Solid luminescent carbon nanodot, preparing method and application

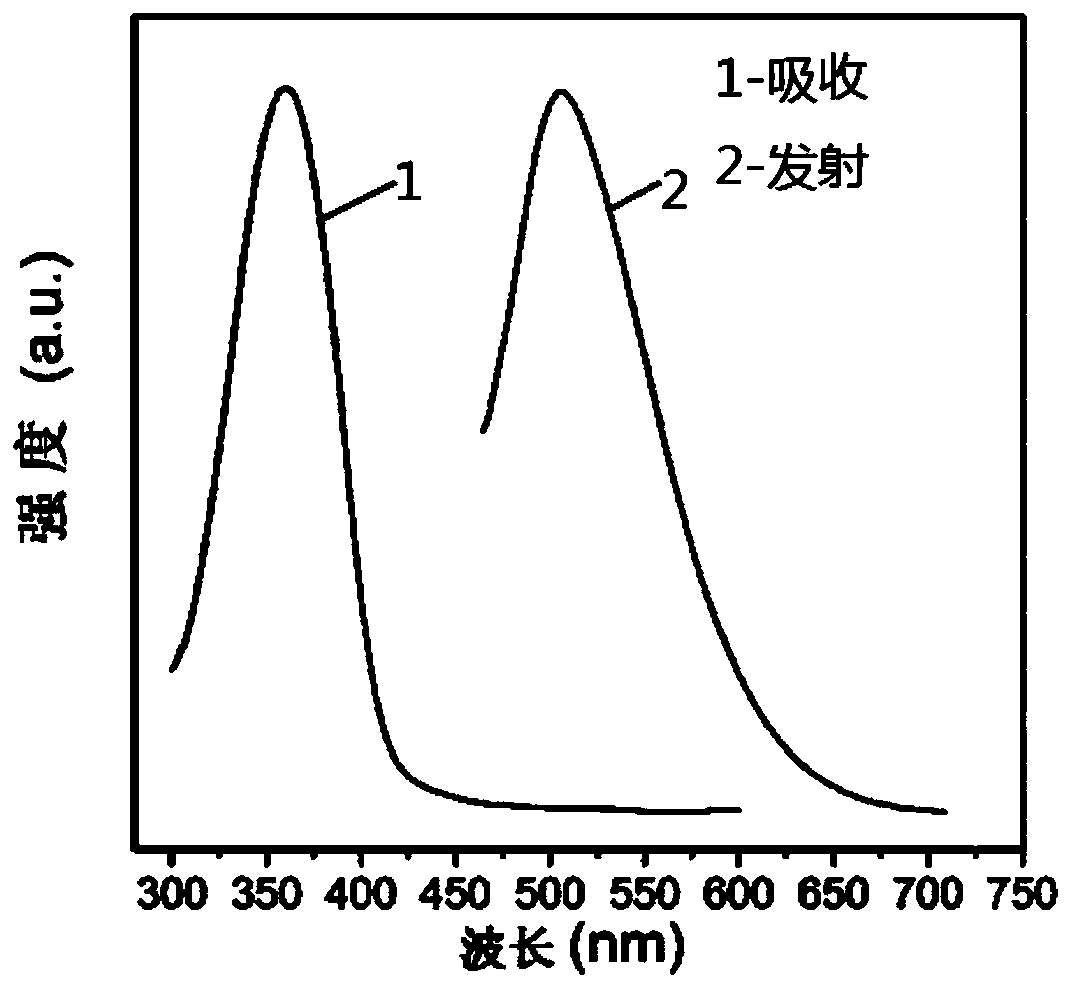

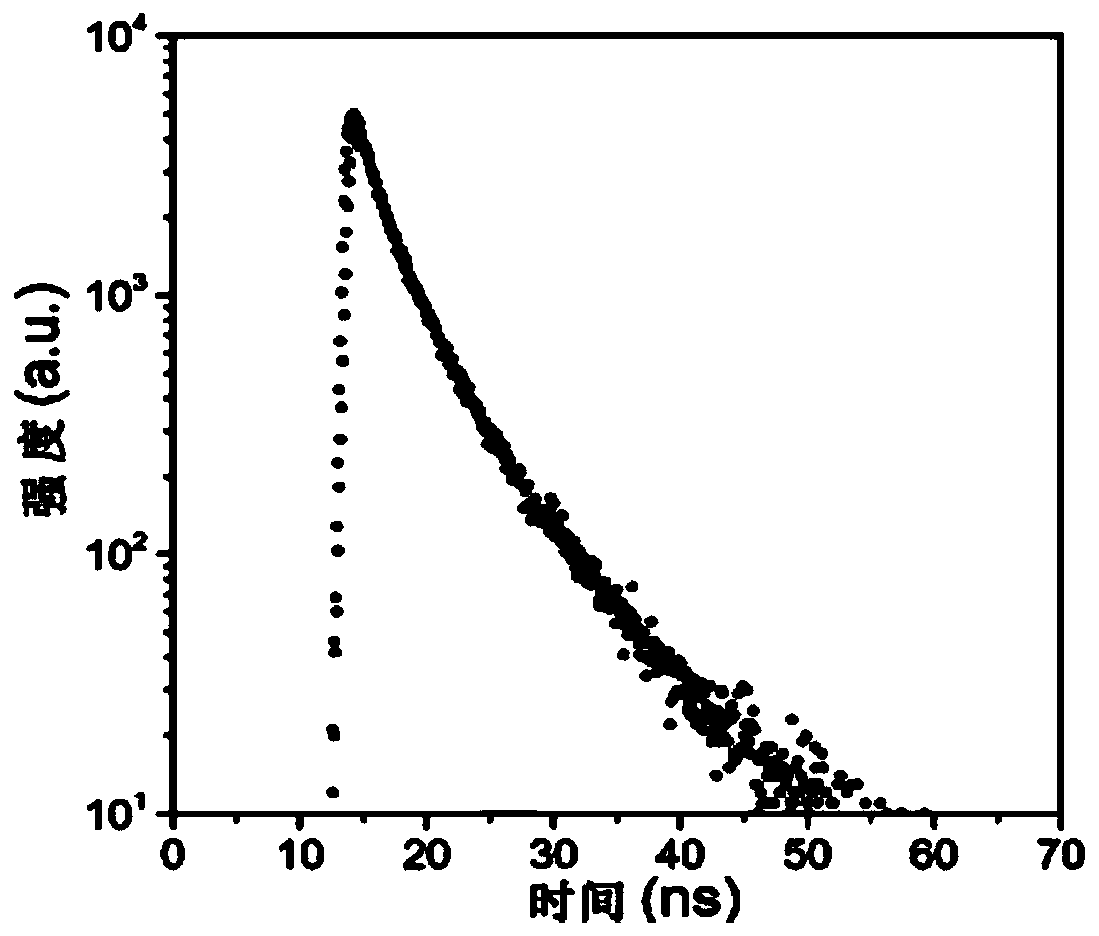

A carbon nanodot, solid-state luminescence technology, applied in the field of carbon nanodots, can solve the problems of harsh reaction conditions, need of catalysts, and high cost, and achieve the effect of short fluorescence lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

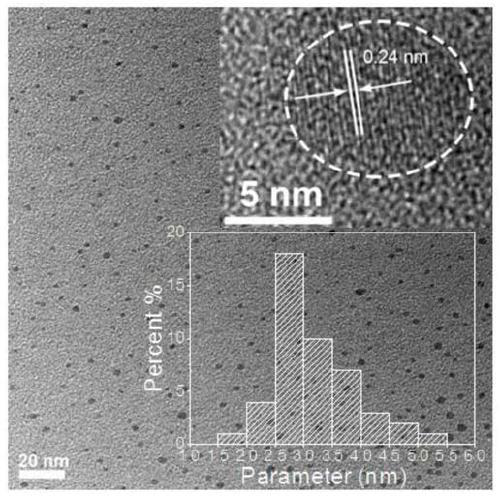

[0045] A solid-state luminescent carbon nano-dot is prepared by a solvothermal method using citric acid and a polyamine-based polymer as raw materials.

[0046] The preparation method of the above-mentioned solid-state luminescent carbon nano-dots comprises the following steps:

[0047]S1. Dissolve 3g of citric acid and 6ml of branched polyethyleneimine (50wt.% aqueous solution) with a mass average molecular weight of 2000 in 20ml of deionized water, stir evenly, then place in a closed reaction kettle, and react at 160°C for 6h ;

[0048] S2. Centrifuge the reacted solution in S1 for 3 times in a centrifuge at a speed of 8000r / min, remove insoluble polymers, and obtain a supernatant after centrifugation; transfer the supernatant obtained by centrifugation to the molecular weight cut-off Dialyze with deionized water for 5 days in a 3500 dialysis bag to obtain a dialysate, place the retained solution in the dialysis bag in a lyophilizer, lyophilize, and grind to obtain solid-st...

Embodiment 2

[0050] A solid-state luminescent carbon nano-dot is prepared by a solvothermal method using citric acid and a polyamine-based polymer as raw materials.

[0051] The preparation method of the above-mentioned solid-state luminescent carbon nano-dots comprises the following steps:

