Method for separating vanillin and isovanillin by three-zone asynchronous switching simulated moving bed

A technology for simulating moving bed and isovanillin, which is applied in the field of separation of vanillin and isovanillin in a three-zone asynchronously switched simulated moving bed, can solve the problems of low efficiency and achieve low solvent consumption, high yield and stable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] a. Operating conditions

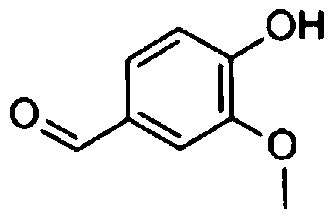

[0032] Mobile phase: ethanol: water solution with a volume ratio of 35:65;

[0033] Injection concentration: the injection concentration of vanillin and isovanillin is 0.5g / L;

[0034] Eluent flow rate: U d= 2mL / min;

[0035] Extraction flow rate: U e =0.962mL / min;

[0036] Injection liquid flow rate: U f =0.471mL / min;

[0037] Raffinate flow rate: U r =1.509mL / min;

[0038] Switching time: T s = 18.0 min.

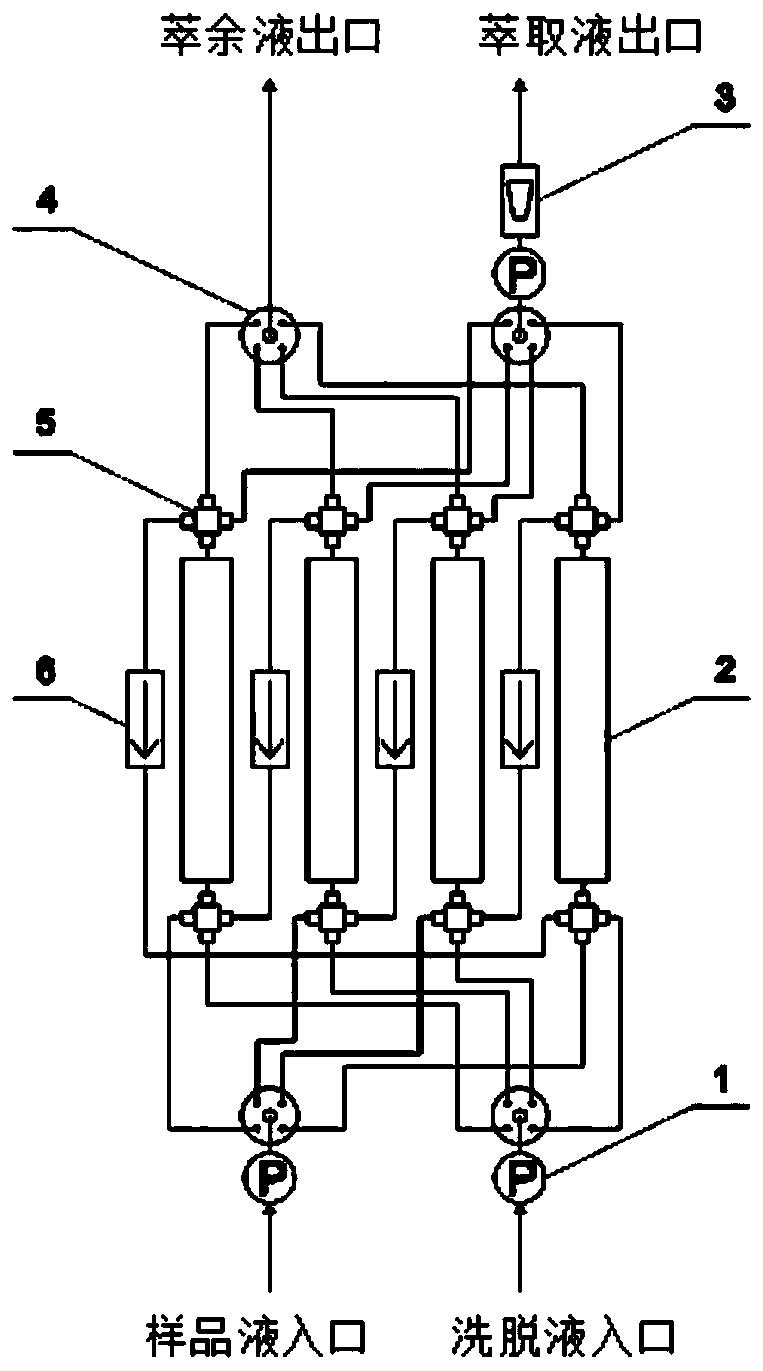

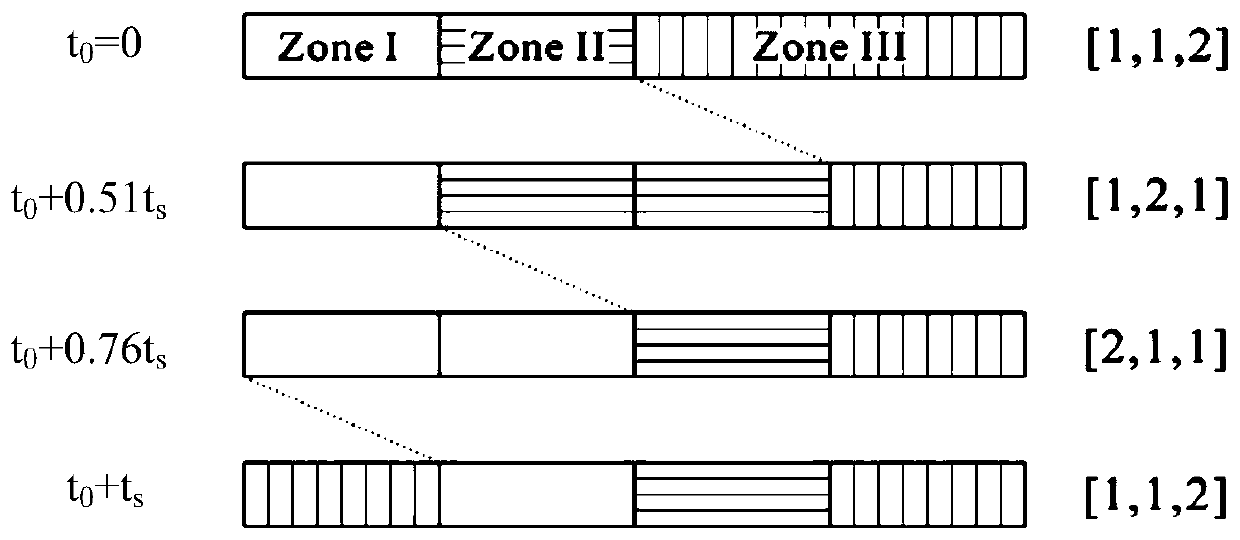

[0039] b. Separation step

[0040] Fully dissolve isovanillin and vanillin in the prepared mobile phase with a concentration of 0.5g / L. The sample solution and eluent are sequentially injected into the asynchronously switched simulated moving bed chromatography system from the injection port and the eluent inlet. Asynchronously switch the controller of the simulated moving bed chromatography system. After 9.28 minutes, the injection port advances one chromatographic column along the direction of the mobile phase. After 13.7 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com