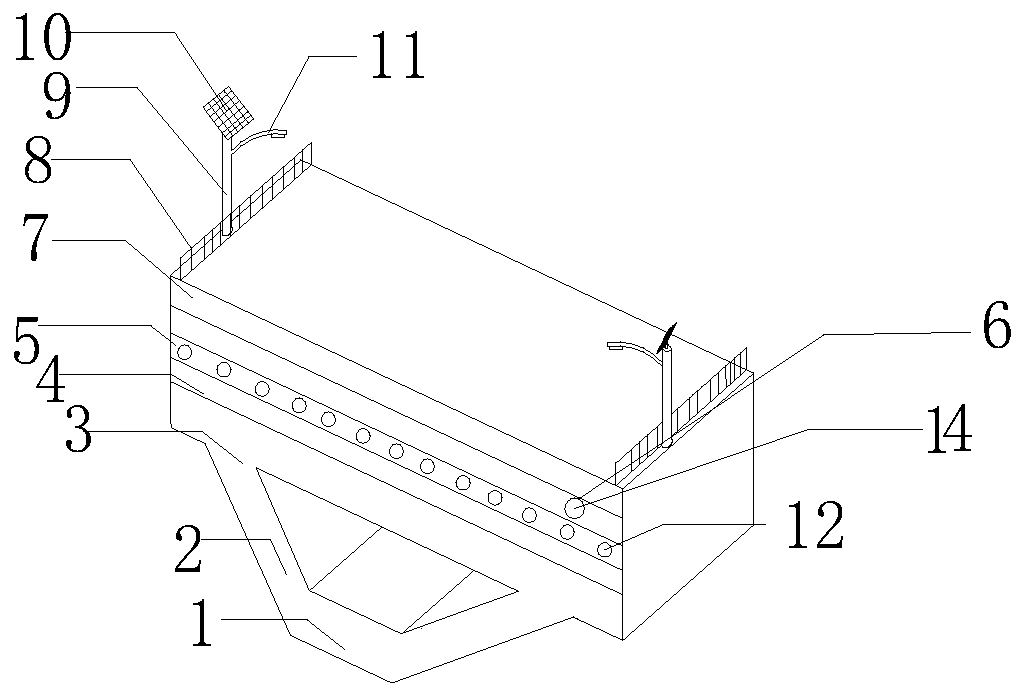

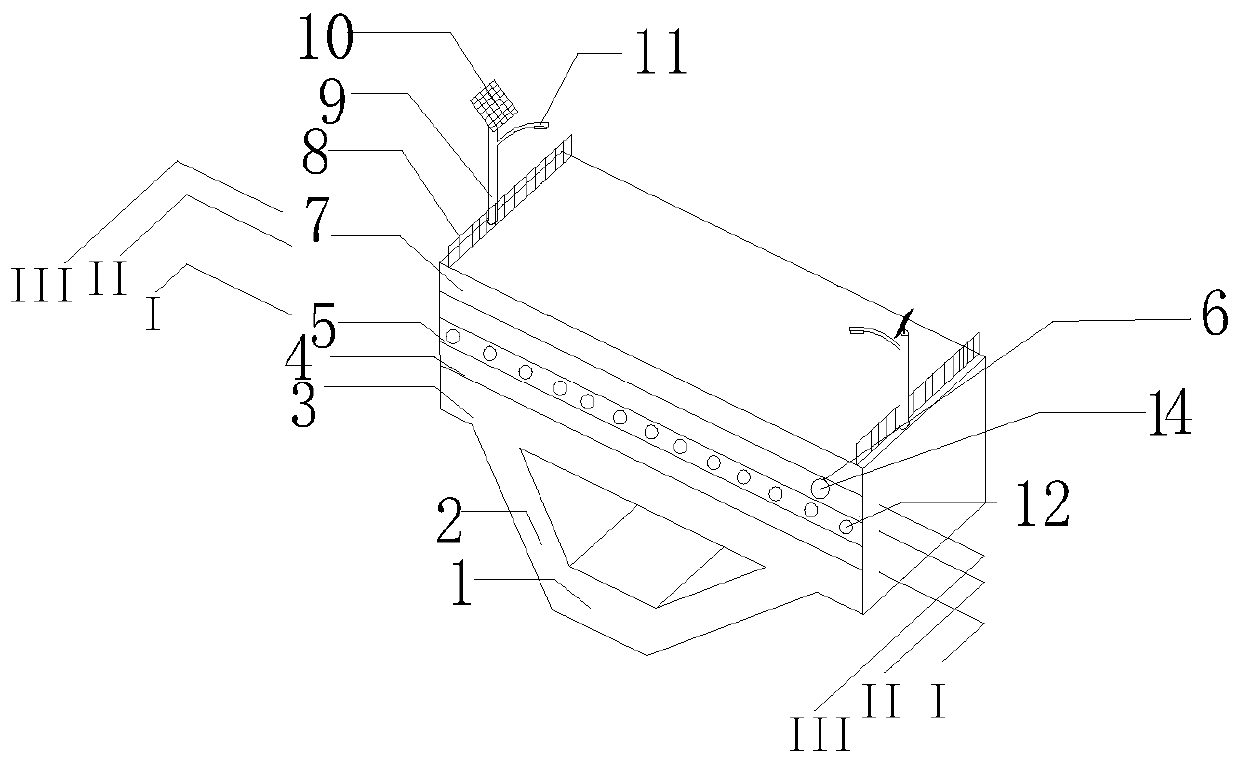

Colorful UHPC bridge system with functions of melting ice and snow and degrading tail gas

A technology for degrading exhaust gas and bridges, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as high cost, poor stability, and complicated procedures, and achieve the effect of alleviating driving fatigue and reducing the difficulty of transportation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

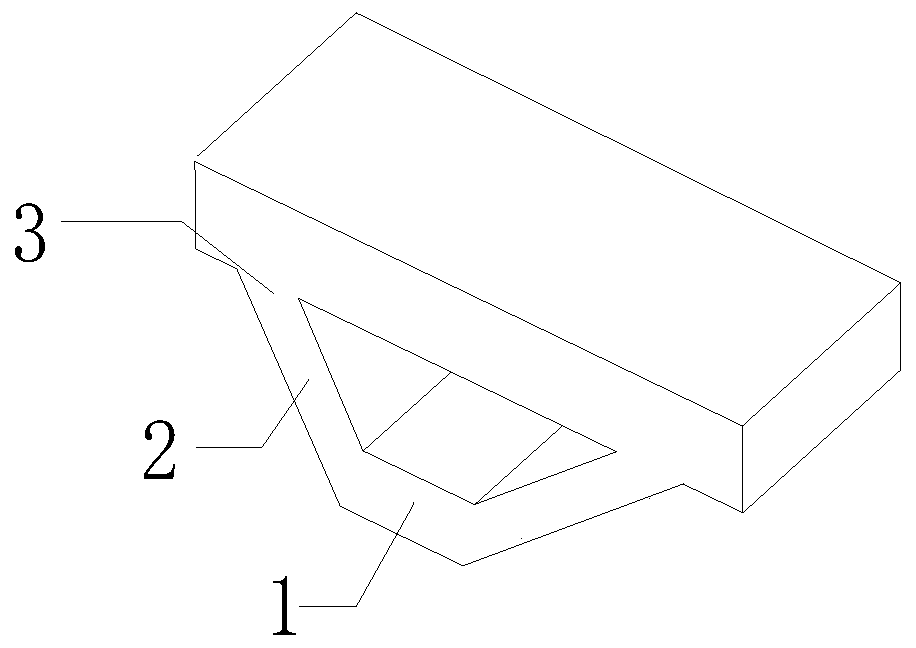

Method used

Image

Examples

Embodiment -1

[0048] [Example-1] Cement is produced by Yangzhou Luyang Cement Development Co., Ltd., P.O52.5 grade ordinary Portland cement; silica fume is produced by Shanghai Shengkuo Building Materials Co., Ltd., SiO 2 The content is more than 95%; ultrafine slag is produced by Rongxingda Mineral Powder Factory in Licheng District, Jinan, with a specific surface area of 1200m 2 / kg; Regenerated colored glass particles are produced by Changzhou Baogu Glass Products Co., Ltd., with a particle size of no more than 2.5mm; nano-zirconia is produced by Nanjing Haitai Nano Materials Co., Ltd., HTZr-01 type, with an average particle size of 20nm; nano-titanium dioxide It is produced by Nanjing Haitai Nano Materials Co., Ltd., HTTi01-N type, with an average particle size of 20nm, and the copper-coated microwire steel fiber is produced by Jiangsu Subote New Material Co., Ltd., with a fiber length of 13mm; polycarboxylate superplasticizer, ether The defoamer was produced by Jiangsu Subote New Mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com