[0056] Spherical flake graphite powder 63%

[0057] Titanate coupling agent 0.215%

[0058] Thermoplastic phenolic resin 20%

[0059] Tungsten disulfide 1.5%

[0060] Ceria 0.285%.

[0061] The preparation method of spherical resin-based electric brush composite material comprises the following steps:

[0062] Add microcrystalline graphite powder, spheroidized flake graphite powder and spheroidized artificial graphite powder, tungsten disulfide, and cerium dioxide into the mixing pot, close the lid and mix for 20 minutes to obtain material a; open the lid, and add titanate to material a For coupling agent and chelating agent, close the cover and mix for 30 minutes at 50°C to obtain material b; open the cover, add thermoplastic phenolic resin binder to material b, close the cover and mix for 90 minutes, continue mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com