A kind of anti-cracking waterproofing agent for concrete and preparation method thereof

An anti-crack waterproofing agent and concrete technology, applied in the field of building admixtures, can solve the problems of difficult to meet construction requirements, high environmental requirements, difficult to mix evenly, achieve good mass retention rate and volume retention rate, and improve material accumulation. effect, effect of improving compactness and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

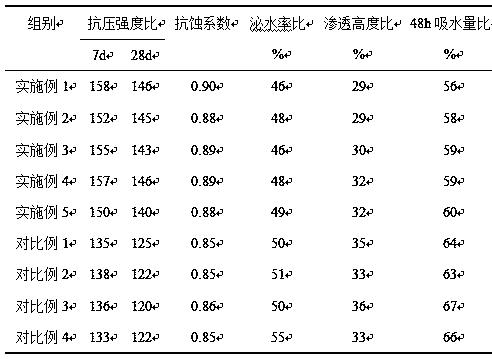

Examples

Embodiment 1

[0027] A concrete anti-crack waterproofing agent, which is prepared from the following raw materials in parts by weight: 100 parts of allophane powder, 40 parts of modified wollastonite powder, 14 parts of phenolic resin hollow microspheres, 15 parts of tricalcium phosphate, hexametaphosphoric acid 7 parts of sodium, 14 parts of 2-amino-2-methyl-propanol, 4 parts of sodium thiocyanate, 10 parts of diethanol monoisopropanolamine, and 13 parts of pentaerythritol.

[0028] Described, modified wollastonite powder is made by following method:

[0029] 1) Add ethylene-vinyl acetate copolymer emulsion, α-sulfo fatty acid methyl ester and deionized water into the reactor, stir and react at 25°C for 2 hours to obtain solution A;

[0030] 2) Put solution A, wollastonite powder, calcium chloride, and diethylene glycol monobutyl ether into the reactor, react at 50°C for 3 hours, cool to room temperature, filter, dry, and pass through a 100-mesh sieve after crushing. Active wollastonite p...

Embodiment 2

[0041] A concrete anti-crack waterproofing agent, which is prepared from the following raw materials in parts by weight: 100 parts of allophane powder, 30 parts of modified wollastonite powder, 18 parts of phenolic resin hollow microspheres, 20 parts of tricalcium phosphate, hexametaphosphoric acid 6 parts of sodium, 10 parts of 2-amino-2-methyl-propanol, 3 parts of sodium thiocyanate, 12 parts of diethanol monoisopropanolamine, and 15 parts of pentaerythritol.

[0042] Described, modified wollastonite powder is made by following method:

[0043] 1) Add ethylene-vinyl acetate copolymer emulsion, α-sulfo fatty acid methyl ester and deionized water into the reactor, stir and react at 20°C for 3 hours to obtain solution A;

[0044] 2) Put solution A, wollastonite powder, calcium chloride, and diethylene glycol monobutyl ether into the reactor, react at 50°C for 2 hours, cool to room temperature, filter, dry, and pass through a 100-mesh sieve after crushing. Active wollastonite p...

Embodiment 3

[0055] A concrete anti-crack waterproofing agent, which is prepared from the following raw materials in parts by weight: 100 parts of allophane powder, 35 parts of modified wollastonite powder, 16 parts of phenolic resin hollow microspheres, 18 parts of tricalcium phosphate, hexametaphosphoric acid 7 parts of sodium, 12 parts of 2-amino-2-methyl-propanol, 4 parts of sodium thiocyanate, 11 parts of diethanol monoisopropanolamine, and 14 parts of pentaerythritol.

[0056] Described, modified wollastonite powder is made by following method:

[0057] 1) Add ethylene-vinyl acetate copolymer emulsion, α-sulfo fatty acid methyl ester and deionized water into the reactor, stir and react at 23°C for 2.5 hours to obtain solution A;

[0058] 2) Put solution A, wollastonite powder, calcium chloride, and diethylene glycol monobutyl ether into the reactor, react at 50°C for 2.5 hours, cool to room temperature, filter, dry, and pass through a 100-mesh sieve after crushing to obtain Modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com