[0052] S1. Dissolve 3g of citric acid and 6ml of branched polyethyleneimine (50wt.% aqueous solution) with a mass average molecular weight of 2000 in 20ml of DMF, stir evenly, then place in a closed reaction kettle, and react for h at 160°C;

[0053] S2. Centrifuge the reacted solution in S1 for 3 times in a centrifuge at a speed of 8000r / min, remove insoluble polymers, and obtain a supernatant after centrifugation; transfer the supernatant obtained by centrifugation to the molecular weight cut-off Dialyze with deionized water for 5 days in a 3500 dialysis bag to obtain a dialysate, place the retained solution in the dialysis bag in a lyophilizer, lyophilize, and grind to obtain solid-state luminescen...

Embodiment 3

[0055] A solid-state luminescent carbon nano-dot is prepared by a solvothermal method using citric acid and a polyamine-based polymer as raw materials.

[0056] The preparation method of the above-mentioned solid-state luminescent carbon nano-dots comprises the following steps:

[0057] S1. Dissolve 3 g of citric acid and 4 g of linear polyethyleneimine hydrochloride with a mass average molecular weight of 4000 in 20 ml of water, stir evenly, then place in a closed reaction kettle, and react at 180° C. for 8 hours;

[0058] S2. Centrifuge the reacted solution in S1 for 3 times in a centrifuge at a speed of 8000r / min, remove insoluble polymers, and obtain a supernatant after centrifugation; transfer the supernatant obtained by centrifugation to the molecular weight cut-off Dialyze with deionized water for 5 days in a 3500 dialysis bag to obtain a dialysate, place the retained solution in the dialysis bag in a lyophilizer, lyophilize, and grind to obtain solid-state luminescent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fluorescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com